Services for Bare ceramic substrates

Our capabilities and services are as follows :

- Material:Aluminium Oxide,Zirconia Toughened Alumina (ZTA),Aluminium Nitride,Silicon Nitride;

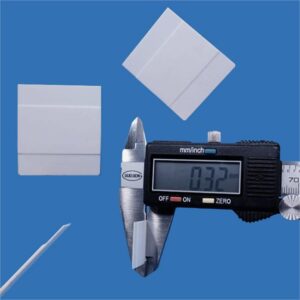

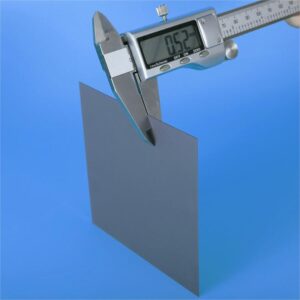

- Thickness:0.1~1mm,1.2mm,1.5mm;

- Production process: mainly tape casting,hot dry pressing (HDP);

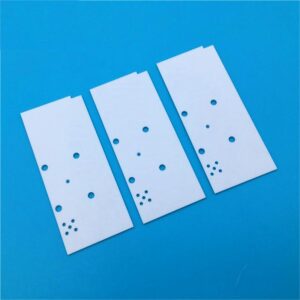

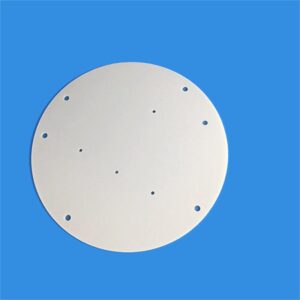

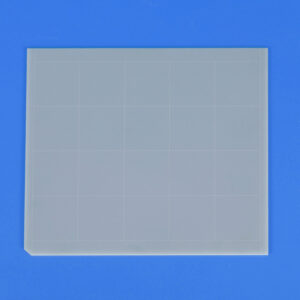

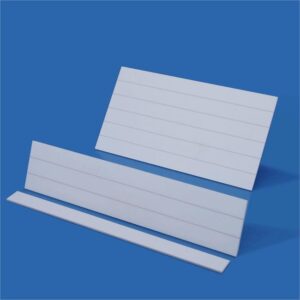

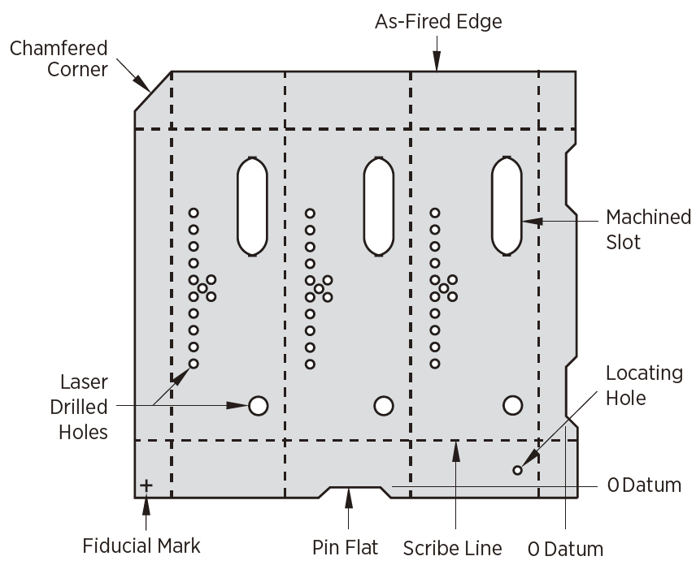

- Surface finishing: lapping, polishing, Laser scribing, laser cutting;

- Processing accuracy: can be controlled to 0.01mm.

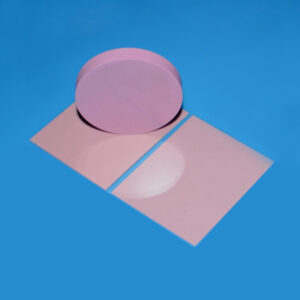

Customized sizes and color for You

Blank ceramic substrates are normally white, gray or beige, if you want other colors,we have a variety of stabilizers and colorants based on your requirements. Different sizes of bare ceramic substrates can be realised by laser scribing and laser cutting on larger substrates, or they can be supplied directly as individual pieces.

bare ceramic substrates Classification

Jinghui Ceramics can provide blank ceramic substrates in various materials and thickness.If you need to customize special substrates and have special requirements for dimensions, please contact us and give us a drawing to confirm, or you can use text to describe your needs and we will provide a drawing back to you for confirmation. We will be happy to provide you with technical analysis of the product and a competitive quotation.

alumina Ceramic substrates

Zirconia Toughened Alumina Substrates

Aluminium Nitride substrates

Silicon Nitride substrates

Main Properties for blank ceramic subsrates

Bare ceramic substrates are mainly made from alumina, ZTA,AlN, Si3N4. Different ceramic substrates made of different materials have different properties.

Mechanical

Strong mechanical stress, stable shape; high strength, high thermal conductivity, high insulation; strong bonding, anti-corrosion.

maching

The same as the PCB board (or IMS substrate) can be etched with a variety of graphic structures; non-polluting, non-polluting

thermal

substrates for heat dissipation/substrates for Better thermal cycling performance, cycle times up to 50,000 times, high reliability

simplifying

Wide operating temperature -55℃~850℃; coefficient of thermal expansion close to that of silicon, simplifying the production process of power modules.