About IGBT

The full name of IGBT is Insulated Gate Bipolar Transistor. It is a composite fully-controlled voltage-driven power semiconductor device and is recognized as a representative product of the third technological revolution of power electronics in the world.

IGBT has excellent performances such as high frequency, high voltage, high current, and easy switching. Its main function is to convert alternating current and direct current and convert high and low voltages. It is regarded as the "CPU" in the electronic control system. To put it simply, IGBT can adjust the voltage, current, frequency, phase, etc. in the circuit according to the signal instruction, just like a "switch" to achieve precise regulation.

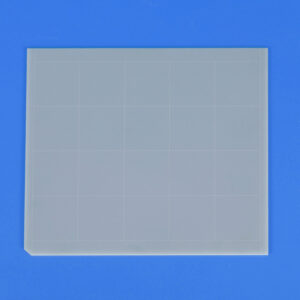

The thermal expansion coefficient of Si3N4 (Silicon Nitride) best matches that of semiconductor chips, its mechanical properties are more than 2 times that of Al2O3 (Alumina) and AlN (Aluminum Nitride), and its thermal conductivity is more than 2.5 times that of Al2O3. For high-power IGBT modules, silicon nitride is currently the best material.

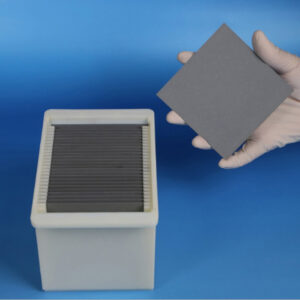

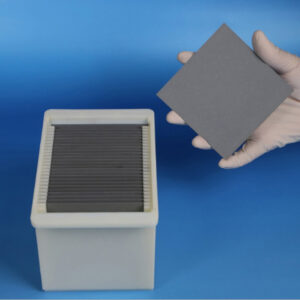

Why Choose Silicon Nitride Ceramic Substrate

Compared with aluminum nitride (AlN) and aluminum oxide (Al2O3), silicon nitride (Si3N4) ceramic substrates have obvious advantages in terms of current carrying capacity, heat dissipation capacity, mechanical properties, and reliability.

The thermal expansion coefficient of Si3N4 best matches that of semiconductor chips, its mechanical properties are more than twice that of Al2O3 and AlN, and its thermal conductivity is more than 2.5 times that of Al2O3. For high-power IGBT modules, silicon nitride is currently the best material.

Application of Silicon Nitride Ceramic Substrate in the Field of New Energy Vehicles

The heat dissipation efficiency requirements of automotive IGBTs are much higher than those of industrial grades. The temperature inside the inverter is extremely high, and strong vibration conditions must also be considered. The performance requirements of automotive grade IGBTs are far higher than those of industrial grades.

Because the silicon nitride substrate is suitable for automotive IGBT packaging, it can adapt to the high temperature and high pressure working environment, dissipate the high heat in the power system in time, protect the chip from normal operation, and prolong the service life of electronic equipment.