Advanced Ceramics Factory - High Quality Aluminum Oxide Al2O3 Ceramic Rings

The company can customize and produce various special-shaped aluminum oxide ceramic rings for customers. We select high-temperature-resistant ceramic ultrafine powder, with an Al2O3 content of 95% - 99.5%, using contemporary formulas, dry pressing, isostatic pressing or hot pressing molding processes, and fired in a high-temperature kiln at a temperature of about 1650°C.

The color of the product is pure white or yellowish, with high density, wear resistance, corrosion resistance, insulation, electric breakdown resistance, high temperature resistance and other characteristics. Applications include electronic appliances, mechanical seals, high voltage, high temperature, and parts that are easy to wear.

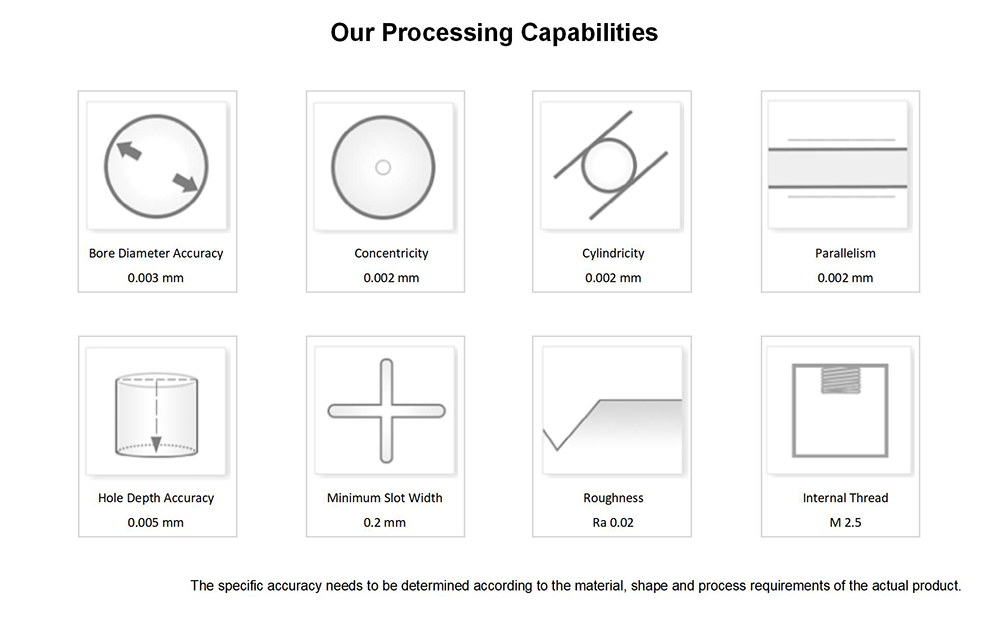

Methods for Realizing Precision Ground of Alumina Ceramic Rings

The purpose of precision ground is to achieve a high-precision and smooth grinding surface. There are several methods for achieving precision grinding of alumina ceramic rings:

1. Manual grinding: Use hand tools, such as grinding rods, grinding paper, etc., to grind the alumina ceramic ring step by step until the required precision is achieved.

2. Mechanical grinding: Use mechanical equipment such as grinding machines and grinding discs to precisely grind alumina ceramic rings by adjusting grinding parameters and using grinding liquid.

3. Chemical grinding: use chemical reaction to modify the surface of alumina ceramic ring, change its surface morphology and properties, so as to realize precision grinding.

Product Display

For more styles, please consult us.