Product Introduction

The nozzle is a key part, even the main part, of many kinds of mist spraying, oil spraying and sandblasting equipment. For example, the more common application is sprinkler irrigation equipment in agriculture.

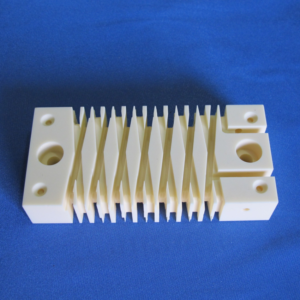

Nozzles are classified by material and can be divided into metal nozzles, plastic nozzles, ceramic nozzles, and alloy nozzles. Here we focus on introducing ceramic nozzles to you. Our ceramic nozzles are primarily made of alumina, zirconia and silicon nitride, which are high temperature resistant ceramic materials. Ceramic nozzles have the following characteristics:

1. High temperature resistance performance: The ceramic nozzle can work stably for a long time in a high temperature environment. Usually can withstand high temperature above 1000 ℃.

2. Wear resistance: The ceramic nozzle has high hardness and wear resistance, can resist particle erosion and wear, and has a long service life.

3. Corrosion resistance: The ceramic nozzle has excellent corrosion resistance, and can work stably for a long time in corrosive media such as acid and alkali without corrosion and erosion. Nozzles made of other materials are easily oxidized or corroded, and need to be replaced frequently. Therefore, ceramic nozzles are often used to spray chemical reagents.

4. Dimensional stability: The ceramic nozzle has a low thermal expansion coefficient, good dimensional stability, and is not easy to deform or break.

5. High precision: The ceramic nozzle is produced by advanced manufacturing technology, with complex shape and high precision, which is conducive to precise control of jet flow and jet direction.

Application of Ceramic Nozzles

Ceramic nozzles have the advantages of high temperature resistance, corrosion resistance and wear resistance, so they are widely used in the following fields:

1. Industrial spray: Ceramic nozzles can be used in industrial applications such as high temperature spray, high pressure spray and corrosive medium spray, such as metallurgy, chemical industry, petroleum, electronics and other industries.

2. Inkjet printing: Ceramic nozzles can be used in inkjet printers, which have the advantages of wear resistance, high resolution and long life.

3. Cooling nozzles: Ceramic nozzles can be used in cooling systems and air conditioning systems, with excellent thermal conductivity and high temperature resistance.

4. Sand blasting machine: Ceramic nozzles can be used in sand blasting machines for cleaning and surface treatment.

5. Gas nozzles: Ceramic nozzles can be used in gas injectors with high temperature resistance and corrosion resistance.

6. Medical equipment: Ceramic nozzles can be used in medical equipment, such as dental sandblasting machines, laser atomizers, etc.

Why Choose Us

As a manufacturer of ceramic nozzles, we have the following advantages:

1. High-quality materials: We use high-purity ceramic materials to manufacture nozzles, which have excellent wear resistance, high temperature resistance, and corrosion resistance, and can operate stably for a long time in harsh working environments.

2. Precision processing technology: We have advanced processing equipment and technology, which can accurately control the size and shape of the nozzle, ensure the stability and consistency of the nozzle, and improve the spraying effect.

3. Diversified styles: We provide a variety of ceramic nozzles, which can be customized according to customer needs in different shapes, apertures, angles and other parameters to meet the spraying requirements of different application scenarios.

4. Quality assurance: We strictly control the production process and implement a comprehensive quality management system to ensure that each nozzle meets high-standard quality requirements and provide reliable products to customers.

5. Professional team: We have experienced engineers and technicians who can provide professional technical support and after-sales service to quickly solve customer problems and needs.