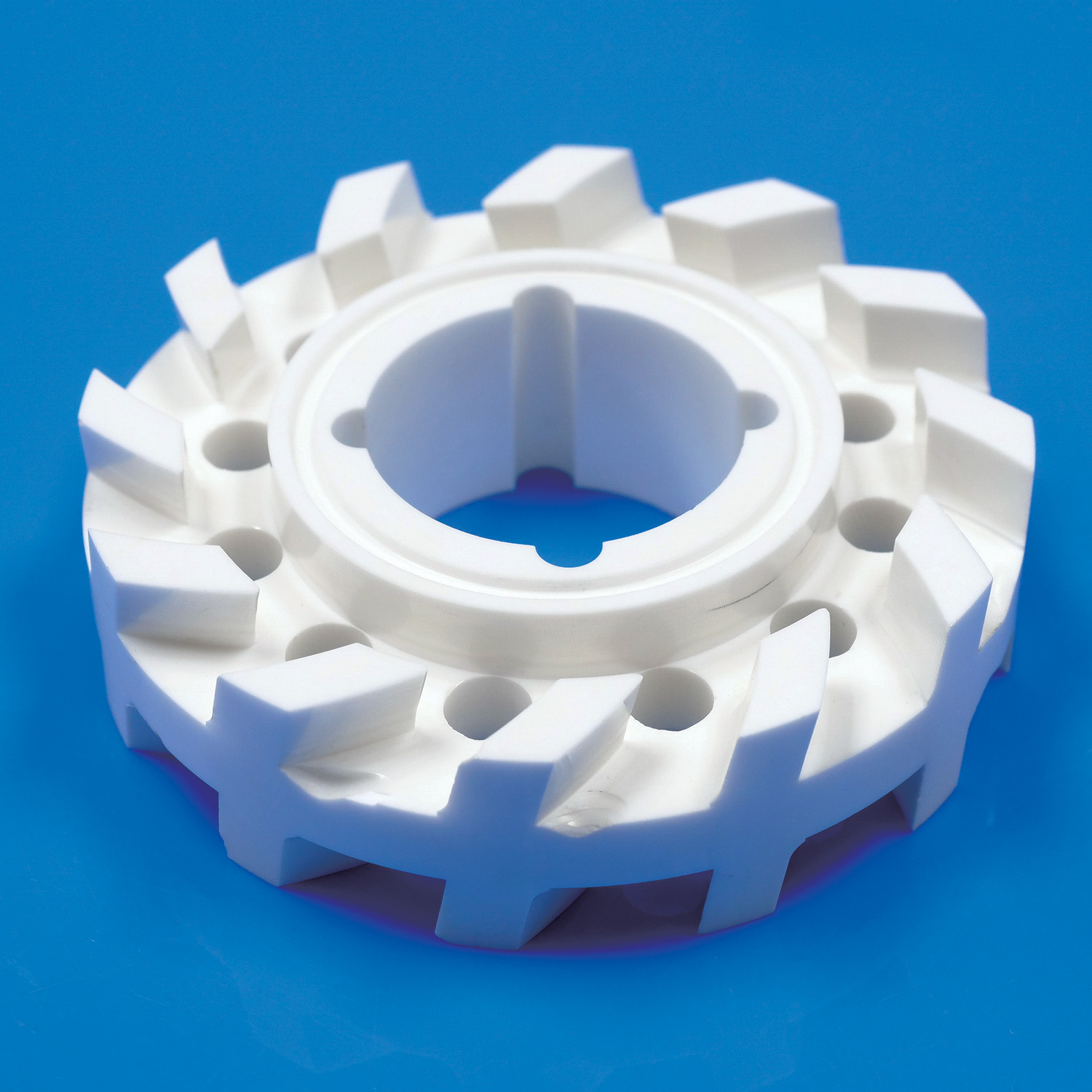

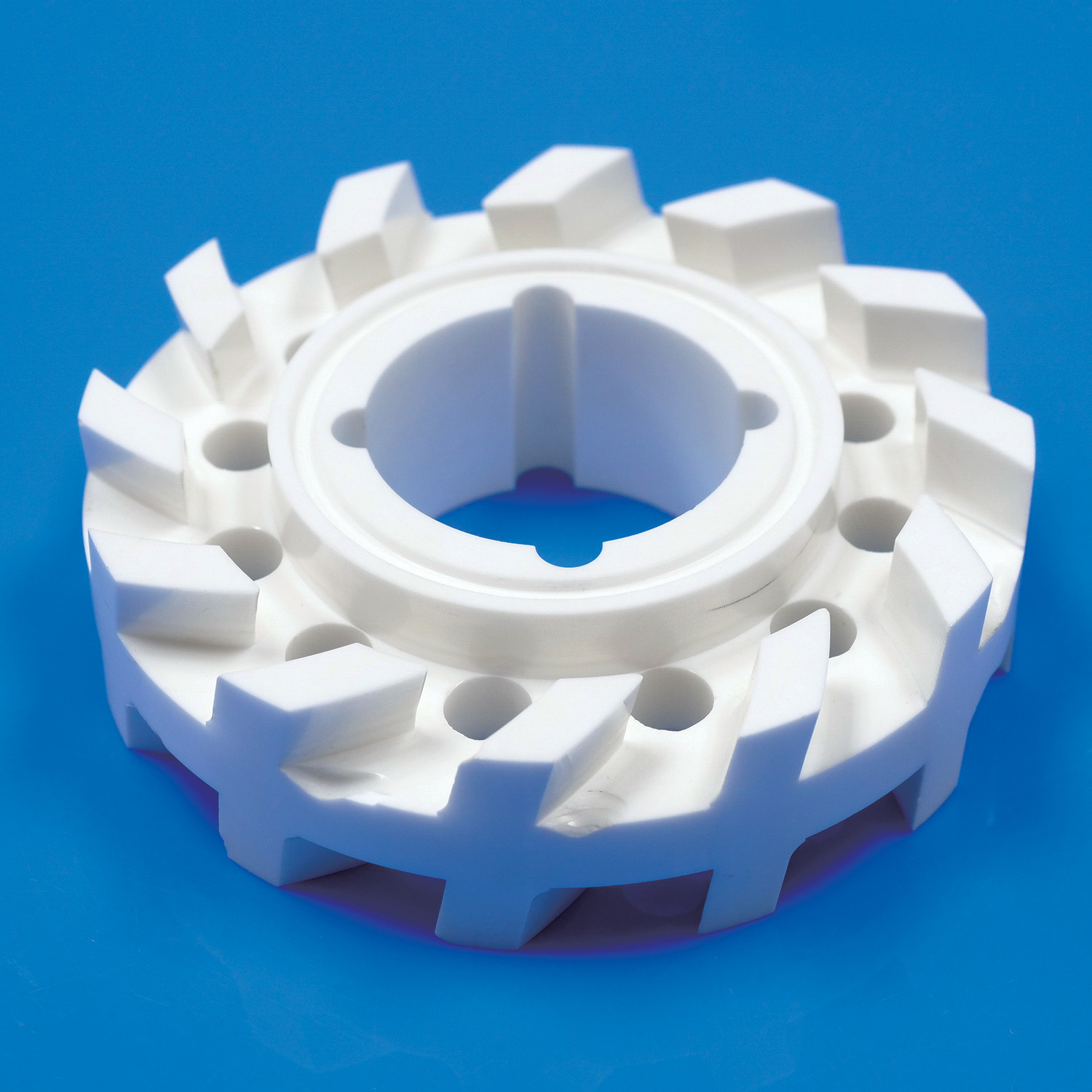

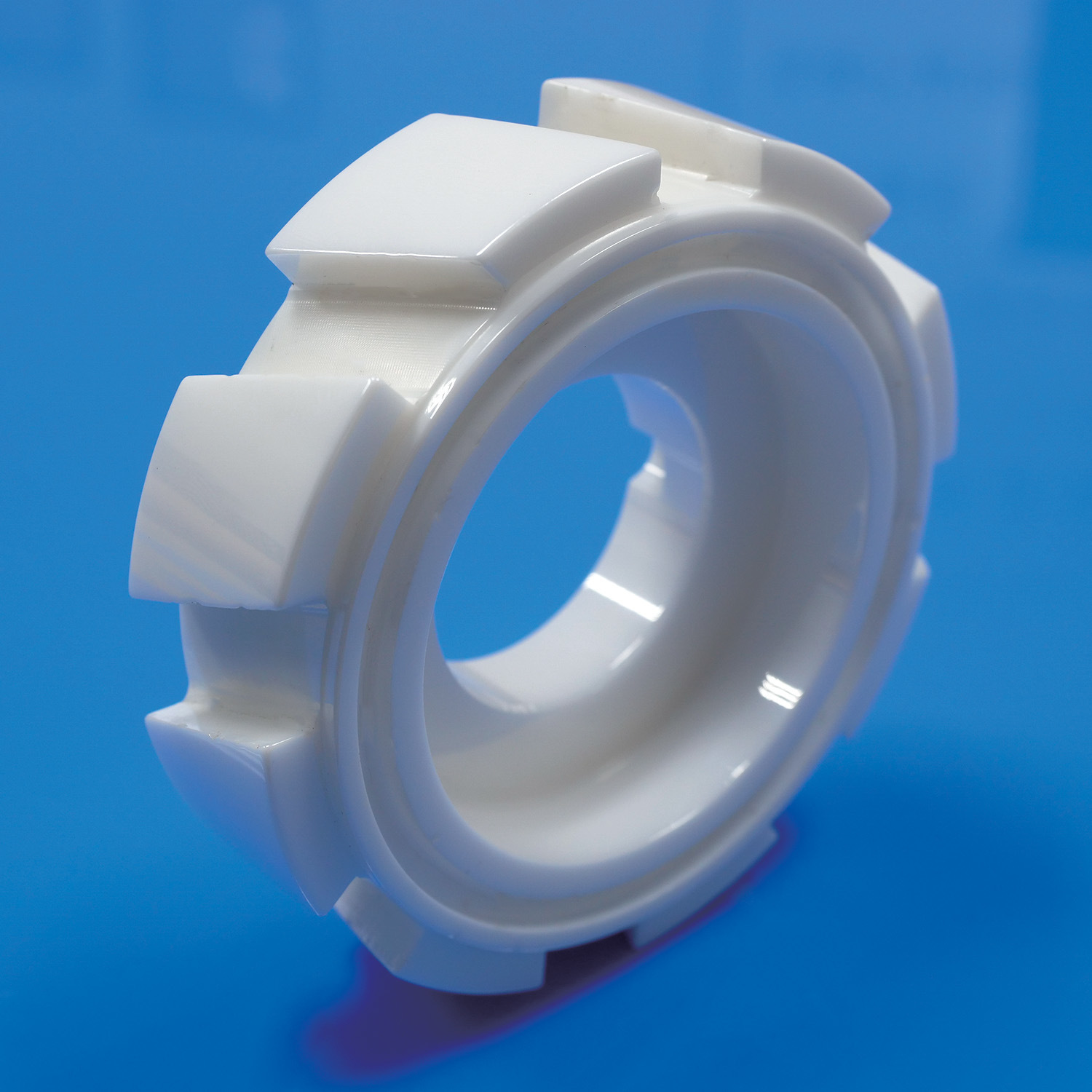

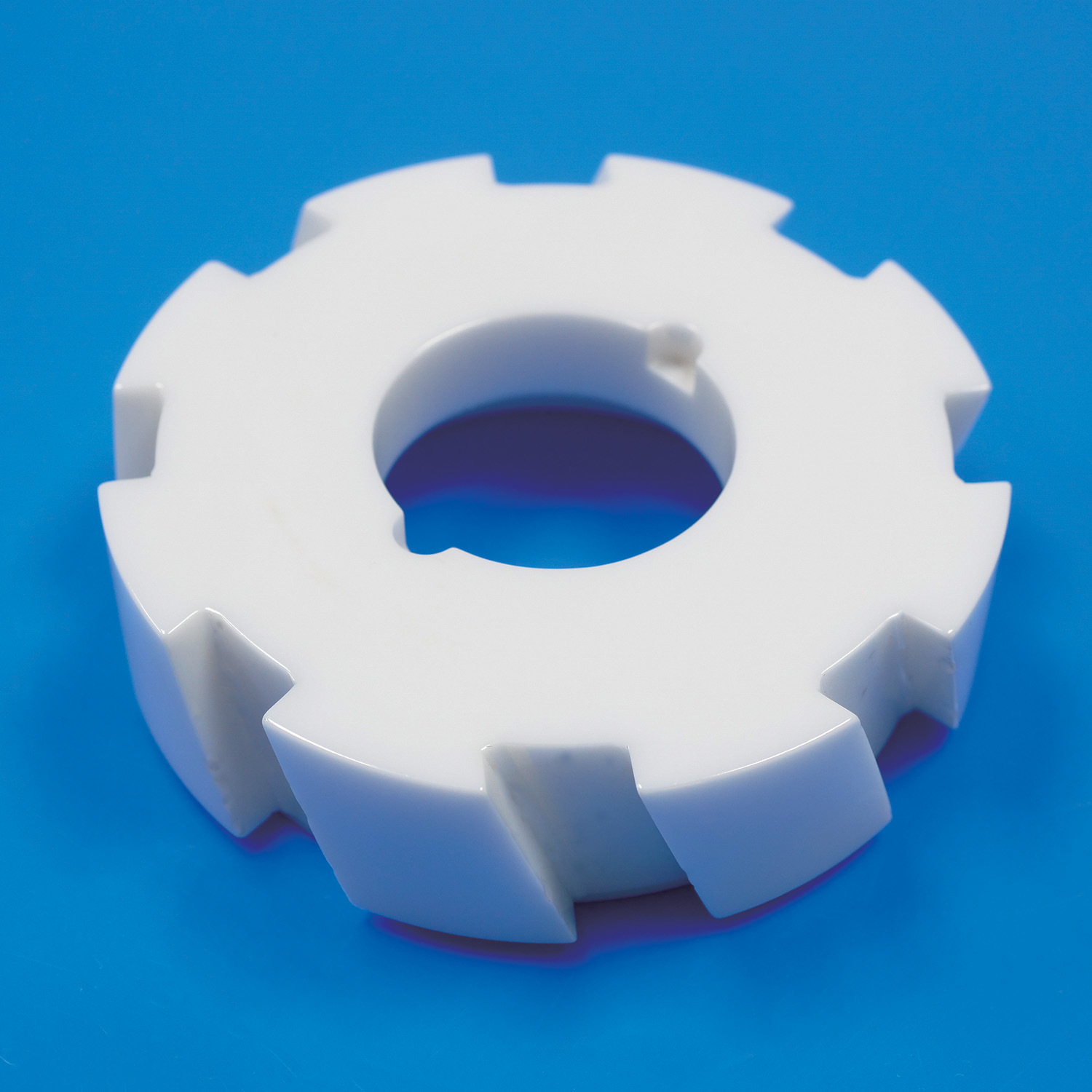

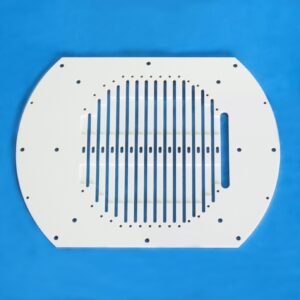

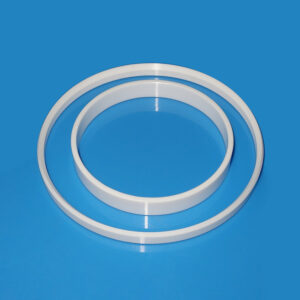

Super Wear Resistant Machined Zirconia Sand Mill Ceramics

The main features of high precision ceramic parts

1. High precision dimensions with tightening tolerance, it's easier to get a perfect fitting relationship

2. Wear & abrasion resistance: Alumina is an extremely hard technical ceramic with superb wear resistance

3. High-temperature ability: withstand up to 1650°C in oxidizing and reducing atmospheres

4. Chemical inertness, resistant to most of the strong acid and alkali, and does not rust forever

5. Electrical insulation: The insulation breakdown is up to 18KV at least

6. Great mechanical properties, hardness, compressive and flexural strength are much higher stainless steel

7. Chemical corrosion resistance under high temperature, even if with strong acid or alkali

8. Protective atmospheres or high vacuum at high temperatures to eliminate contamination or impurity.

9. Low material cost in high-level applications than other technical ceramics

The specification of ceramic parts

| Material option |

Alumina(Al2O3), Zirconia (ZrO2), Silicon carbide(SiO2), Silicon nitride(Si3N4) |

| Forming methods |

ISO pressed, Dry pressed, Ceramic injection molding, Hot pressed |

| Specification |

OD can be from 1 to 50mm, length can be from 10mm to 800mm |

| Precision processing |

CNC machining, Precision grinding, Polishing, Lapping, |

| Tolerance |

The tolerance of OD and ID can be 0.001mm, the tolerance of length can be 0.001mm |

| Key parameters |

Roughness to be 0.02mm, Flatness to be 0.001mm, Parallelism to be 0.001mm |

| Surface quality |

Free of cracks, foreign contamination, mirror surface better than Ra0.1 |

The description of high precision alumina ceramic parts

Alumina (Al2O3) is a hard-wearing technical ceramic material frequently used in a broad range variety of industries applications. After firing and sintering, the alumina ceramic parts can only be precisely machined using diamond-grinding methods. It's charactered by high tighten tolerance, high hardness and wear resistance, low erosion levels, high-temperature resistance, corrosion resistance, and chemical stability. Furthermore, it can be highly polished making it a mirror surface to reduce friction at the fitting, working status.

We offer a selection of purities ranging from 95 - 99.8%. Our factory has access to many different types of shaping methods, including dry pressing, hot pressing, ceramic injection molding, ISO pressing, tape casting, and extruded.

Our facility is capable of machining a variety of complicated ceramic parts with a very high accuracy dimension through fine grinding, lapping, CNC machining, laser cutting, and so on.

The gallery of high precision ceramic parts

Datasheet of Technical ceramics

| Property |

Units |

Material |

99.5%

alumina |

99%

alumina |

95%

alumina |

ZrO2

(Y-TZP) |

ZrO2

(TTZ) |

| Density |

g/cm3 |

≥3.85 |

≥3.80 |

≥3.60 |

≥5.95 |

≥5.72 |

| Water absorption |

% |

0 |

0 |

0 |

0 |

0 |

| Hardness |

HV |

1700 |

1700 |

1500 |

1300 |

900 |

| Flexural strength |

Mpa |

≥379 |

≥338 |

≥320 |

≥1200 |

≥1200 |

| Compressive strength |

Mpa |

≥2240 |

≥2240 |

≥2000 |

≥1990 |

1750 |

| Fracture toughness |

Mpa m1/2 |

4-5 |

4-5 |

3-4 |

6.5-8 |

11 |

Max. service

temperature |

ºC |

1675 |

1600 |

1450 |

1000 |

|

| CTE |

1×10 -6 /ºC |

6.5~8.0 |

6.2~8.0 |

5.0~8.0 |

8.0~9.5 |

10.2 |

| Thermal shock |

T(ºC) |

≥250 |

≥200 |

≥220 |

≥300 |

350 |

| Thermal conductivity(25ºC) |

W/m.k |

30 |

29 |

24 |

3 |

3 |

| Volume resistivity |

ohm.cm |

|

|

|

|

|

| 25ºC |

>1 x 10 14 |

>1 x 10 14 |

>1 x 10 14 |

>1 x 10 11 |

>1 x 10 11 |

| 300ºC |

1 x 10 12 |

8 x 10 11 |

10 12 -10 13 |

1 x 10 10 |

1 x 10 10 |

| 500ºC |

5 x 10 10 |

2 x 10 9 |

1 x 10 9 |

1 x 10 6 |

1 x 10 6 |

| Insulation strength |

KV/mm |

19 |

18 |

18 |

17 |

20 |

| Dielectric constant(1Mhz) |

(E) |

9.7 |

9.5 |

9.5 |

29 |

28 |

Our capability and strength

We have in-housing comprehensive manufacturing types of equipment, including forming, sintering,

CNC machining, precision grinding, laser cutting, and so on, it helps us to control the quality very well.

Also, it greatly benefits cost control.

The state of the art manufacturing equipment

Rigorous Quality-control System

Remark:

We have the complete quality-control system per ISO9001, including IQC, IPQC, QA, and OQC process.

Typical Packaging Proposal and Transportation Methods

1. Packaging proposal

2. Regular Transporation Methods

FAQs (Frequently Asked Questions)

Q1. Are you a factory or trading company?

A: We are a manufacturer with over 12 years of experience. You are welcome to visit our factory.

Q2: Do you send a sample to check?

A: Sure, the sample is free and freight collect.

Q3: When will you ship it?

A: If the products are in storage, we'll ship within 48 hours

Q4: When can I get the price?

A: We regularly quote within 24 hours after we get your inquiry. If you are in urgent need of getting the price.

Please call us or tell us in your email so that we will proceed with your inquiry as a priority.

Q5: Is it available to provide customized products?

A: We always support custom-made demand as per different materials, dimensions, and designs.