Jinghui Ceramic has focused on industrial ceramics for 15 years. We have mature production technology, lower scrap rate and cheaper prices. We have one-stop services for molding, sintering, and precision machining. No outsourced assistance is required, and the delivery time is shorter and more controllable. We attach great importance to customers' experience, provide customers with timely and reliable after-sales service, and solve problems encountered by customers during the use of products.

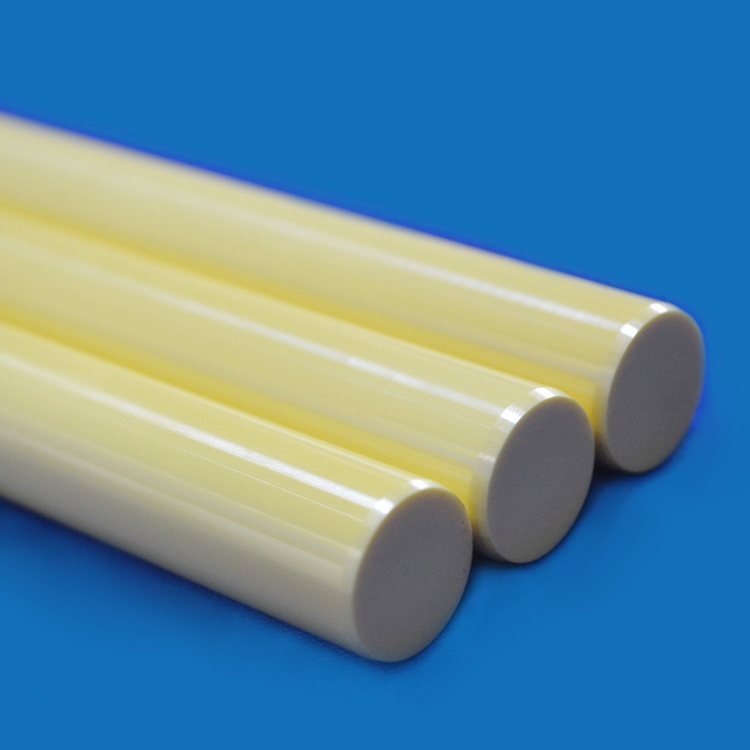

In the production of zirconia ceramic shaft rod, the materials we use are mainly Y-TZP (Y2O3 Stabilized Zirconia) and Mg-PSZ (MgO Stabilized Zirconia). They have many characteristics such as high strength, high temperature stability, good chemical stability and good optical properties, so they have a wide range of applications and provide high-quality material options for manufacturing, biomedicine, aerospace and other industries. At the same time, with our precision machining production capabilities, we are able to provide different levels of precision zirconia ceramic parts to meet customers' high-precision assembly needs.

Specification of our zirconia ceramic shaft rod

| Name |

Zirconia ceramic shaft rod |

| Forming method |

Dry Pressing, Hot Pressing, Ceramic Injection Molding (CIM) or Isostatic Pressing |

| Specification |

OD: 1 mm to 50 mm; Length: 10 mm to 800 mm |

| Precision processing |

CNC machining, Precision grinding, Polishing, Lapping |

| Tolerance |

Tolerance of OD and tolerance of length to be 0.001 mm |

| Key parameters |

Roughness to be 0.02 mm; Parallelism to be 0.001 mm |

| Surface quality |

Free of cracks and foreign contamination; Mirror surface better than Ra 0.1 |

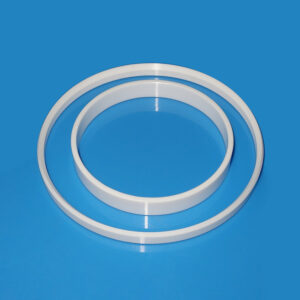

The gallery of our zirconia ceramic parts

Datasheet of Technical ceramics

| Property |

Units |

Material |

99.5%

alumina |

99%

alumina |

95%

alumina |

ZrO2

(Y-TZP) |

ZrO2

(Mg-PSZ) |

| Density |

g/cm3 |

≥3.85 |

≥3.80 |

≥3.60 |

≥6.0 |

≥5.72 |

| Water absorption |

% |

0 |

0 |

0 |

0 |

0 |

| Hardness |

HV |

1700 |

1700 |

1500 |

1300 |

1200 |

| Flexural strength |

Mpa |

≥379 |

≥338 |

≥320 |

≥1200 |

≥900 |

| Compressive strength |

Mpa |

≥2240 |

≥2240 |

≥2000 |

≥1990 |

≥1750 |

| Fracture toughness |

Mpa m1/2 |

4-5 |

4-5 |

3-4 |

6.5-8 |

11 |

Max. service

temperature |

ºC |

1675 |

1600 |

1500 |

1000 |

1200 |

| CTE |

1×10 -6/ºC |

6.5~8.0 |

6.2~8.0 |

5.0~8.0 |

8.0~9.5 |

7.8~9.3 |

| Thermal shock |

T(ºC) |

≥200 |

≥200 |

≥220 |

≥300 |

≥300 |

| Thermal conductivity (25ºC) |

W/(m·k) |

30 |

29 |

24 |

3 |

2 |

| Volume resistivity |

ohm·cm |

|

|

|

|

|

| 25ºC |

>1 x 10 14 |

>1 x 10 14 |

>1 x 10 14 |

>1 x 10 13 |

>1 x 10 13 |

| 300ºC |

1 x 10 12 |

8 x 10 11 |

10 12 -10 13 |

1 x 10 10 |

1 x 10 10 |

| 500ºC |

5 x 10 10 |

2 x 10 9 |

1 x 10 9 |

2 x 10 5 |

2 x 10 5 |

| Insulation strength |

KV/mm |

19 |

18 |

18 |

17 |

9.4 |

| Dielectric constant (1Mhz) |

(E) |

9.7 |

9.5 |

9.5 |

29 |

28 |

Our capability and strength

We have in-housing comprehensive manufacturing equipment, including forming, sintering, CNC machining, precision grinding, laser cutting, etc. It helps us to control the quality very well. Also, it greatly benefits cost control.

1. Display of some equipment

2. Rigorous Quality-control System

Remark: We have the complete quality-control system per ISO9001, including IQC, IPQC, QA, and OQC process.

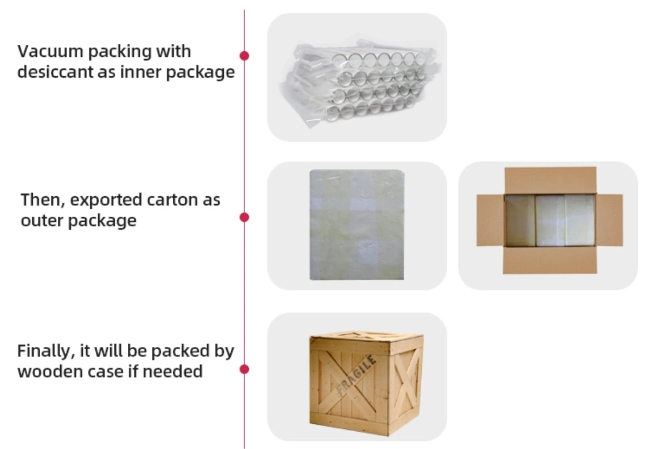

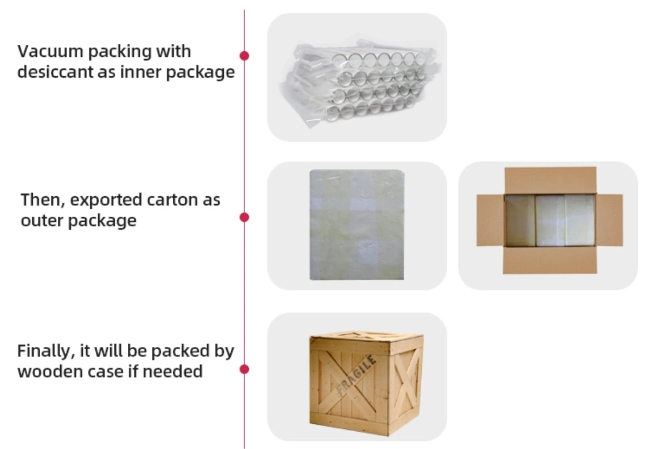

Typical Packaging Proposal and Transportation Methods

1. Packaging Method

2. Regular Transportation Method