Eco-friendly Ceramic Grinding Burr

The grinding burrs, also called as grinding cores, work as the heart of seasoning and coffee grinders. Nowadays, advanced ceramic type grinding mechanism is one of most popular choice in the various seasoning mills and coffee makers.

We focus on manufacturing a great many of standard and custom made ceramic grinding burrs in the past decades with carefully selected materials, the optimized production equipment and rigorous quality control every link to ensure the high-performance, ideal consistency and cost competition. All materials of ceramic grinders we have been using have been certified by FDA, LFGB and EEC. It proves our products to be trustworthy.

We are not only supply ceramic grinding burrs but also provide pepper mill mechanisms to meet the different needs of customers. Our customer service team is always ready to provide you with excellent service. If you need high-quality, high-efficiency, environmentally friendly ceramic grinding burrs and mechanisms, please contact us today, and you will experience our professional service.

Table of Contents for this Page

It is not easy to introduce all aspects of Ceramic Grinding Burrs, so we have prepared a lot of information on this page for you to delve into. To make sure you can find the information you want quickly, we have prepared this content directory that will jump to the corresponding location when you click on it.

the Typical Applications

Our products are suitable for a diversity of seasoning grinders for grinding food ingredients such as peppercorns, sea salt, spice seeds, herbs or for coffee mills and coffee machines for grinding coffee beans.

Hot Products Display

We classify Ceramic Grinding Burrs into three types:

1) Ceramic Burrs for Seasoning Grinder

2) Ceramic Conical & Flat Burrs for Coffee Grinder

3) Pepper Mill Mechanism

If you can not find the product you need hereby, please feel free to contact us!

Looking for grinding burrs in different materials?

In addition to ceramic burr pepper mill mechanism, we also have both stainless steel burr and carbon steel burr pepper mill mechanisms. Click the photo on the right to learn more.

Reference Cost Analysis

There are mainly the following 4 factors that affect your purchase cost, which need to be carefully considered before you place a purchase order.

1. Purchase Price

- Main cost;

- Influencing factors: production process, raw material cost, order quantity and customization requirements.

2. Transportation Cost

- Choosing: by express, by air, by sea,by train or truck;

- Considering: weight & volume of goods, delivery deadlines, shipping costs, and shipping safety.

3. Tariffs and Taxes

- Relatively fixed cost;

- Related factors: customs code, national policies and agreements, the value of imported goods and types of imported goods.

4. Quality Cost

- Hidden costs;

- Including: returns, replacements, repairs, etc;

- Our quality is reliable, almost no quality problems.

Estimated Lead Time

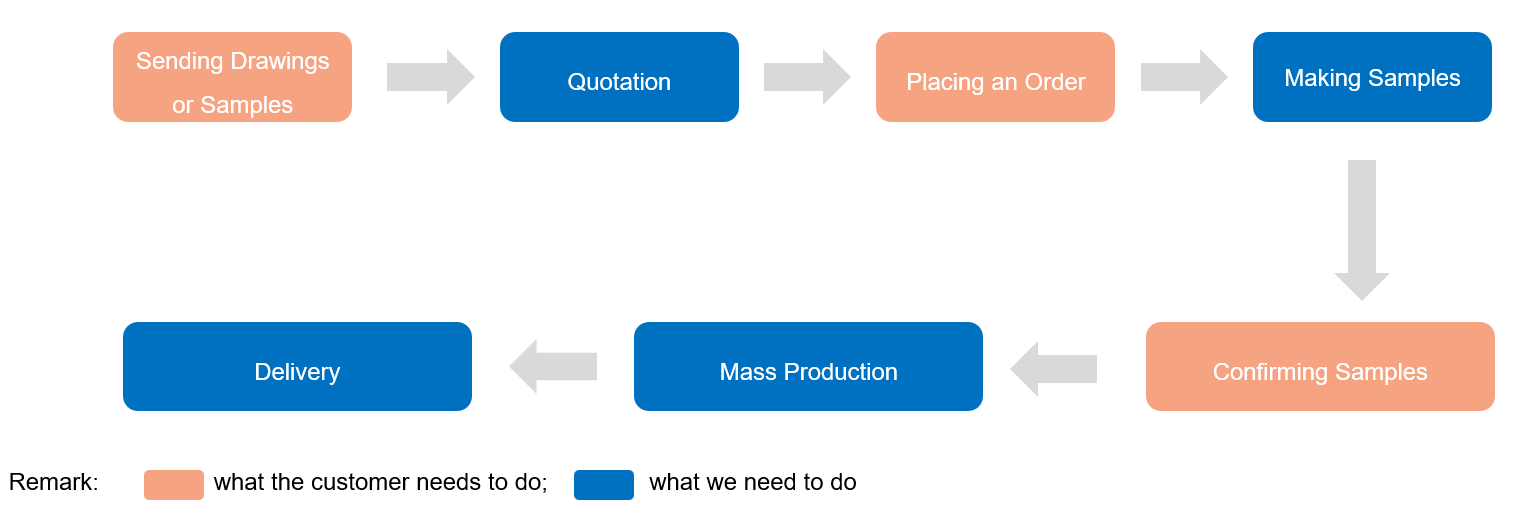

1. Customization order flow chart

2. How long does it take from placing an order to receiving the goods?

(1) Delivery time: If the product is in stock, we will ship it within 2-3 working days. The standard lead time for customized orders is 4-6 weeks.

(2) Transportation time: It depends on the shipping method. If you need the goods urgently, it is preferable to use express delivery. Under normal circumstances, It can be delivered in 3~7 days by international express.

Want to know how to compress lead times?

If you are not satisfied with the delivery time or need us to expedite the shipment, please contact our sales in time to communicate.

the Basic Knowledge

1. About ceramic grinding burrs

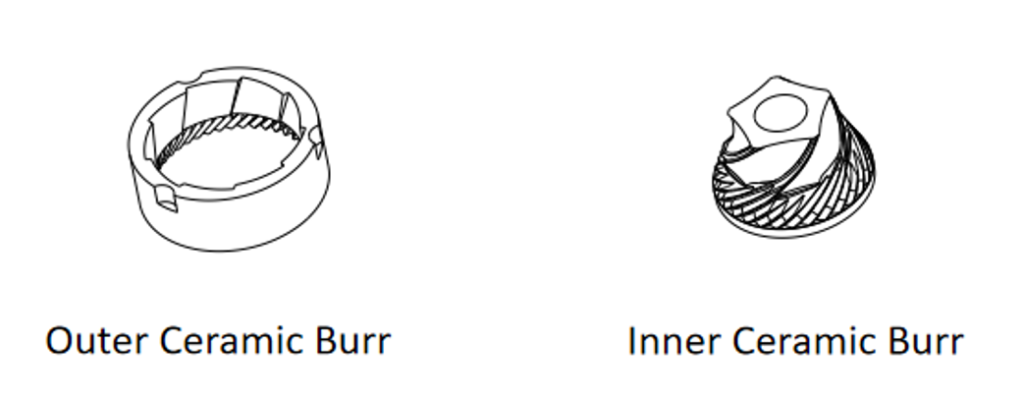

1.1 Working principle

It looks like a fluted cone that fits inside a fluted ring, like a drill bit with rows of teeth.

First, the seasonings is split in half by the coarse teeth. They are then crushed into smaller particles again between the fine teeth as they travel down between the inner and outer burr.

An adjustable screw on the top or bottom of the grinder tightens or loosens the spring to move the inner burr closer or farther away from the outer burr, thus changing the grain size of the pepper, salt and spice powder.

1.2 Main characteristics

Ceramic grinding burrs have the characteristics of wear resistance, corrosion resistance,eco-friendly, less heat generate at grinding process, and will not affect the flavor of food, but much longer service lifespan.So they have great development potential in the field of grinders.

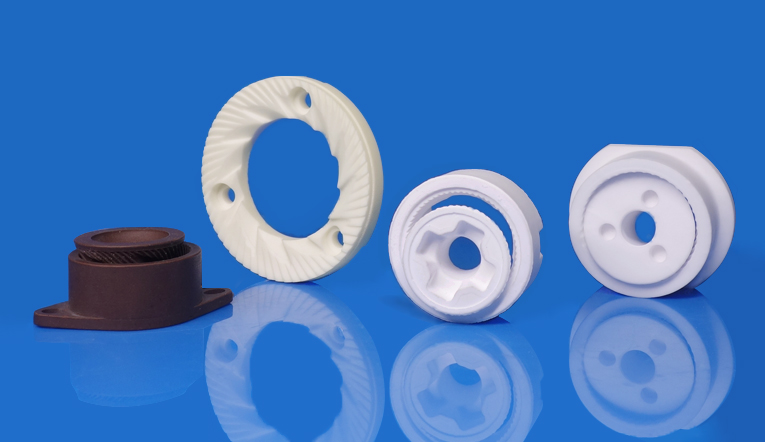

1.3 Material selection

The most common materials for ceramic grinding burr are 95% alumina and steatite. The burr in reusable grinders usually is made from alumina, while the burr in disposable grinders is made out of steatite.

① Alumina

High-purity alumina is widely used in the manufacture of reusable grinding cores. This material has excellent performance in wear resistance, corrosion resistance and environmental protection.

② Steatite

Steatite is another advanced ceramic. It has moderate mechanical strength and costs less than alumina ceramics.

Comparison of Material Properties

| Mechanical Property | 95% Al2O3 | MgO.SiO2 (Steatite) |

|---|---|---|

| Density (g/cm3) | ≥3.65 | ≥2.70 |

| Water absorption (%) | 0 | 0 |

| Hardness (HV) | 1500 | 800 |

| Flexural strength (Mpa) | ≥320 | ≥190 |

| Compressive strength ( Mpa) | ≥2000 | ≥551 |

| Fracture toughness (Mpam1/2) | 3-4 | - |

2. About the grinder kit

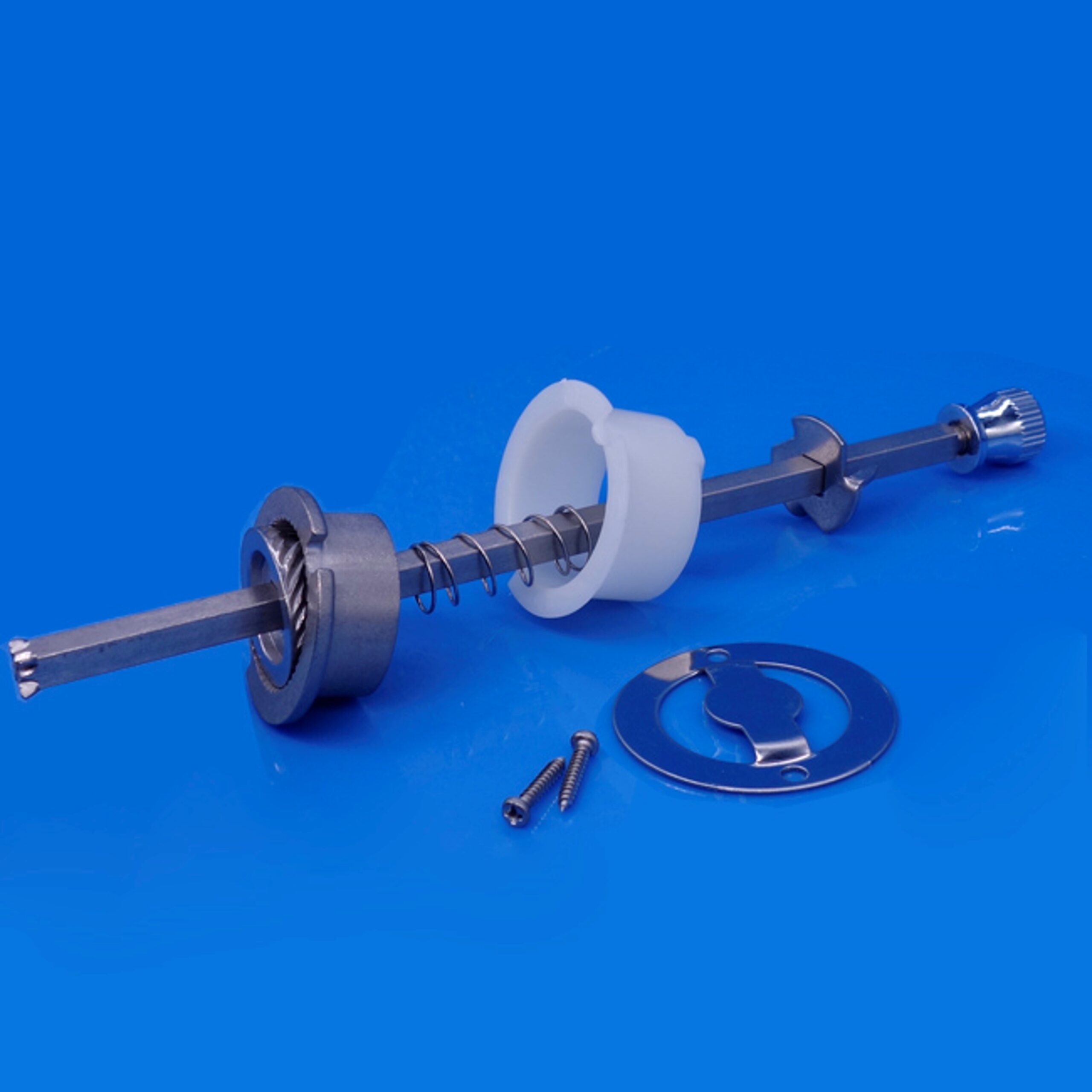

2.1 Common styles of grinder kits

Pepper mills on the market are available in a number of styles: knob twist, ratchets and cranks. The following are the styles produced by our company.

Classic

A Set Contains

Top knob: 1 pc

Shaft: 1 pc

Retainer: 1 pc

Housing: 1 pc

Spring: 1 pc

Ceramic burrs: 1 set

Screw: 2 pcs

Fixed plate: 1 pc

Knob Twist

A Set Contains

Cap: 1 pc

Shaft: 1 pc

Retainer: 2 pcs

Holder: 2 pcs

Housing: 1 pc

Ceramic burrs: 1 set

Spring: 1 pc

Adjustive knob: 1 pc

Knob Twist

A Set Contains

Shaft: 1 pc

Gasket: 1 pc

Ceramic burrs: 1 set

Spring: 1 pc

Adjustive knob: 1 pc

Ratchet

A Set Contains

Cap: 1 pc

Shaft: 1 pc

Retainer: 2 pcs

Holder: 3 pcs

Housing: 1 pc

Ceramic burrs: 1 set

Spring: 1 pc

Ratchet wheel: 1 pc

Crank

A Set Contains

Top knob: 1 pc

Shaft: 1 pc

Gasket: 1 pc

Housing: 1 pc

Spring: 1 pc

Ceramic burrs: 1 set

Screw: 2 pcs

Fixed plate: 1 pc

Crank handle: 1 pc

Crank

A Set Contains

Top knob: 1 pc

Shaft: 1 pc

Retainer: 1 pc

Housing: 1 pc

Spring: 1 pc

Ceramic burrs: 1 set

Screw: 4 pcs

Fixed plate: 1 pc

Crank handle: 1 pc

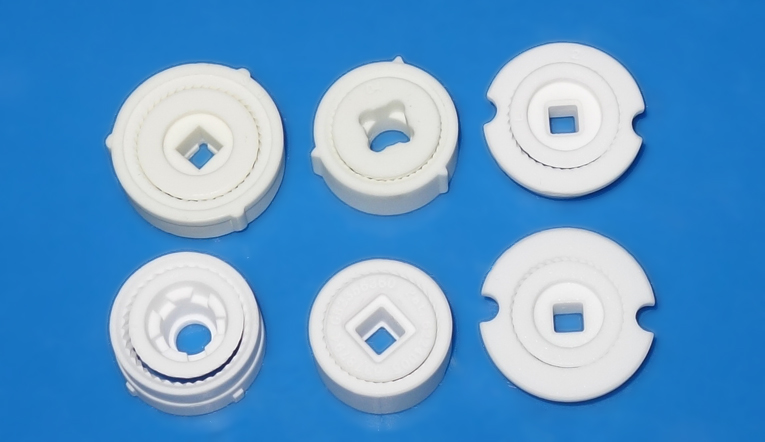

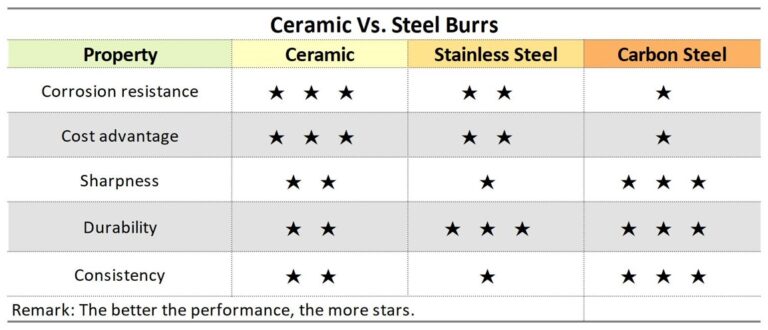

2.2 Type of grinding burrs

The type of grinding burr in the best seasoning generally includes ceramic, stainless steel, or carbon steel burrs. They have their own strengths and weaknesses in performance, you can choose according to your needs.

3. How to choose a grinder

3.1 Seasoning grinder

3.1.1 What food materials can be ground by the burr grinder

The ceramic grinding burr is suitable for grinding various seasonings, coarse cereals, herbs and spices, etc. You can refer to the applicable table below.

| Food materials you can grind | Small and uniformly shaped |

|---|---|

| Seasonings | Peppercorns like black pepper, white pepper, pink pepper and green pepper, chillis, sea salts |

| Coarse Cereals | Rices, wheats, linseeds, sesame seeds, soybeans, mung beans |

| Herbs and spices | Seeds of rosemary, mint, oregano, sage, thyme, parsley, basil, dill, clove, mustard, fennel, cardamom, cumin, cilantro, coriander, fenugreek, chive, star anise (crushed before grinding) |

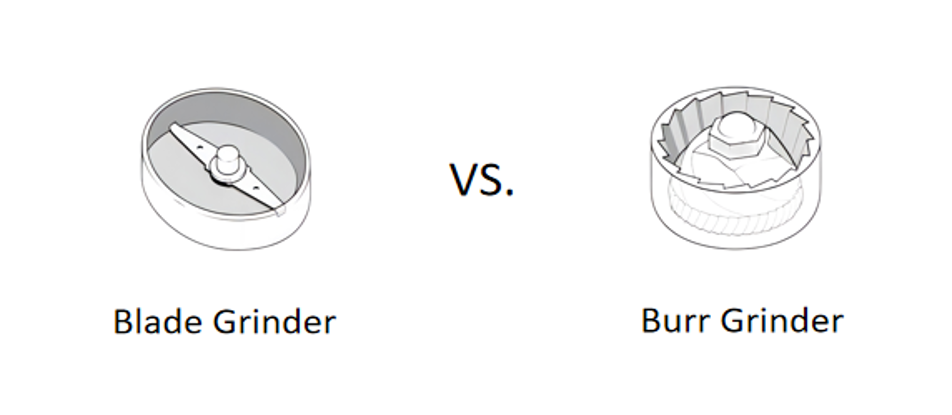

3.1.2 Burr grinders Vs. blade grinders

A blade grinder does not guarantee the same grinding quality as a burr grinder. This is because blade grinders chop food materials in a rough and irregular manner. Burr grinders, however, pulverize food materials into particles of consistent size.

3.1.3 Disposable seasoning grinder Vs. reusable seasoning grinder

Reusable grinder supports refilling. In contrast, the top of the disposable grinder cannot be unscrewed, so once the seasoning is used up, people just throw it away. Refer to the table below for their performance comparison.

| Reusable Seasoning Grinder | Disposable Seasoning Grinder | |

|---|---|---|

| PROS | Reusable | Easy to use |

| Consistent in grind sizes | No need to wash | |

| Totally recyclable | Cheap and affordable | |

| For the higher end market | For the low-end market | |

| CONS | Relatively expensive | Non-refillable / one-time use / disposable |

| Refilling may be troublesome | Doesn’t do well with grinding consistency | |

| Requires cleaning and maintenance | Difficult to recycle |

3.2 Coffee grinder

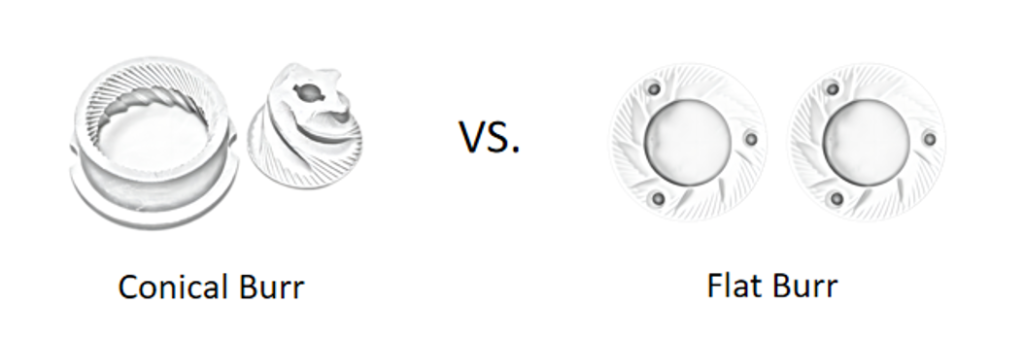

3.2.1 Conical burrs Vs. flat burrs

True coffee experts will tell you that the best way to grind coffee beans is with high-quality burrs. There are two main types of coffee grinders on the market: with flat burrs or with conical burrs.

Conical burrs: Common in entry-level electric grinders and hand grinders due to their smaller size. When it comes to espresso, conical burrs tend to produce a better tasting grind. Because of their smaller diameter, they are generally slower.

Flat burrs: Typically used in commercial coffee machines. They are convenient, fast, consistent, and efficient, but expensive.

3.2.2 Can the pepper grinder be used to grind coffee beans?

No. Even if you have a great pepper grinder with the ability to adjust the grind setting based on the size of the grind (note that a coffee bean is about 10 times the size of a peppercorn), there are still two issues to consider: It is difficult to precisely adjust to the original position when switching between the two grinds. Second, your coffee will taste like pepper!

3.2.3 Are manual coffee grinders better than electric ones?

It depends on your needs. If you brew a lot of coffee, you’ll love the convenience of an electric grinder. However, for smaller brews, hand grinders are a good option, and they’re cheaper, quieter, smaller, and portable.

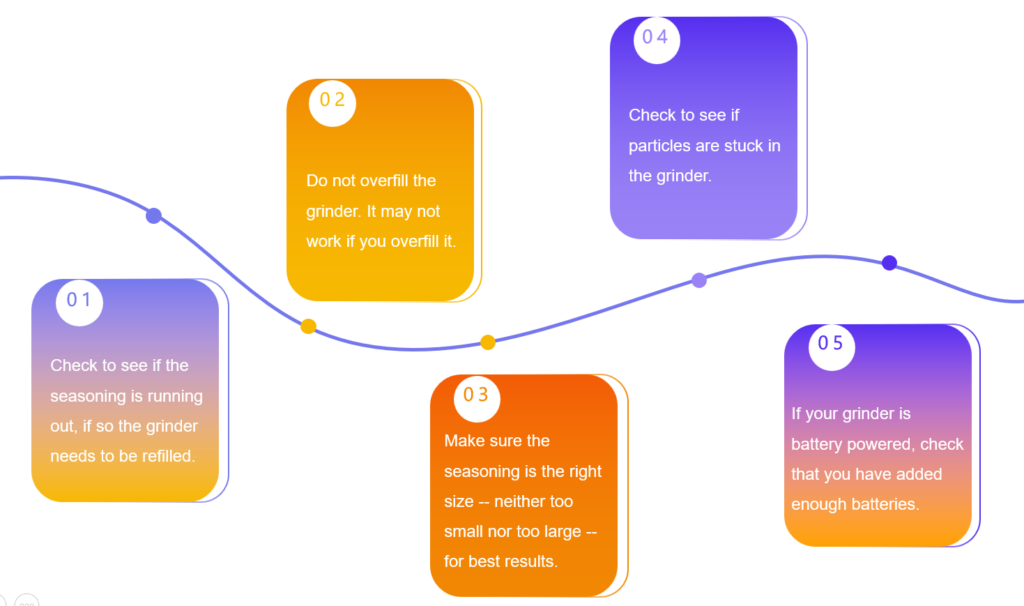

3.3 Simple troubleshooting

If your grinder is not working properly, you can refer to the following solutions.

3.4 How to clean

Clean the exterior of any grinder with a dry or slightly damp soft cloth. To clean the inside, use a soft, dry small brush to gently brush off any debris. If it gets wet, be sure to wipe it dry immediately after cleaning.

the Future Trends

The future development trend of ceramic grinding burrs mainly has the following directions.

AI Technology

By learning the user’s grinding habits and taste preferences, it can automatically adjust the grinding degree and speed to achieve a more personalized grinding effect.

Green and Environmental Protection

Made of biodegradable bio-ceramic materials, or made of recycled ceramic materials to reduce the impact on the environment.

Self-cleaning Design

Through the built-in cleaning device or automatic cleaning program, the grinding burrs can be cleaned and maintained more conveniently, and the life of the grinder can also be improved.

Why Choose Us

As a manufacturer of ceramic grinding burr, we have the following strengths:

FAQs

The FAQs (Frequently Asked Questions) column is designed to provide users with fast and convenient answering services. We hope that through the FAQs column, we can help you better understand our products and services. If you have any suggestions or comments on the FAQs column, please feel free to contact us.

1.Can the product be customized?

Yes, the ceramic grinding mechanism, the driven shaft and metal top knob can be made per customer’s specification, but with minimum order quantity.

2.Is it possible to provide samples before bulk orders? Is there a fee?

We are very willing to provide samples for customers to reduce your purchasing risk. Stock items can be shipped within 2-3 working days; Standard samples in stock are free, and mold charge is needed for customized samples.

3.What certifications do you have?

As of May 2023, for ceramic grinding burrs and kit products, our company has obtained the following certifications: US FDA certification, German LFGB certification, EU standards 84/500/EEC and 2005/31/EC for ceramic food contact materials and EU Food Contact Material Safety Regulation 1935/2004 certification. Obtaining three international certifications proves that our quality is safe and reliable.

In addition, our company has passed the ISO9001 quality management system certification, and can provide you with expected and satisfactory qualified products continuously and stably.

4.How will you solve the problem that the product quality does not meet expectations?

Our company has been focusing on quality and service. If the product quality does not meet the contract requirements, our company will immediately arrange to re-produce qualified products; if we cannot provide qualified products, we will arrange refunds.

5. How to deal with the damage in transportation?

All of our products are packed in safe packages suitable for long-distance transportation, which are not easy to be damaged; in case of damage, please cooperate with our company and logistics company to go to claim process at the first moment, and then our company will arrange replenishment.

6.What other products do you manufacture?

After 15 years’ development, four main advantageous product series have been built, they are metallized ceramic products, ceramic grinding burrs, ceramic substrates and engineering ceramics respectively. In addition, we also supply ceramic plates, ceramic tubes, thermostat ceramics, ceramic seals, textile ceramics, spark plug insulators etc. All of our products can be customized, and we not only provide prototyping samples but also mass production services.