Electric vacuum devices are often called electron tubes, also known as vacuum electronic devices. Semiconductor devices are mainly used under low frequency and low power conditions, but under high power and high frequency conditions, such as in the military field, electronic jamming, early warning aircraft, fire control radar, precision guidance and other systems are inseparable from vacuum microwave tube devices. Microwave vacuum electronic devices are responsible for 90% of sending radar, communication and interference signals.

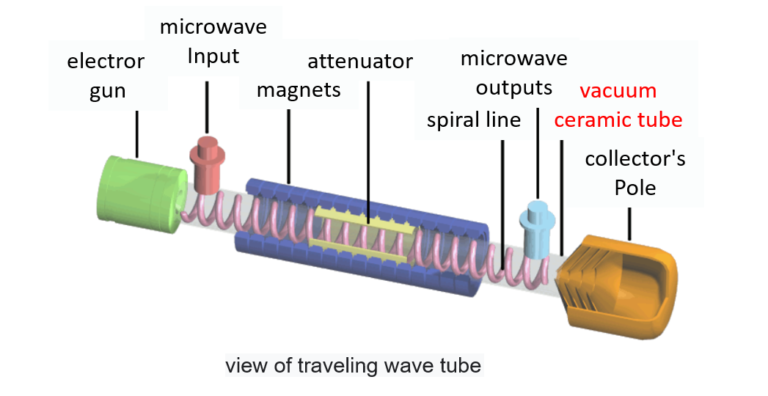

Vacuum electronic devices mainly include: broadband high-power traveling wave tubes, grid-controlled traveling wave tubes, millimeter wave devices, orthogonal field amplifier devices, vacuum microelectronic devices, etc., which are used in many fields of the national economy and have high reliability and long life. , low noise, wide band, high power, miniaturization, etc. all involve the improvement of material quality and the development of new materials.

The general requirements for vacuum electronic device materials are as follows:

1) Good vacuum airtightness Vacuum electronic devices work in a high vacuum (10^-5~10^-6 Pa) state and have high requirements for the airtightness of the material, that is, the material itself should be airtight. Gas parts must not be released under working conditions, especially harmful gases.

2) Strict impurity control Vacuum electronic devices are very sensitive to impurities in all materials, and impurities directly affect the performance parameters and reliability of the device.

3) Good processing performance requires updated materials with the development of devices. For example, some millimeter wave devices have begun to make tubes, and the processing accuracy has reached micron level. A variety of processing methods are required, such as turning, milling, planing, grinding, etc. Stamping, spinning, electrochemical processing, etc., thus requiring materials with good processing properties.

4) High thermal conductivity Due to some product development requirements, the development direction of vacuum electronic devices in recent years is high power and ultra-high frequency. At the same time, due to the miniaturization of the device, it brings great difficulties to the heat transmission of the device, which can easily cause damage to the device or premature end of its life. One of the solutions is to use materials with high thermal conductivity, such as BN, AlN and other high thermal conductivity materials. High-efficiency ceramic materials.

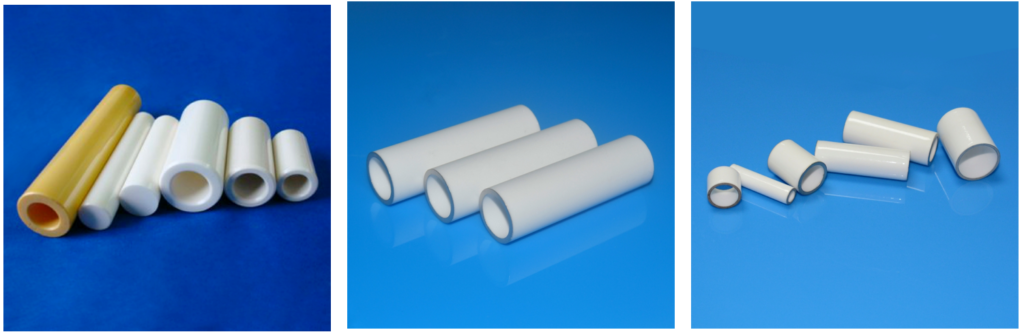

Electric vacuum ceramics are an important source of materials for vacuum electronic devices and are important dielectric materials in devices, including oxide ceramics, silicate ceramics, nitride ceramics, and special ceramics such as attenuation ceramics and machinable ceramics. Judging from the current usage and development, Al2O3 ceramics, BeO ceramics, BN ceramics, AlN ceramics and diamond ceramics are the most important.