Services for Alumina Ceramic Parts

You can get rich supports in alumina ceramic parts,our capabilities and services are as follows :

- Material:99.5% ,99%,96%,95%,94%,85%,75% alumina

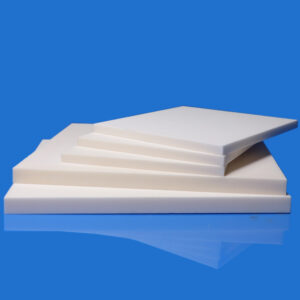

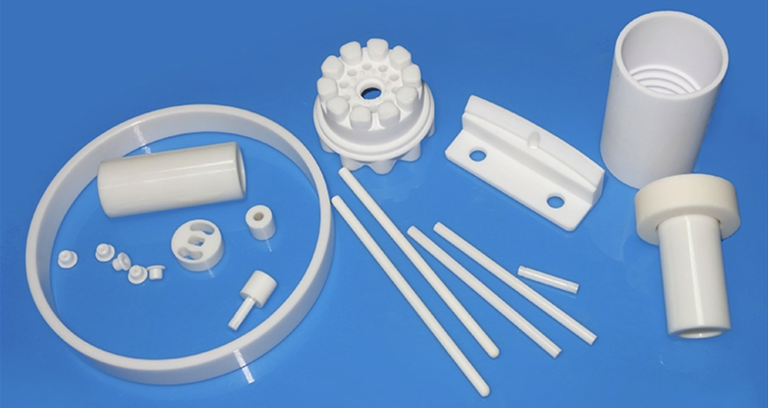

- Product type:rods, plates, tubes, discs, bushing or other shapes

- Production process: slurry method , dry pressing method

- Surface finishing: grinding, polishing, metallization

- Processing accuracy: dimensional accuracy can be controlled to 0.005mm

Different alumina percentages for your choose

Our alumina ceramic products, with alumina content from 75-99.9%, are available in different percentage compositions for you to choose from.

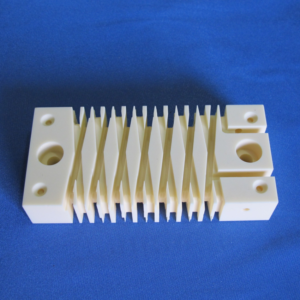

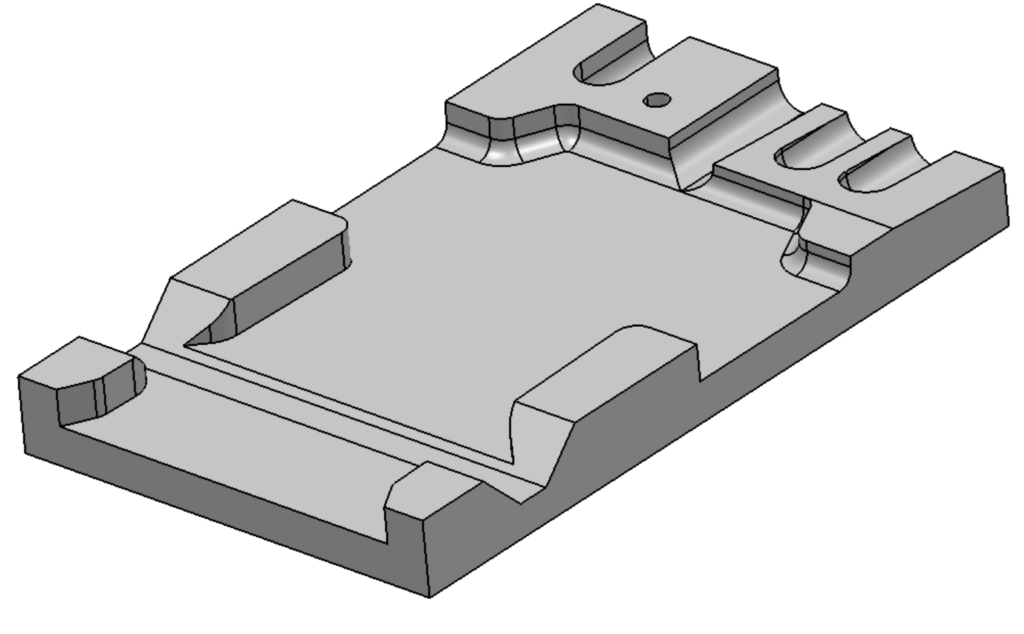

Provision of ODM services

Jinghui ceramic can provide ODM technical services, your research and development of new products, we can provide product design support with the experience for possible product pitfalls, also can provide updating data for product design optimization.

Rapid Proofing Service

For your R & D initial new products, we can provide rapid sampling services, and equipped with specialists for the whole process of follow-up and timely communication.

Main product features and applications

Alumina ceramics are the most used type of structural ceramics, and have many excellent properties.Jinghui Ceramics can provide different alumina ceramic parts in various shapes, such as ceramic plates, rods, tubes , substrates, bushings and so on.

Low coefficient of thermal expansion

suitable for use in high and low temperature working environment

Wear-resistant

suitable for mechanical seals.

Easy to combine with metal

fit for the local surface metallisation, brazing and metalization.

Excellent insulating properties

can be used as an insulating pipe or insulating board.