Services for Zirconia Ceramic Parts

You can get rich supports in zirconia ceramic parts of engineering ceramics,our capabilities and services are as follows :

- Material:mainly yttria partially stabilized zirconia (Y-PSZ), magnesia partially stabilized zirconia (Mg-PSZ)

- Product type:rods, plates, tubes, discs, bushing or other shapes

- Production process: slurry method , dry pressing method

- Surface finishing: grinding, polishing, metallization

- Processing accuracy: dimensional accuracy can be controlled to 0.002mm

Customized Parts Colors for You

Zirconia Ceramic Parts are normally white, yellow or gray, if you want other colors,we have a variety of stabilizers and colorants based on your requirements, for example, if you need blue, we will add vanadium-zirconium blue material, and if you prefer yellow, we can add magnesium oxide.

Product Classification and Processing Capability

Jinghui Ceramics can provide standard zirconia ceramic parts in various shapes, such as ceramic plates, rods, tubes , substrates, bushings and so on.

If you need to customize special shapes and have special requirements for dimensions, please contact us and give us a drawing to confirm, or you can use text to describe your needs and we will provide a drawing back to you for confirmation. We will be happy to provide you with technical analysis of the product and a competitive quotation.

Zirconia Ceramic Plungers

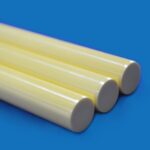

Zirconia Ceramic Tubes and Rods

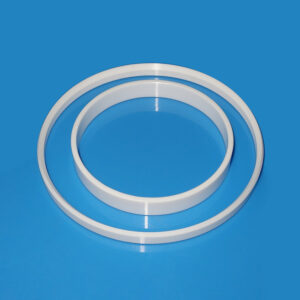

Zirconia Ceramic Ring

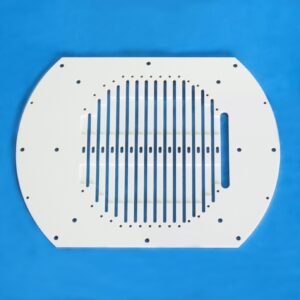

Ceramic Plates and Substrates

Sealing Ceramics

Zirconia Structural Parts

Main Characteristics of Zirconia Ceramic Parts

Zirconia ceramics are newly developed structural ceramics that are second only to alumina ceramics and have many excellent properties.

Superior Mechanical Strength

zirconia ceramic density is >5.85g/cm3 , called"ceramic steel" due to the high density. Its hardness is 1300 HV,more resistant to tear than many metals, its coefficient of thermal expansion is close to steel, (8.0~9.5) x 10-6/°C.

High Temperature Resistance

Zirconia ceramic has a high melting point of 2700 ℃ ,so its maximum operating temperature of 2200°C in atmospheric air.Zirconia fiber is currently the top international refractory fiber material.

Good Surface Finish

Zirconia ceramics have a good surface finish, both internal and external surfaces are easy to surface process, can achieve a mirror effect, and have excellent self-lubricating properties.

Low Thermal Conductivity

the thermal conductivity of zirconium oxide is (2~3) W/m.K, such a low thermal conductivity means good adiabatic performance, such as sprayed with zirconium oxide thermal barrier coating of the turbine, it can reduce the external heat degree of 50~200 ℃.

Good Chemical Stability

Acid and alkali corrosion resistance is much stronger than SiO2 and Al2O3, slightly soluble in HCl and HNO3; in the case of heating, dissolved in H2SiO4, can be reacted with HF, resistance to oxidation and aging.

Good Biocompatibility

It is biocompatible and can be used in medical and dental implants without causing an adverse reaction

High Insulation

High volume resistance makes zirconia products suitable for a wide range of high current and high voltage applications.

Other Properties

You may note some of the disadvantages of zirconia ceramics themselves:more expensive than some other ceramic materials;difficult to machine and fabricate; susceptible to chipping and cracking if not handled with care.

Timely Communication with You

Regardless of the number of orders, we will have a special person to follow up the entire order process and provide 24-hour online service to communicate with you.

The technical difficulties of the product and the focus of quality control, we will carry out timely technical analysis before production and communicate with you to confirm in a timely manner.

If you have quality issues related to the sold products, we will have someone to follow up with feedback and resolution.