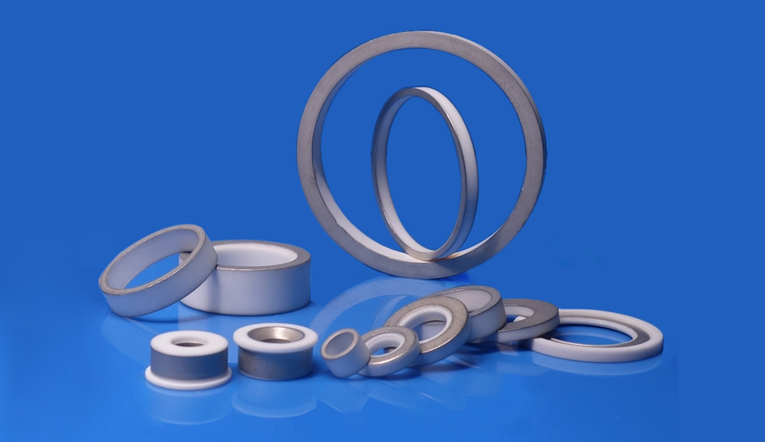

Customized Metallized Ceramics

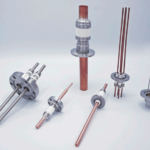

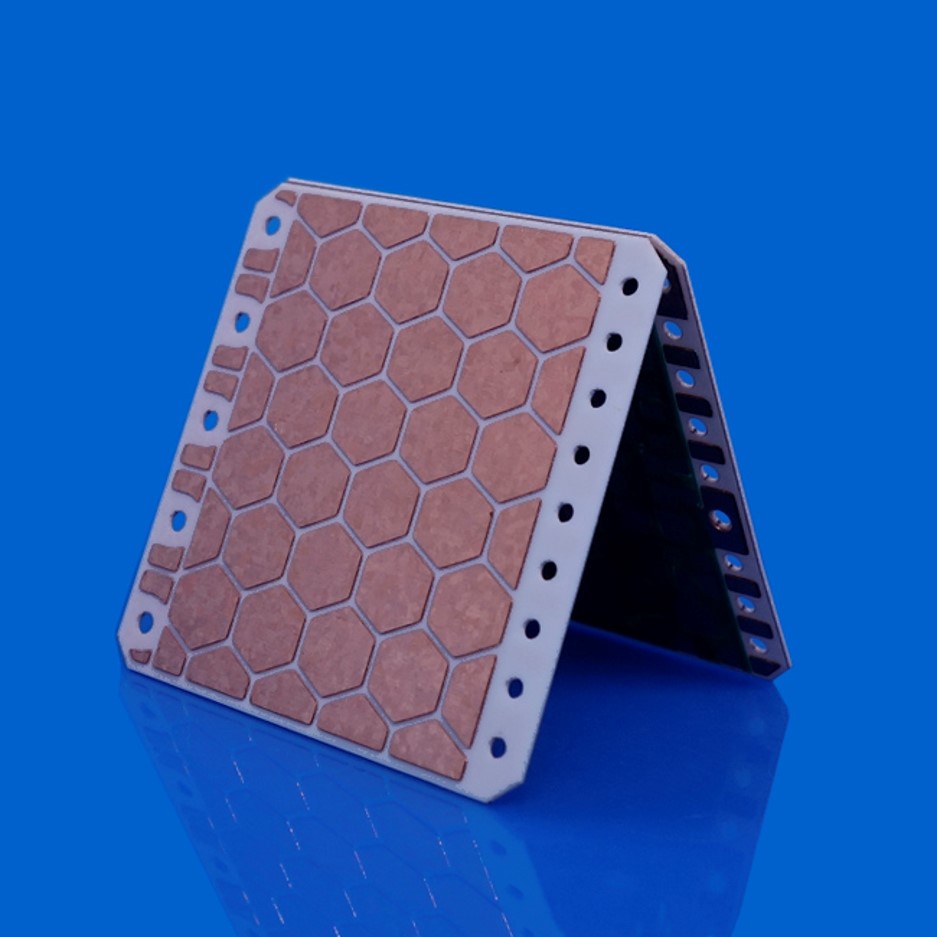

Jinghui manufactures a variety of precision metallized ceramics in high purity aluminum oxide and zirconium oxide for high vacuum, high voltage, high current and high pressure applications, mainly including vacuum electronics, medical, new energy vehicles,aerospace industries.

Metallized ceramic components play a critical roles in the ceramic-to-metal seal technology,the quality of metal film applied on ceramic surface is direct to the performance of the brazed assembly, as well as the reliability. All these are based on the premise because of our skillful, powerful and rigorous engineering & production team and on ours own cutting-edge & comprehesive equipments. Our metallized ceramic products will let you free of weak adhesion strength, poor air tightness issues, please trust you choice, let’s work together now!

Table of Contents for this Page

It is not easy to introduce all aspects of metallized ceramics, so we have prepared a lot of information on this page for you to delve into. To make sure you can find the information you want quickly, we have prepared this content directory that will jump to the corresponding location when you click on it.

the Typical Applications

After the surface of the ceramic component metallized, it owns both the characteristics of technical ceramics and some properties of metals, which broadens its application range. Metallized ceramic products are widely used in vacuum electronics, medical, new energy vehicles, chemical industry, aerospace and other fields.

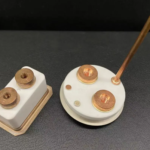

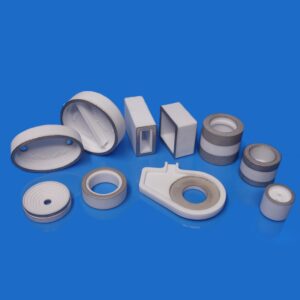

Hot Products Display

In order to help our customers to reach out their needs easily, the Metallized Ceramics by internal are classified into 3 types:

1) Metallized Ceramic Insulators

2) Metallized Ceramic Rings

3) Metallized Ceramic Tubes

You can find the products you need from our classification.

Wanna know about other ceramic metallization products?

Reference Cost Analysis

There are mainly 4 factors as shown below that affect your purchase cost, and you need to consider carefully before placing an order.

Purchase Price

Good things, not so expensive! Our products have a high cost performance, which can bring you more value and benefits.

Tariffs and Taxes

The cost is relatively fixed. Influencing factors include import customs code, national policies and agreements, the value of imported goods and types of imported goods.

Transportation Cost

Choose from express, air, truck, train or sea, the cost is different, and the shipping time is also different.

Quality Cost

This is a hidden cost that is easily overlooked and occurs when there are quality problems such as high non-conforming ratio, returns, replacements, and repairs.

Estimated Lead Time

1.How do we handle your order?

After we receive your customized product order, we will deal with it according to the following steps:

Step 1: Order confirmation

First, an internal contract review will be done. We will confirm your needs, including product specifications, quantity, unit price,delivery time, etc., to ensure that the order information is accurate.

Step 2: Production evaluation and plan

We will evaluate production capacity including raw material procurement, production equipment and production personnel arrangements, and then formulate a production plan, including production schedule, procurement plan, production process, etc., to ensure that production is carried out in an orderly manner.

Step 3: Process control and product inspection

During the production process, we will conduct quality control on raw materials, production equipment, and production personnel . After the production is completed, we will conduct strict inspection and testing on the product to ensure that the product meets the specifications and quality you require.

Step 4: Packaging and delivery

When the product passes the inspection, we will pack and ship it to ensure safe and complete delivery to you.

Step 5: After-sales service

After the product is delivered, we will establish a sound after-sales service system to respond and deal with your questions and needs in a timely manner to ensure customer satisfaction.

2. How long does it take from placing an order to receiving the goods?

Delivery time

- In stock: 2~3 working days

- Others: 4~6 weeks

Transportation time

- By express: 3-7 days

- By air: 7-15 days

- By truck: 15-20 days

- By train: 20-25 fays

- By sea: 30-35 days

Want to know how to compress lead times?

If you are not satisfied with the delivery time or need us to expedite the shipment, please contact our sales in time to communicate.

the Basic Knowledge

1. Ceramic metallization process

1.1 Process flow of ceramic metallization

The ceramic metallization is a process in which a metal layer is deposited onto the surface of engineering ceramics, with the purpose of offering a wettable surface for brazing to metal. The process flow includes three steps — surface treatment, metallization treatment and post-processing, and different methods need to be selected according to specific conditions.

Before metallization of ceramic products, the surface of ceramics needs to be cleaned, polished, pickled, etc. to ensure that the surface is clean, smooth and with appropriate roughness.

Metallization is the process of depositing a metal layer on the surface of ceramics. Commonly used metallization methods include electroless nickel plating, silver firing and Mo-Mn method.

After metallization, subsequent treatments are required to provide adhesion and corrosion resistance to the metal layer. The commonly used subsequent treatment methods include heat treatment and chemical treatment.

1.2 Metallization method of ceramics

At present, our commonly used metallization methods include electroless nickel plating, silver firing and Mo-Mn method. These processes are described one by one below.

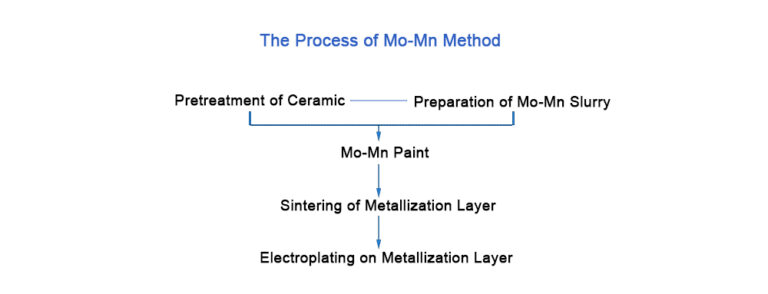

1.2.1 Mo-Mn method

The Mo-Mn method is to coat metal powders such as Mo powder and Mn powder on the ceramic surface, and then sinter at high temperature in a reducing atmosphere (hydrogen gas) to form a metal layer on the ceramic surface. Since Mo and ceramics have similar coefficients of thermal expansion, the thermal stress after bonding is small, so the bonding strength between the metal film and the ceramics is high.

1.2.2 Activated Mo-Mn method

It is an improvement on the basis of the traditional Mo-Mn method. The essence is to add some oxides that can form a glass phase during metallization to the Mo-Mn formula, such as Al2O3, SiO2, etc., to expand the adaptability of the original Mo-Mn formula. At present, the activated Mo-Mn method is mainly used in Al2O3 ceramics.

The disadvantage of the activated Mo-Mn method is that the process is complicated and the cost is high, but its combination is firm and can greatly improve the wettability, so it is still a widely used process in the ceramic-metal sealing process.

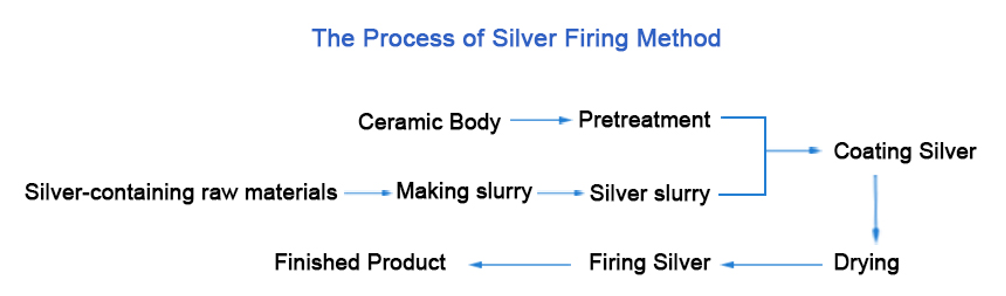

1.2.3 Silver firing method

The silver firing method is the earliest and most mature method of ceramic metallization. Silver is highly conductive and has good oxidation resistance. The coefficient of thermal expansion of silver is close to that of ceramic materials, and it is easy to form a firm bond with good thermal stability. The process flow of the silver firing method is to pretreat the ceramics first, and then apply the prepared silver-containing slurry on the surface of the ceramics. After drying, the silver slurry is fired into a silver film and fixed on the ceramic surface.

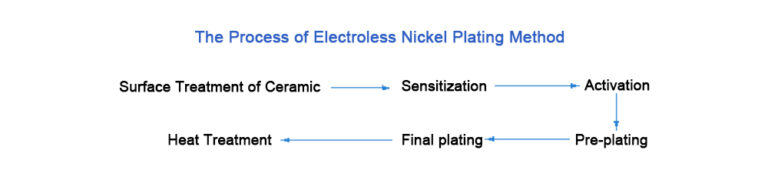

1.2.4 Electroless nickel plating method

Electroless nickel plating is also called chemical nickel plating or autocatalytic nickel plating. It is a metal deposition process carried out by autocatalytic reduction of nickel ions on the ceramic surface through an appropriate reducing agent in the solution without an external current. The bonding strength of the metal layer obtained by electroless nickel plating depends largely on the roughness of the ceramic surface. Within a certain range, the greater the roughness of the ceramic surface, the higher the bonding strength.

1.3 Thickness of metal layer

There are four types of ceramic metallization that we commonly use.

① On the ceramic surface: first sintered into a Mo-Mn layer – then Ni plating.

② On the ceramic surface: first sintered into a Mo-Mn layer – then Ni plating – and then Au or Ag plating.

③ On the ceramic surface: direct printing and sintering into a Ag layer, which is often called silver coating.

④ On the ceramic surface: first sintered into a W layer – then Ni plating – and then Au or Ag plating.

The thickness of the metal layer obtained by different metallization methods are listed in the table below.

| Category | Type of Metallization | Film Thickness | Middle Layer | Film Thickness | Coating | Film Thickness |

|---|---|---|---|---|---|---|

| Al2O3/ZrO2 Ceramic Body | Mo-Mn only | Norminal: 15-40 μm | ||||

| Al2O3 Ceramic Body | Ag | Norminal: 10-20 μm | ||||

| Al2O3/ZrO2 Ceramic Body | Mo-Mn | Norminal: 15-40 μm | Ni | Norminal: 2-6 μm | ||

| Al2O3/ZrO2 Ceramic Body | W | Norminal: 15-30 μm | Ni | Norminal: 2-6 μm | Au | Norminal: 0.02 μm |

2. Production capabilities of metallized ceramic products

- Available Raw Materials:

96% alumina (Al2O3), 99% alumina (Al2O3), zirconia (ZrO2), aluminum nitride (AlN)

- Available Secondary Processes:

Flat grinding, internal & external grinding, CNC machining

- Surface Treatments:

Metallizing, polishing, glazing

- Dimensional & Accuracy Capabilities:

| Dimensions | Max. OD | 300 mm | Min. OD | 1 mm | Max. Length | 500 mm |

|---|---|---|---|---|---|---|

| Axial | Roundness: 0.005 mm; Concentricity: 0.05 mm; Roughness: Ra 0.1 | |||||

| Hole | Min. diameter: 0.2 mm; Max. depth: 6 mm (Depends on the raw materials) | |||||

| Groove | Min. width: 0.10 mm; capable of processing various shapes | |||||

| Plane | Min. thickness: 0.10 mm; Flatness: 0.005mm; Measurable tolerance: 0.001 mm | |||||

| Screw | Min. thread: M2 | |||||

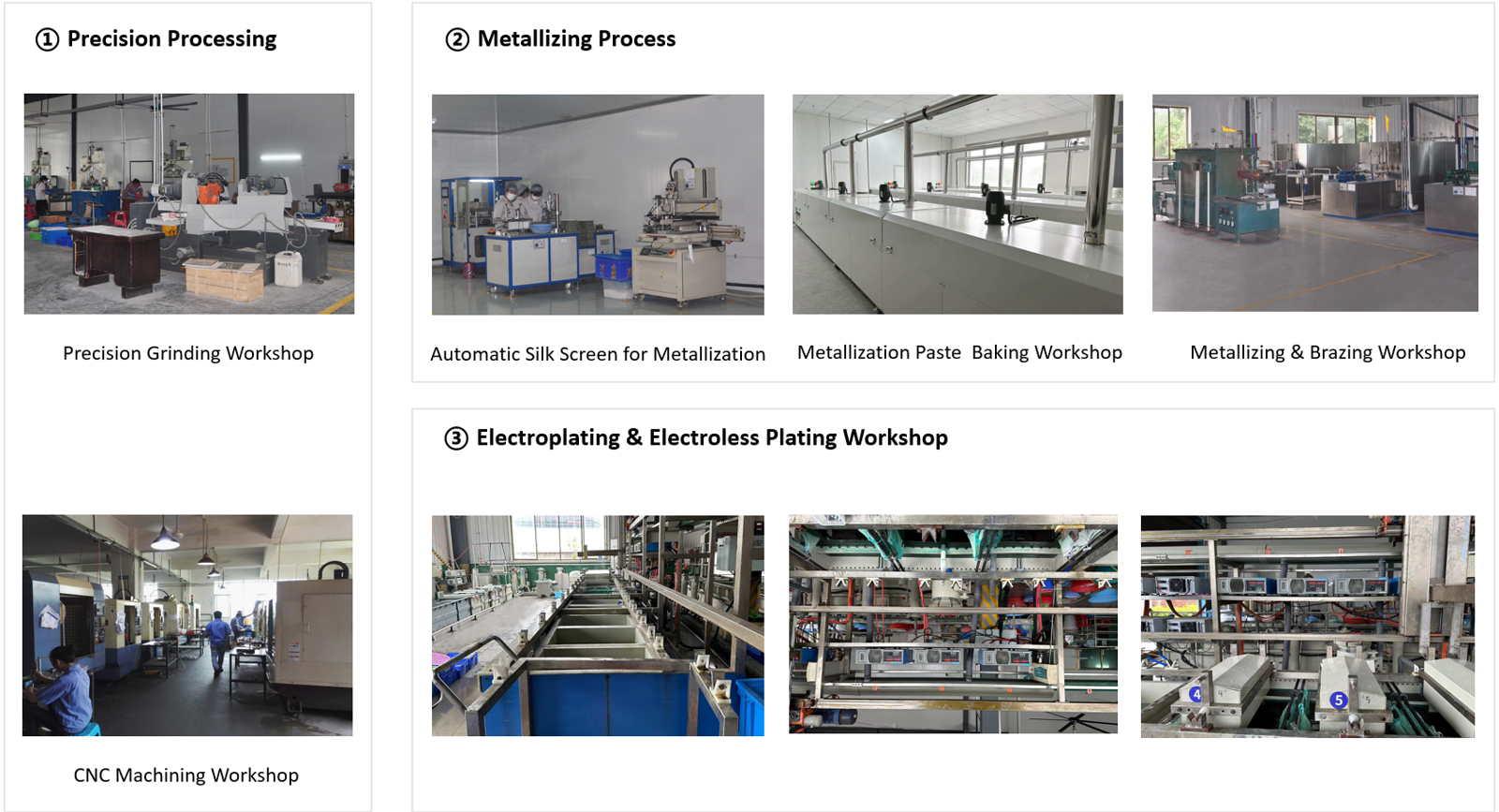

3. Manufacturing equipment

4 Quality assurance

4.1 Quality control policy

As an ISO9001 enterprise, the conduct code of all manufacturing activies, all departments are strictly based on procedure documents of quality management system.

4.2 Product quality standards

Our company strictly controls and manages all links related to product quality, establishes scientific inspection procedures, and quantifies the inspection indicators. The responsibility is assigned to everyone to ensure that the company continues to produce qualified products stably.

| No. | Category | Test Items | Testing Standard (GB/T 5593-1996 ...) | Inspection Tool |

|---|---|---|---|---|

| 1 | Dimensions and Tolerances of Ceramics | Dimensions and Tolerances | According to the specification. | Vernier Caliper; Coating Thickness Gauge; Micrometer; Height Gauge, Surface Roughness Meter and CMM |

| Unmarked Dimensions and Tolerances | Negotiate with customers and reach consensus. | |||

| 2 | Appearance and Surface Defects of Ceramics | Non-sealing Surface | Pits, air bubbles, open pores, etc. are not allowed on the non-sealing surface, or the size and quantity shall not exceed those specified in the contract. | Visual; Optical Microscope |

| 3 | Cosmetic Quality of Metallization Layers | Appearance of Metallization Layers | The metallization layer should be dense, uniform, continuous and flat. | Visual; Optical Microscope |

| 4 | Performance of the Sealing Surface | Tensile Strength | Get several tensile test data and calculate the final test result. | Tension Testing Machine; High Precision Vernier Caliper; Fixture |

| Air Tightness | Sealing performance | Helium Leak Detector | ||

| Reliability | Thermal Cycle Performance | Temperature Change Test |

the Future Trends

- Process Improvement

The optimization of technological process, the reduction of production energy consumption and production cost, and the realization of large-scale production of products are still to be explored.

- Direction of Product Development

High power, high frequency electronic devices are the main direction of future development, so the development of better performance and higher quality sealing devices still need to be focused on.

- Academic Research Focus

At present, academia studies mostly on physical properties, organizational structure and new technology, but less on metallization mechanism. The study of metallization mechanism is the basis for improving the level of metallization and all other research. Therefore, the research on the metallization mechanism will surely become the focus of attention in the future.

Why Choose Us

As a manufacturer of metallized ceramic products, we have the following advantages:

01-Reliable production and well-controlled cost

In-house comprehensive manufacturing equipment from raw material formulating, sintering, secondary processes, metallizing and electroplating.

02-Superb quality products

Optimized production process and scientific manufacturing flow chart, especially rigorous quality-control methods and sense

03-Professional production and engineering team

All of them are more than 10+ years experience, assist related teams to find the solutions more efficiently.

04-Strong production capability

Selection of shaping methods for small-size to large-size and precision machining machines with abundant production capacity.

05-Free Technical consultation and free design

Offering technical consultation and design proposal free of charge, especially at prototyping phase.

06-Continuous innovation ability

We continue to innovate, develop higher-quality metallized ceramic products, and constantly update and improve the production process to meet the changing needs of customers.

FAQs

The FAQs (Frequently Asked Questions) column is designed to provide users with fast and convenient answering services. We hope that through the FAQs column, we can help you better understand our products and services. If you have any suggestions or comments on the FAQs column, please feel free to contact us.

(1) Product specifications and requirements: In order to customize metallized ceramic products, it is very important to provide detailed drawings or product descriptions. Drawings are generally in PDF format. If the product structure is complex, it is best to provide 3D drawings in "STEP" file format. If there is no detailed drawing, you should provide as detailed a product description and reference materials as possible (such as product samples or reference drawings) to help us better understand your product needs.

(2) Quantity and delivery time: They usually have an impact on the quotation. Generally speaking, the price of large quantity order is more favorable; the price of an urgent order is higher. You can communicate with us and negotiate the best price and delivery time.

After accurately understanding your needs, we will provide you with quotations and customized solutions within 24 hours.

Samples of standard sizes are free, and we only charge for shipping. If customization is required, we only collect sample fee for MOQ.

Our company has been focusing on quality and service. If the product quality does not meet the contract requirements, our company will immediately arrange to re-produce qualified products; if we cannot provide qualified products, we will arrange refunds.

All of our products are packed in safe packages suitable for long-distance transportation, which are not easy to be damaged; in case of damage, please cooperate with our company and logistics company to go to claim process at the first moment, and then our company will arrange replenishment.

After 15 years of development, our company has formed four advantageous product chains, which are metallized ceramic products, ceramic grinding burrs, ceramic substrates and engineering ceramics. In addition, we can also supply ceramic plates, ceramic tubes, thermostat ceramics, ceramic seals, textile ceramics, spark plug insulators, honeycomb ceramics, etc. All of our products can be customized, and we provide proofing and mass production services.