Services for Metallized Ceramic Insulator

You can get rich supports in metallized ceramic insulator,our capabilities and services are as follows :

- Material:mainly alumina ceramic , such as 95% alumuna,96% alumina,99% alumina

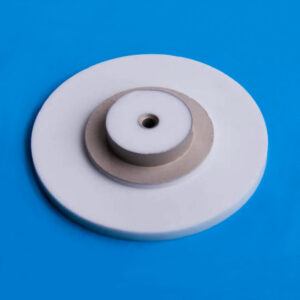

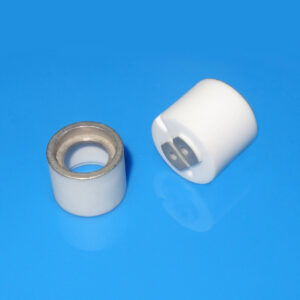

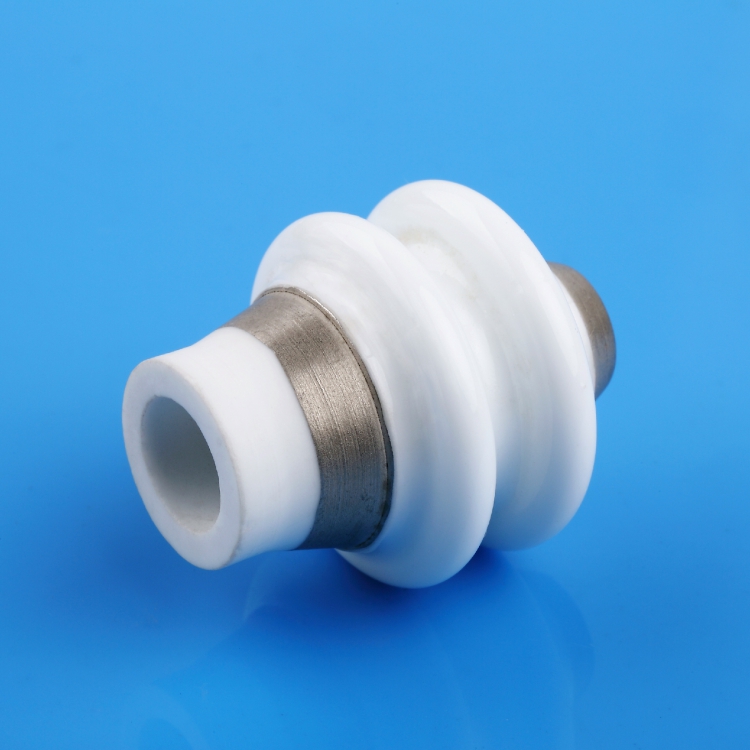

- Product type:rods, plates, tubes, discs, bushing or other shapes

- Production process: dry pressed,hot pressed,isostatic pressed,extrusion

- Metallization type: body+Mo/Mn,body+Mo/Mn+Ni,body+Ag,body+W+Au

- Metallization layer adhesion:>120 Mpa

How to Choose the Metallization Layer

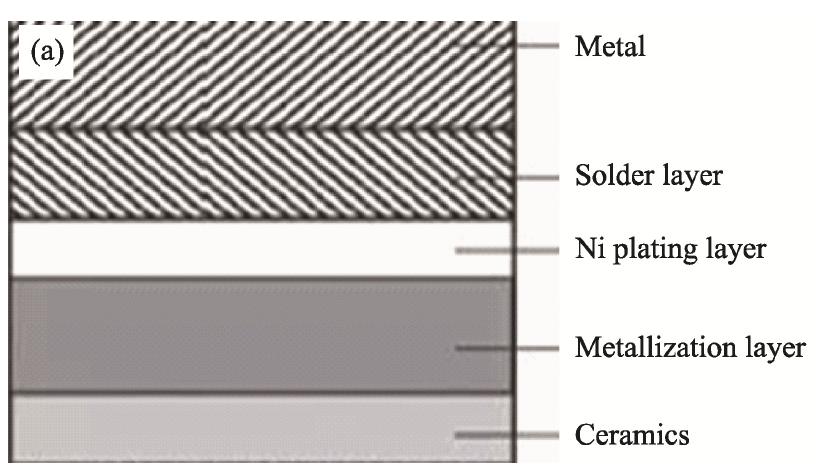

When the surface metallization of ceramics is applied to ceramic-metal sealing, in order to obtain a dense and firm bond, first of all, there should be good wetting between the sealing agent and the metal and ceramics, and there should be a certain chemical reaction mechanism in the meantime, which can form a continuous, chemically combined transitional tissue layer. It is neither purely physical adsorption, nor will it lose its respective functions due to excessive erosion. Second, the coefficients of thermal expansion of ceramics and metals bonded to each other should be as close as possible. The commonly used metallization method is to first make a transition metal layer (Mo,Ti, etc.) on the ceramic, and then plate a highly conductive metal layer (Ag, Au, Ni, Cu, etc.).

Types and Applications of Metal Layers

Metallized ceramic products are covered with different metal layers, and different metal layers have different functions and usage scenarios.

Al Layer

Shading, UV protection.

Ti Layer

Wear and corrosion resistance; firmly bonded to ceramics.

Pt Layer

Wear, heat and corrosion resistance; good electrical conductivity; strong absorption capacity for gases (especially H2, O2 and CO).

W Layer

Wear, corrosion and high temperature resistance; a new environmentally friendly process to replace Cr plating (low replacement cost).

Mo Layer

Wear, corrosion and high temperature resistance.

Ni Layer

It is biocoWear and corrosion resistance; enhance welding abilitympatible and can be used in medical and dental implants without causing an adverse reaction.

Ag Layer

Improve conductive contact resistance, enhance signal transmission; enhance welding ability.

Au Layer

Improve conductive contact resistance, enhance signal transmission; enhance welding ability.

Cu Layer

Improve conductive contact resistance, enhance signal transmission; enhance welding ability.

Cr Layer

Very good wear resistance (lowest coefficient of friction among metals), corrosion and high temperature resistance; enhance welding ability.

Zn Layer

Excellent anti-atmospheric corrosion and anti-electromagnetic field performance; relatively low cost.

Sn Layer

Corrosion and high temperature resistance; enhance welding ability.

Coefficients of Thermal Expansion of Common Metals

Coefficient of thermal expansion for alumina is 5.0~8.0 *10-6/℃, CTE of common metals ia as follow:

| Metal | 1×10-6/℃,20-800℃ | Metal | 1×10-6/℃,20-800℃ |

|---|---|---|---|

| Al | 23.2 | Ag | 19.5 |

| Ti | 10.8 | Au | 14.2 |

| Pt | 9.0 | Cu | 17.5 |

| W | 4.5 | Cr | 6.2 |

| Mo | 5.2 | Zn | 36.0 |

| Ni | 13.0 | Sn | 2.0 |