Introduction to Standoff Insulators

Standoff insulators are precision insulating ceramics. The role of insulating materials in electrical or electronic circuits is mainly to physically isolate conductors according to circuit design requirements, preventing current from flowing between them and disrupting the normal operation of the circuit. That is to say, in electronic technology, the insulating material is firstly required to be non-conductive, that is, the resistivity is required to be as high as possible, and the insulation strength is also required to be as high as possible. In addition, the insulating material also plays the role of mechanical support of the conductor, heat dissipation and circuit environmental protection.

High-voltage ceramic insulators have a history of more than 100 years as a traditional insulating ceramic. Compared with high-voltage ceramic insulators, precision insulating ceramics are a rising star, and their role in modern electronic technology is unmatched by the former. For example, in many household appliances, in general integrated circuits (IC), large-scale integrated circuits (LSI) and very large-scale integrated circuits (VLSI), in high-tech products such as large electronic computers, and even in cutting-edge technology fields such as aerospace, standoff insulators have been widely used.

Material Selection of Standoff Insulators

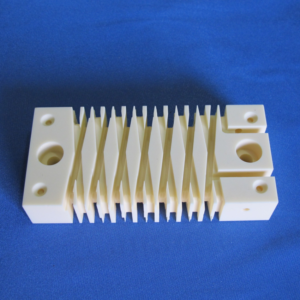

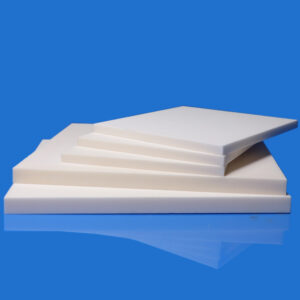

Standoff insulators are more often made of 95% alumina (Al2O3) ceramics. This ceramic material has excellent insulation performance, high temperature stability and chemical stability, so it is widely used in insulation and packaging materials in the fields of electronics, electric power, aerospace and other fields.

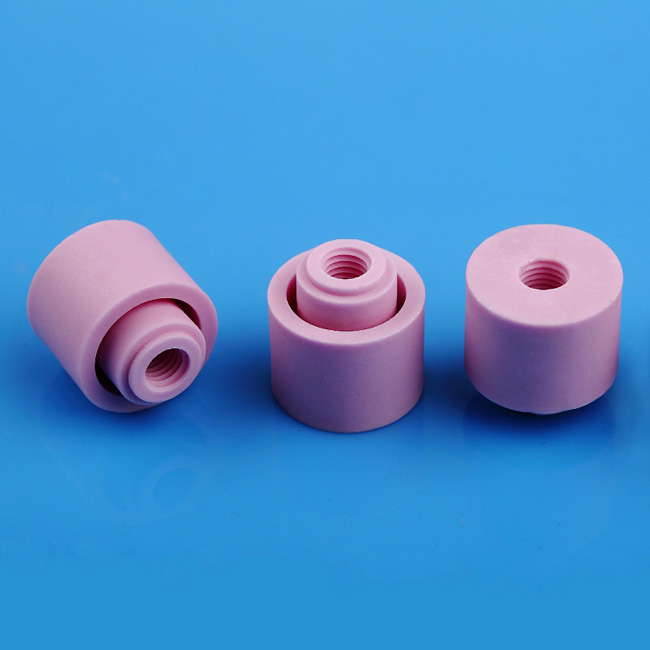

Standoff insulators can be made into different colors according to specific needs, such as pink due to the addition of specific pigments or colorants. The properties and stability of the ceramic material need to be considered when choosing a color to ensure that the color does not negatively impact the insulating and other critical properties of the material. In addition to the common white and pink, they can also be made into other colors, such as black, gray, yellow, green and so on.

The choice of different colors is usually based on the following considerations:

1. Aesthetic requirements: According to the overall design of the product or equipment and market demand, select the appropriate color to improve the attractiveness and aesthetics of the product.

2. Identification: Different colors can be used to identify products. For example, in electronic equipment, ceramic components of different colors can be used to distinguish different functions or connections.

3. Visibility and contrast: Some colors have better visibility and contrast in specific environments, for example, in a dark environment, choosing bright colors can improve visibility.

4. Brand and market positioning: Some companies or brands have their own standard colors. By choosing specific colors, they can match the brand image and market positioning.

Our Advantages

Jinghui has accumulated more than 15 years of experience in the field of advanced ceramic products, and can produce various specifications according to customers' drawings, with superior performance. Our customers appreciate our product quality very much.