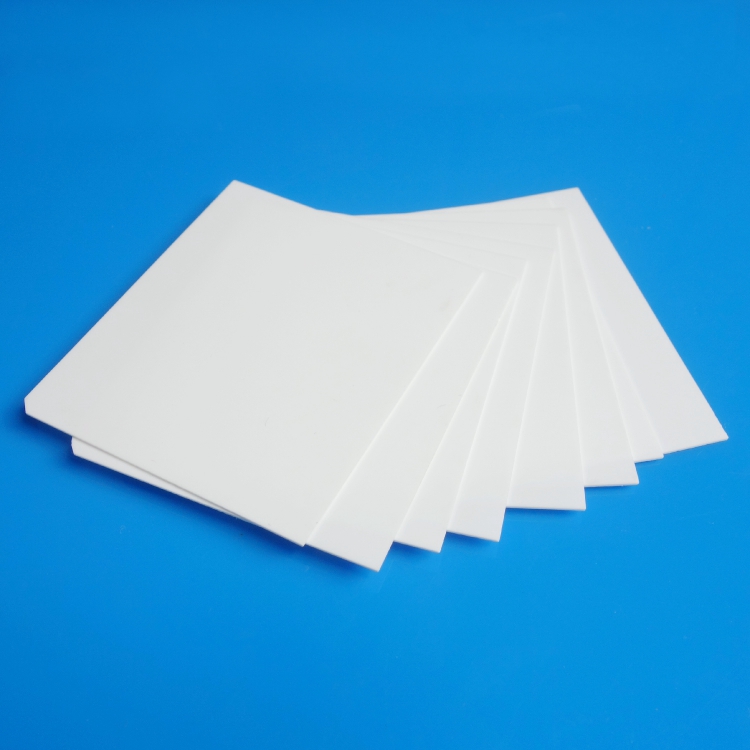

Product Introduction

96% alumina ceramic substrate is a common high-purity alumina ceramic substrate with an alumina content of over 96%. Alumina ceramic substrates have excellent physical and chemical properties, so they are widely used in the fields of electronics, communications, optoelectronics, and electric power.

96% alumina ceramic substrate has the following characteristics:

1. High temperature stability: It can maintain stable performance under high temperature environment.

2. High mechanical strength: able to withstand certain external forces and stresses.

3. Good insulation performance: it can be used as the insulating layer of electronic components.

4. Strong corrosion resistance: it can be used stably for a long time in harsh environments.

5. Good dimensional stability: not easy to deform, can meet the requirements of precision assembly.

6. Excellent thermal conductivity: it can be used for heat dissipation of high-power electronic components.

Material Properties

| Alumina Ceramic Substrate |

| Item |

Unit |

96% Al2O3 |

| Mechanical Properties |

| Color |

/ |

/ |

White |

| Density |

Drainage Method |

g/cm3 |

≥3.70 |

| Light Reflectivity |

400nm/1mm |

% |

94 |

| Flexural Strength |

Three Point Bending |

MPa |

>350 |

| Fracture Toughness |

Indentation Method |

MPa·m1/2 |

3.0 |

| Vickers Hardness |

Load 4.9N |

GPa |

14 |

| Young’s Modulus |

Stretching Method |

GPa |

340 |

| Water Absorption |

|

% |

0 |

| Camber |

/ |

Length‰ |

T≤0.3: ≤5‰, Others: ≤3‰ |

| Thermal Properties |

| Max. Service Temperature (Non-loading) |

/ |

℃ |

1200 |

| CTE (Coefficient ofThermal Expansion) |

20-800℃ |

1×10-6/℃ |

7.8 |

| Thermal Conductivity |

25℃ |

W/m·K |

>24 |

| Thermal Shock Resistance |

800℃ |

≥10 Times |

No Crack |

| Specific Heat |

25℃ |

J/kg·k |

750 |

| Electrical Properties |

| Dielectric Constant |

25℃, 1MHz |

/ |

9.4 |

| Dielectric Loss Angle |

25℃, 1MHz |

×10-4 |

≤3 |

| Volume Resistivity |

25℃ |

Ω·cm |

≥1014 |

| Dielectric Strength |

DC |

KV/mm |

≥15 |

Product Specification

|

96% Al2O3 Ceramic Substrate

|

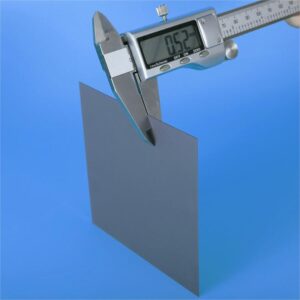

| Thickness(mm) |

Maximum Size(mm) |

Shape |

Molding Technique |

| As Fired |

Lapped |

Polished |

Rectangular |

Square |

Round |

| 0.25 |

120 |

114.3 |

114.3 |

|

√ |

|

Tape Casting |

| 0.3 |

120 |

114.3 |

114.3 |

|

√ |

|

Tape Casting |

| 0.38 |

140×190 |

|

|

√ |

|

|

Tape Casting |

| 0.5 |

140×190 |

|

|

√ |

|

|

Tape Casting |

| 0.635 |

140×190 |

|

|

√ |

|

|

Tape Casting |

| 0.76 |

130×140 |

|

|

√ |

|

|

Tape Casting |

| 0.8 |

130×140 |

|

|

√ |

|

|

Tape Casting |

| 0.89 |

130×140 |

|

|

√ |

|

|

Tape Casting |

| 1 |

280×240 |

|

|

√ |

|

|

Tape Casting |

| 1.5 |

165×210 |

|

|

√ |

|

|

Tape Casting |

| Other special thicknesses within the thickness range of 0.1-1.5mm can be achieved by lapping. |

Remark:

We not only produce ordinary square and rectangular ceramic substrates, but also round thin ceramic wafers, pink and black ceramic substrates. In addition, we produce aluminum nitride and silicon nitride ceramic substrates.

Typical Applications

96% alumina ceramic substrates are widely used in the packaging of electronic devices, the insulating layer of circuit boards, high-power LED heat sinks, optoelectronic devices, power electronic devices and other fields. Its high temperature stability, high mechanical strength, and good insulation properties make it an ideal material of choice.