Introduction of Alumina DBC Substrates

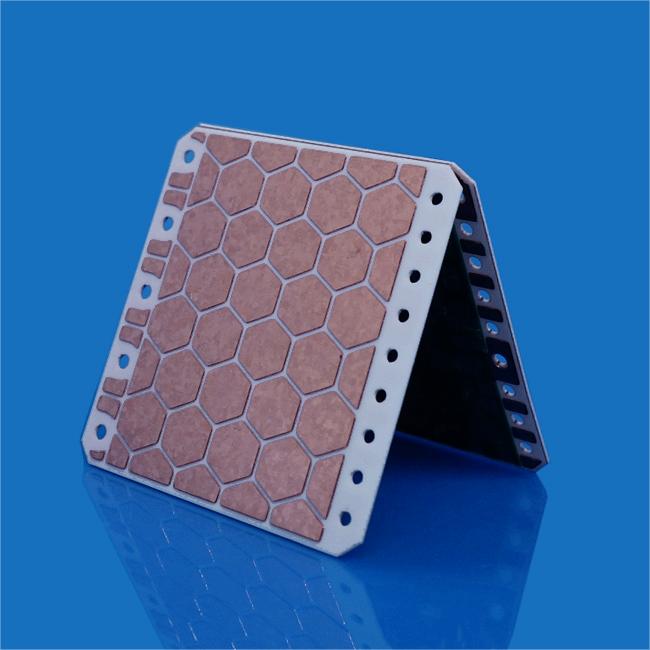

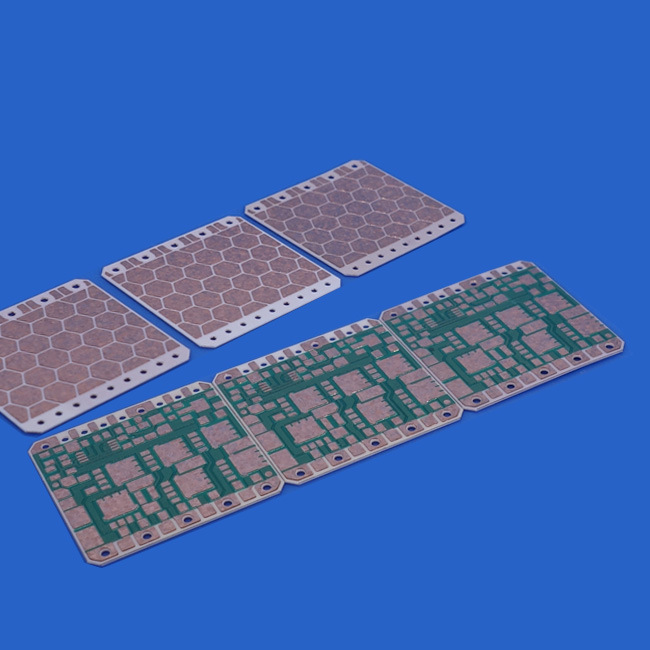

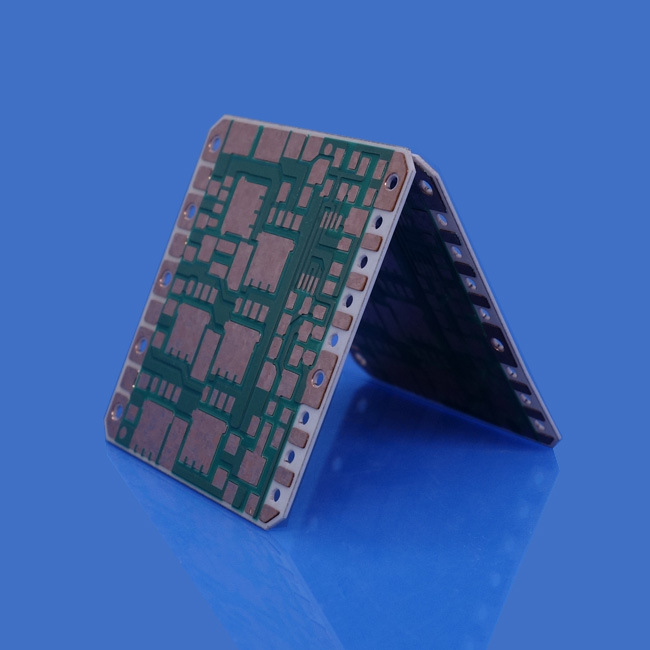

Alumina DBC substrate (Direct Bonding Copper, also known as Direct Bonded Copper or Direct Bond Copper) is a commonly used high-power electronic heat dissipation substrate. It consists of alumina ceramic substrate and copper clad layers. Ceramic CCL has the characteristics of high thermal conductivity, high electrical insulation, high mechanical strength, low expansion, etc., as well as high conductivity and excellent soldering performance of oxygen-free copper, and can etch various patterns like PCB circuit boards.

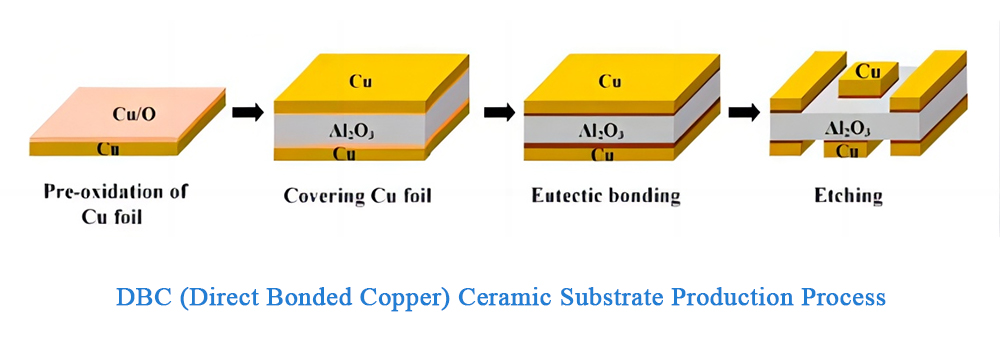

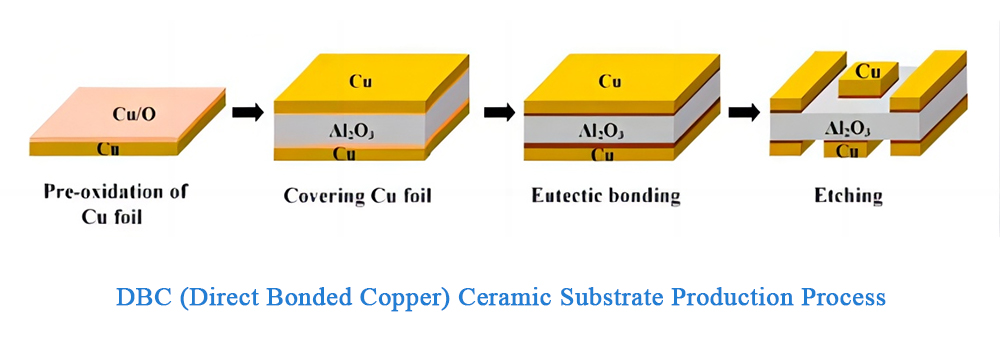

Production Process of Alumina DBC Substrates

The main feature of Direct Bonded Copper (DBC) technology is that the direct connection between copper foil and Al2O3 ceramics can be realized without adding other substances during the metallization process. The process is as follows:

First, cover the treated copper foil on the surface of Al2O3 ceramics, introduce an inert gas with a certain amount of oxygen, and then heat up. During this process, the copper surface will be oxidized.

When the temperature reaches the existence range of the eutectic liquid phase, Al2O3 ceramics and copper will form a eutectic liquid phase between each other, and the liquid phase will wet Al2O3 ceramics and copper at the same time to complete the initial connection, and then in the cooling process, the eutectic liquid phase precipitates Cu and Cu2O, which exist at the connection interface to achieve a tight connection.

Product Application

Alumina DBC substrates are widely used in the field of heat dissipation of high-power electronic devices. The following are some typical application scenarios:

1. Power semiconductor devices:

Alumina DBC substrates are often used in the heat dissipation structure of power semiconductor devices, such as IGBT (insulated gate bipolar transistor), MOSFET (metal oxide semiconductor field effect transistor), etc. These devices generate a lot of heat during operation, and the use of alumina DBC substrates can effectively conduct heat to the substrate surface, improving the heat dissipation efficiency of the devices.

2. Motor drivers:

Alumina DBC substrates are also widely used in the heat dissipation structure of motor drivers, such as motor controllers for electric vehicles, drivers for industrial motors, etc. These motor drivers will generate a lot of heat when they work under high load. Using alumina DBC substrate can effectively reduce the temperature and improve the working efficiency and life of the motor.

3. LED lighting:

Alumina DBC substrate is also suitable for LED lighting. The LED chip will generate a certain amount of heat when it is working, and the use of alumina DBC substrate can quickly conduct the heat to the heat sink, improving the brightness and life of LED lighting.

Our Advantages

Jinghui is a manufacturer of proofing and production of ceramic circuit boards. We have more than ten years of experience in circuit board production. We can process precision circuits, especially good at DBC technology, silver firing technology, electroless nickel plating technology and Mo-Mn technology. You can consult Jinghui for more processing methods of ceramic substrates.