Alumina Metallized Ceramics for Electrical Components

Why do Metallization on the Surface of Ceramic Structural Parts?

Ceramic metallization is the combination of two materials with different properties. The ceramic material has the characteristics of high strength, high hardness, high temperature resistance, corrosion resistance, and good insulation performance, while the metal material has the characteristics of good thermal conductivity, strong electrical conductivity, and good ductility.

The combination of ceramic and metal materials not only achieves complementary advantages in performance, but also broadens their respective application ranges.

Our product production is mainly divided into 3 steps, forming - finishing - metallization. The production flow chart is shown below.

| Forming |

Finishing |

Metallization |

| We will choose the most suitable forming method on the basis of saving costs and ensuring quality. |

In order to achieve the precision of the product, most ceramic structural parts need further finishing treatment after the sintering process. |

Metallization of ceramics refers to the creation of thin metal layers (films) on the surface of ceramics. After the surface of the ceramic material is metallized, it has both the characteristics of ceramics and the properties of metal. |

Which Metallization Processes We Support?

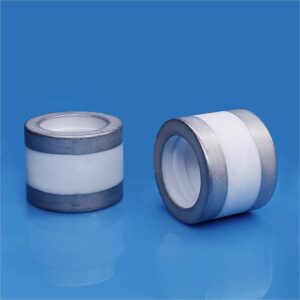

Jinghui has been focusing on the production and processing of precision ceramic structural parts for more than ten years. Our metallization options include Ag, Mo-Mn and W, etc., and the surface coatings include Au, Ni, Al, Ti, Cu, Cr, etc.

Our products are widely used in optical communications, medical, lighting, machinery, aviation, aerospace, petroleum, chemical, textile, consumer electronics, electrical appliances, smart wear and other fields.

Introduction to Electroless Nickel Plating Method

Electroless nickel plating (also known as chemical nickel plating or autocatalytic nickel plating) is a deposition process in which metals are produced through controllable redox reactions under the catalysis of metals.

The following is the general process of the electroless nickel plating method applied to the surface of the ceramic structural parts.

Advantages of Electroless Nickel Plating Method

Compared with electroplating nickel, electroless nickel plating has the characteristics of uniform coating, small pinholes, no need for DC power supply equipment, deposition on non-conductors and some special properties.

In addition, due to less waste discharge, less environmental pollution and lower cost, electroless nickel plating technology has gradually replaced electroplating nickel in many fields and has become an environmentally friendly surface treatment process.