Introduction of DCB Direct Copper Bonded Substrates

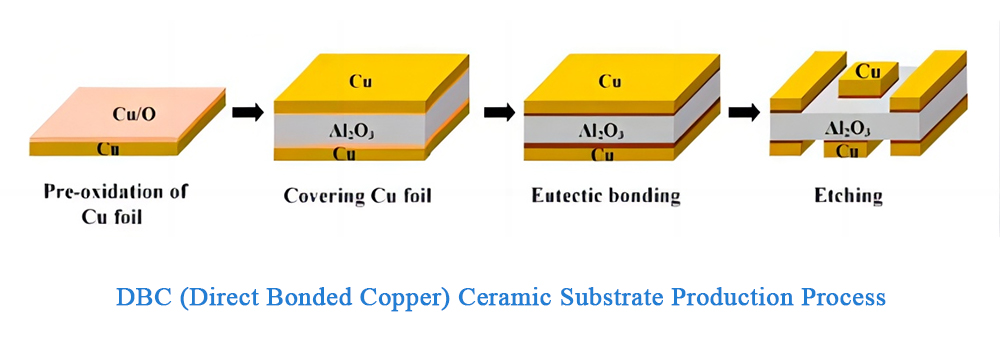

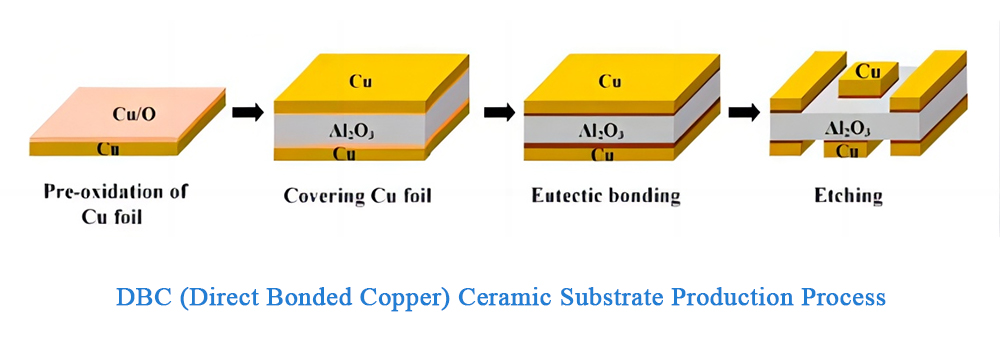

DBC (Direct Bond Copper) is also abbreviated as DCB (Direct Copper Bond) in literature, and the two have the same meaning. DBC is a ceramic surface metallization technology, which consists of 3 layers, with a ceramic insulating layer in the middle and a copper clad layer on the top and bottom. To put it simply, a layer of copper is covered on both sides of an insulating material, and then a pattern that can carry current is etched on the copper clad layer.

Direct Copper Bond ceramic substrate has the following characteristics:

●Strong mechanical stress, stable shape;

●High strength, high thermal conductivity, high insulation;

●Strong binding force, anti-corrosion;

●Excellent thermal cycle performance, cycle times up to 50,000 times, high reliability;

●It can etch various graphics like PCB board;

●No pollution, no pollution;

● Wide operating temperature: -55℃~850℃;

● The coefficient of thermal expansion is close to that of silicon, which simplifies the production process of power modules.

Comparison of DBC Substrate and PCB

The main function of the DBC needs to ensure the electrical insulation capability and good thermal conductivity between the silicon chip and the heat dissipation substrate, and at the same time meet a certain current transmission capability. The DBC substrate is similar to a 2-layer PCB circuit board. The insulating material in the middle of the PCB is generally FR4, while the commonly used ceramic insulating materials for DBC are aluminum oxide (Al2O3) and aluminum nitride (AlN).

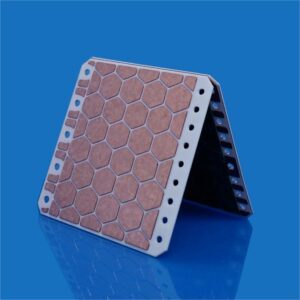

Product Packaging

Vacuum packaging is very important for DCB direct copper bonded substrates to prevent oxidation, keep clean, prevent moisture intrusion and static electricity protection. Through vacuum packaging, the quality and reliability of the substrate can be improved to ensure that it is not damaged and affected during transportation and storage.

Why Choose Us

DBC ceramic substrates are widely used in the packaging and heat dissipation of Insulated Gate Bipolar Transistor (IGBT), Laser Diode (LD) and Concentrator Photovoltaics (CPV). Jinghui strictly controls the eutectic temperature and oxygen content in the process of producing DBC ceramic substrates. The DBC technology has reached the industry-leading level and is worthy of your trust.