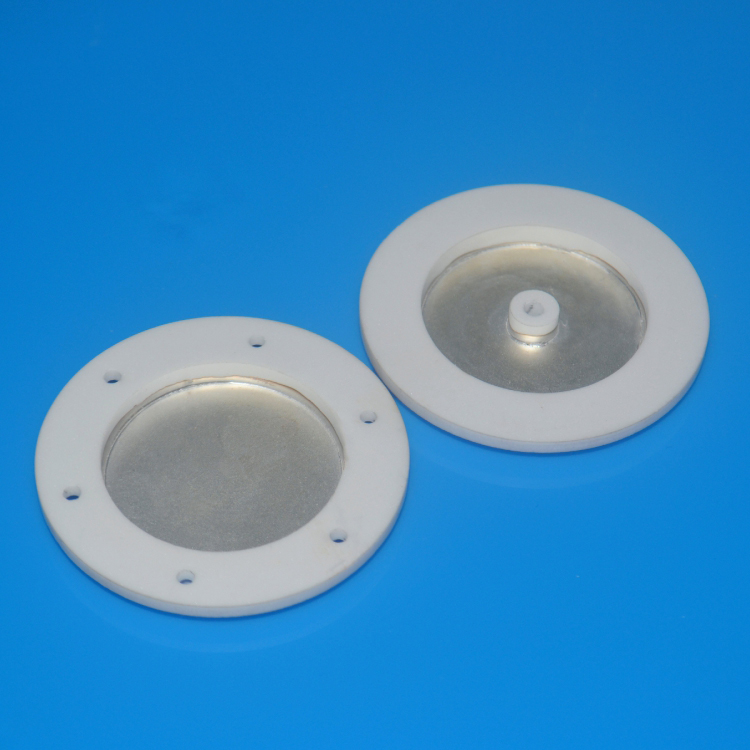

Description of metallized ceramic insulator

High alumina (Al2O3) offer exordinary electrical insulating properties, especially glazed al2o3 ceramic parts would withstand over 110 kilovoltes. Thus, alumina ceramic is a preferred advanced ceramic material to making high voltage ceramic insulator. With the dynamically development of technology in the electrical & electronics industry, the demand for ceramic to metal joining constantly increase, but the problem is what it's very difficulting in bonding ceramic to metal directly because of significant thermal expansion coefficient and less wettability between 2 materials, then the ceramic metallization technology was born.

Depositing a metal layer, such as Molybdenum (Mo) or Tungsten (W), onto the ceramic surface which making use of glass phase immigration between alumina ceramic and metallic paste under high-temperature sintering, then the metallic layer could adhere to the ceramic surface tightly. Then the ceramic surface owns both properties of ceramic and metal. This process is called as "ceramic metallization". In order to elevate the wettability of metallization layer, a following metal coating ( like nickle) will be plated via electroplating, firing method. Then it could achieve the brazing process well.

Our facility has been producing various of customized metalized alumina Ceramic insulators in different purities of alumina, different bespoke shapes, different colors and different surface treatment. You will find an amazing solution there for your demanding application.

Standard types of metalization

● Alumina ceramic body + silver (Ag) plating directly

● Alumina ceramic body + molybdenum (Mo/Mn) metallization

● Alumina ceramic substrate + direct bonding copper (DBC method)

● Alumina ceramic body + molybdenum (Mo/Mn) metallization + nickel (Ni) plating

● Alumina ceramic body + tungsten (W) metalization + gold (Au) plating

Prime characteristics

1. High bonding/brazing strength with ideal vacuum tightness between the assembly

2. With diamond-like hardness to be 85 HRA and superb compressive strength

3. Superb insulation strength and volume resistivity that fit for high voltage, high current applications

4. Chemical inert, anti-aging even if it works in a variety of severe conditions, free of rust forever

5. More than 10 times wear resistance in comparison with stainless steel, it leads to a long service lifespan.

Typical applications

Metalized ceramics are widely used in electronics, high-vacuum technology, sensors, and medical fields, like gas discharge tubes, electron tubes, vacuum interrupters, feed-throughs, medical linear accelerators/ power tubes, photomultipliers,X-ray tubes, and pressure sensors