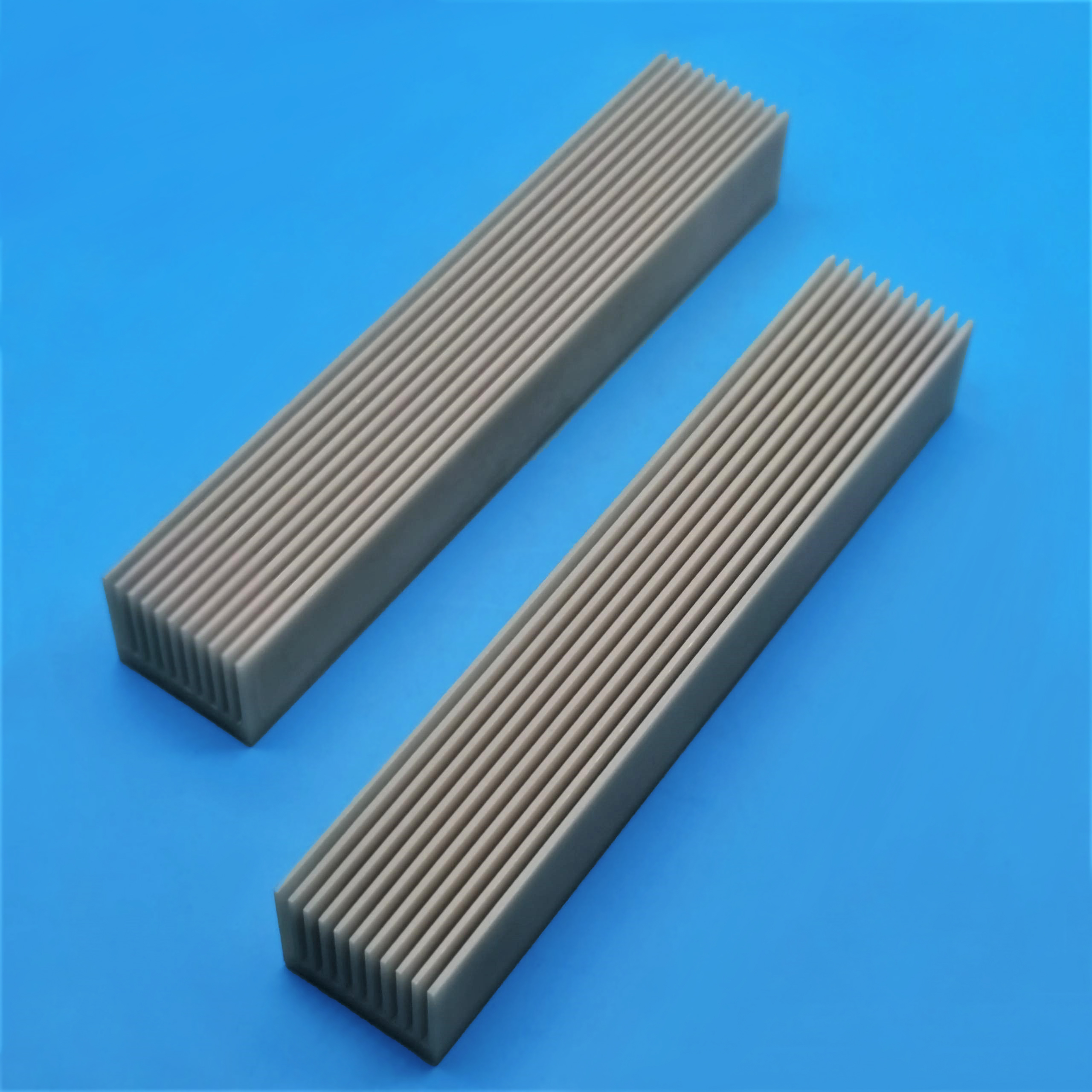

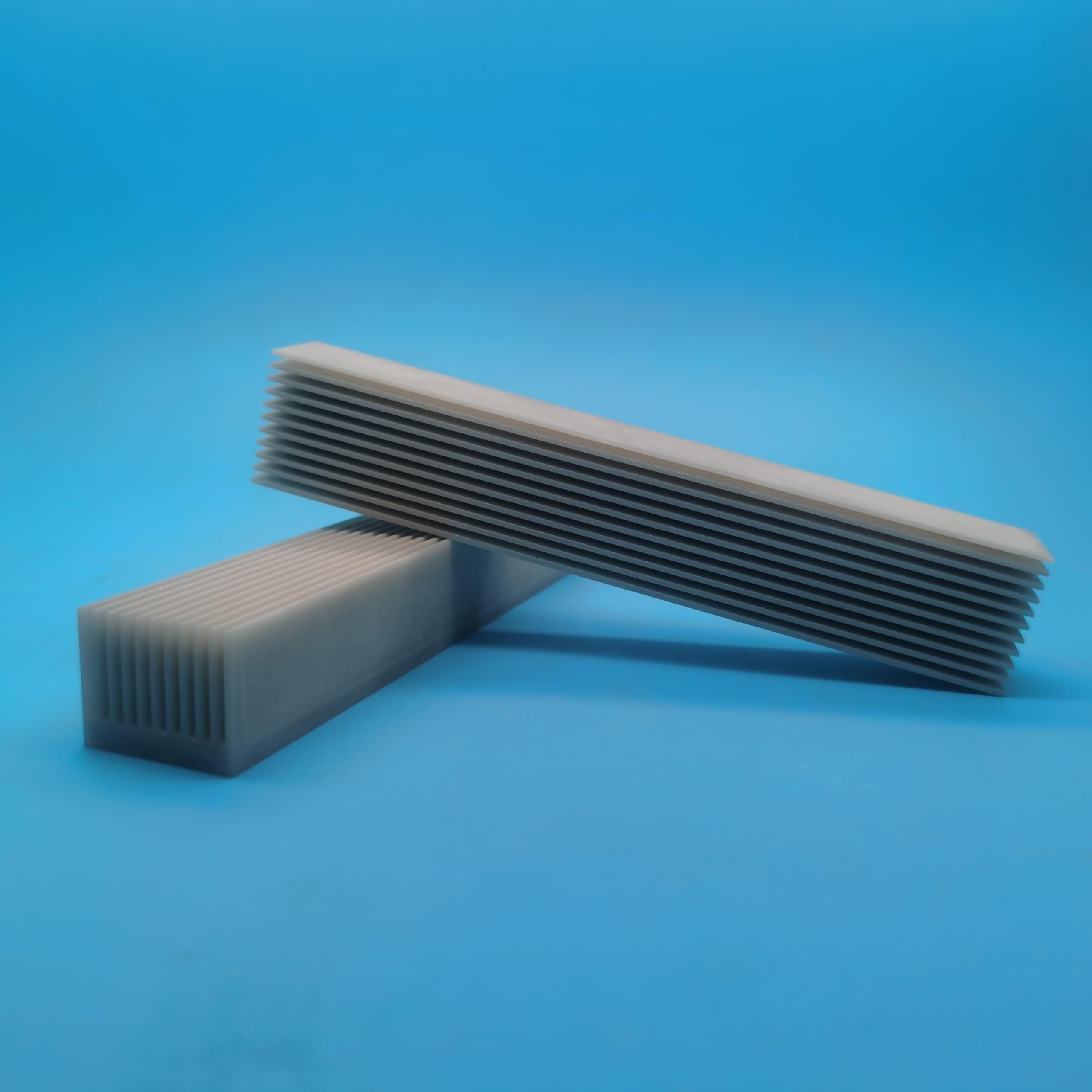

Jinghui Ceramic can produce various specifications of aluminum nitride ceramic heat sinks with high thermal conductivity and good heat dissipation. Thanks to our extensive live inventory, we can ship your parts quickly so you can get started on your project. Please contact us for customization.

Aluminum nitride ceramic heat sink is a product with excellent thermal conductivity. It can quickly conduct the heat generated by electronic equipment to the heat sink, and then dissipate it to the outside through the heat sink. This can effectively reduce the temperature of electronic components and improve the performance and life of the device. Aluminum nitride ceramic heat sinks have been widely used in cooling systems of various electronic equipment, such as LED lights, electric vehicles, computers, etc.

Commonly used materials for heat sinks

At present, the commonly used materials for heat sinks mainly include metal, ceramics, plastics and insulating materials.

1. Metal: Metal (such as aluminum alloy, copper) is a common heat dissipation material and can be used in heat sinks, radiators, heat pipes and other heat dissipation equipment.

Aluminum alloy heat sink is currently the most widely used heat dissipation material in the computer industry. It has the advantages of good heat dissipation effect and low manufacturing cost. At the same time, aluminum itself is lightweight and easy to carry and install, but it also has problems such as poor heat dissipation and easy corrosion.

Copper heat sink is a highly efficient heat dissipation material. Its thermal conductivity is better than that of aluminum alloy heat sinks. Copper has high stability and is not easily corroded. However, the manufacturing cost of copper heat sinks is very high.

2. Ceramics: Ceramic materials are more durable than metals under high temperatures and pressures due to their special chemical and physical properties. Ceramic heat dissipation materials are suitable for high-speed operation equipment, such as semiconductor coolers, vacuum tubes, radar devices, etc. However, ceramic materials cost more and are susceptible to cracking due to impact and vibration.

3. Plastics: For example, nylon materials have better thermal conductivity among plastics and good corrosion resistance, and can be used in a wide temperature range. However, plastic materials do not have the same high strength and high temperature resistance as metal and ceramic materials, and are susceptible to softening.

4. Insulating materials: Insulating materials such as resin and silica gel are a type of organic material. They are used to isolate circuits and protect electronic devices. They can be used in high-voltage and high-temperature electronic equipment. However, due to its poor thermal conductivity, appropriate thermal design needs to be carried out during product design and production to obtain optimal heat dissipation performance.

Why choose aluminum nitride ceramic heat sink?

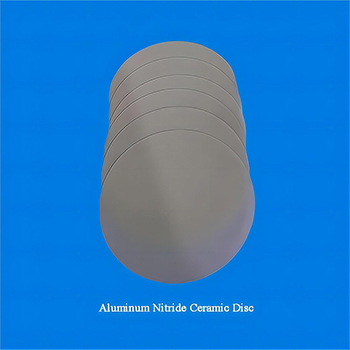

Commonly used ceramic heat sink materials include beryllia (BeO), alumina (Al2O3) and aluminum nitride (AlN).

- Alumina (Al2O3) has low thermal conductivity and its thermal expansion coefficient does not match that of silicon.

- Although beryllia (BeO) has excellent performance, its powder is highly toxic.

- Aluminum nitride (AlN) has high thermal conductivity, good thermal shock resistance, and good mechanical properties at high temperatures. Although it is a bit more expensive, it is still considered the most ideal ceramic heat sink material.

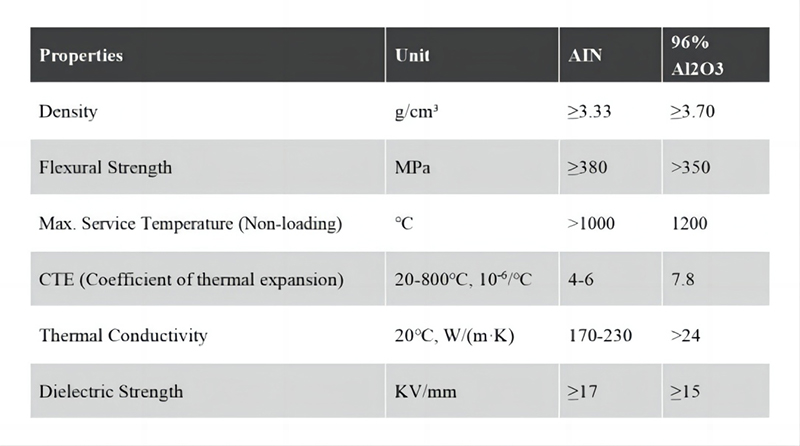

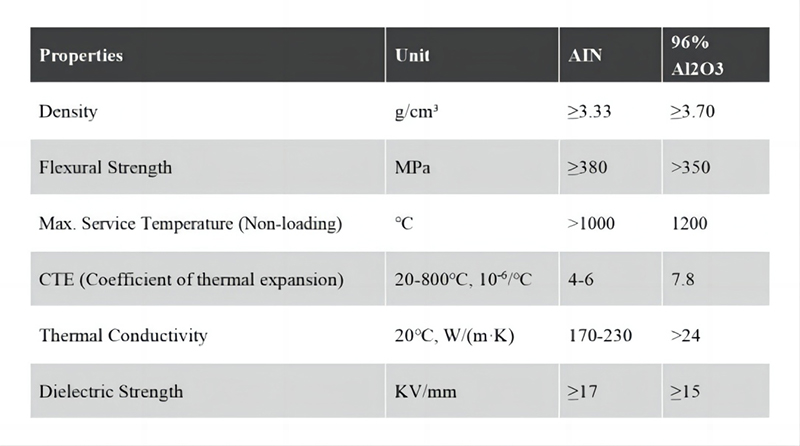

Performance comparison

1. The thermal conductivity of AlN is 7-8 times that of Al2O3, second only to SiC and BeO among ceramic materials.

2. The mechanical strength and dielectric strength of AlN are superior to Al2O3.

3. The thermal expansion coefficient of AlN is close to Si.

Therefore, people hope to use aluminum nitride instead of beryllia or alumina as ceramic heat sink materials for high-density and high-performance electronic packaging technology.