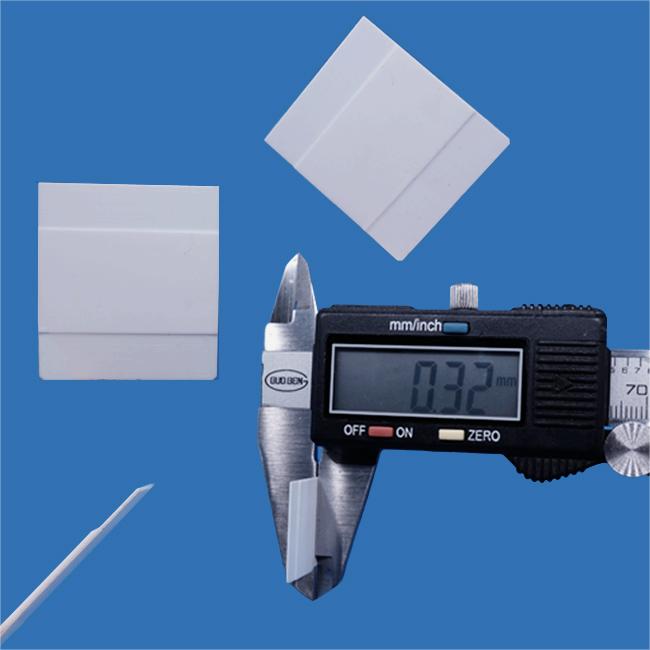

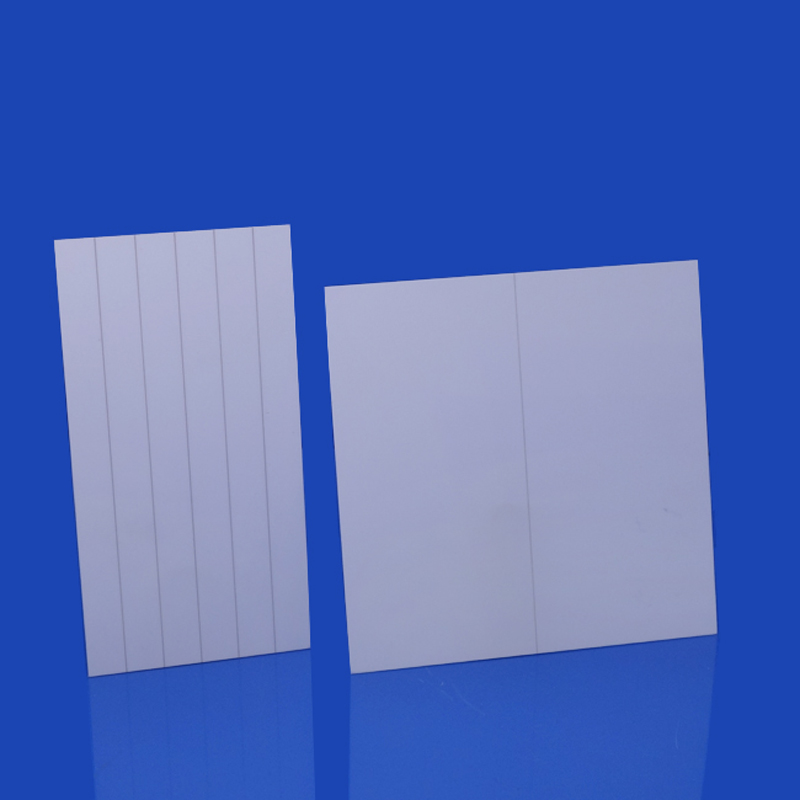

(1) Alumina ceramic substrates are generally prepared by tape casting method. For products with high requirements on size and precision, secondary processing is required after firing, such as grinding, polishing, drilling, cutting, etc.

(2) Alumina ceramic substrates have high hardness and brittleness, so care needs to be taken to avoid collisions and stress concentrations during processing to prevent the substrate from cracking or being damaged. In addition, appropriate cutting tools and parameters should be selected during processing to ensure processing quality and efficiency.

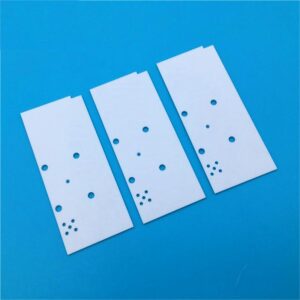

(3) Laser processing technology has the advantages of non-contact, flexibility, high efficiency, easy realization of digital control, high precision, etc., and has become one of the most ideal means for ceramic substrate processing today.

Typical Applications