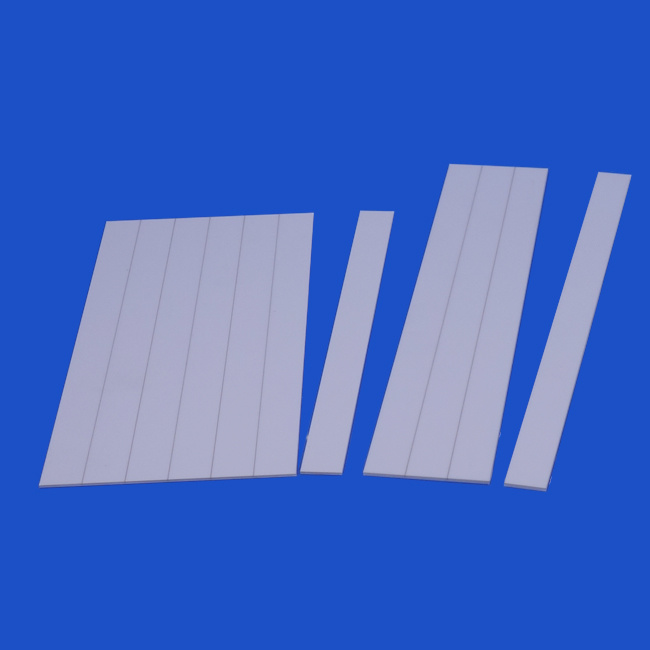

Jinghui Ceramic is a professional ceramic substrate manufacturer from China. We have rich production experience and are committed to meeting the diverse needs of our customers. With advanced production technology, as well as strict quality control measures, we are able to provide alumina ceramic substrates that meet international standards.

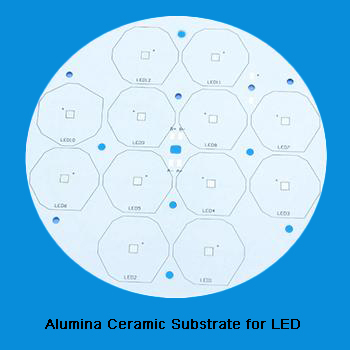

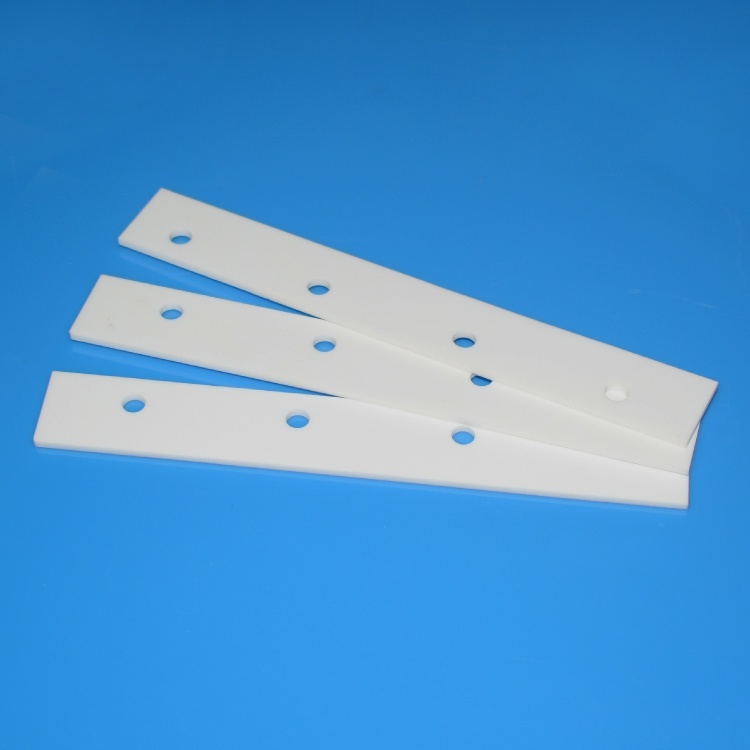

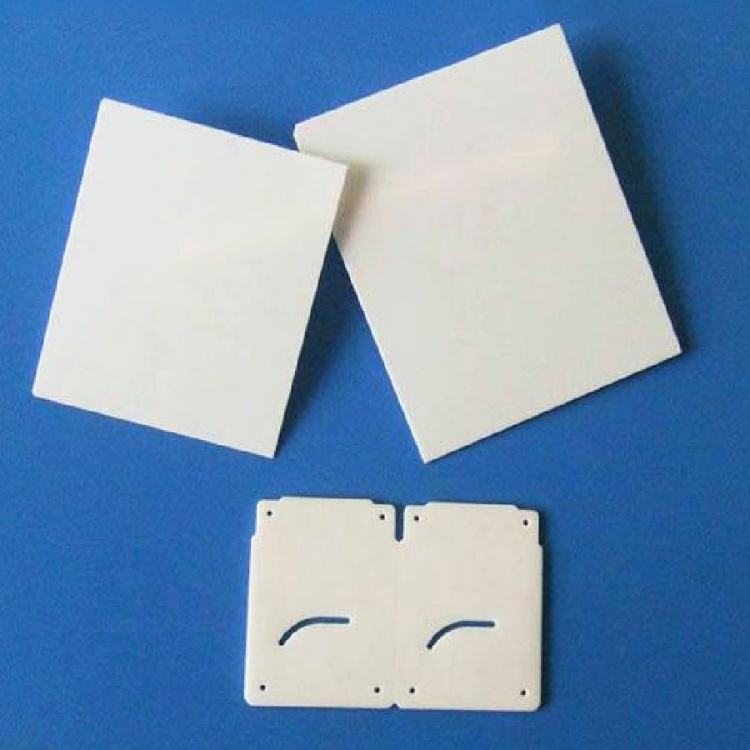

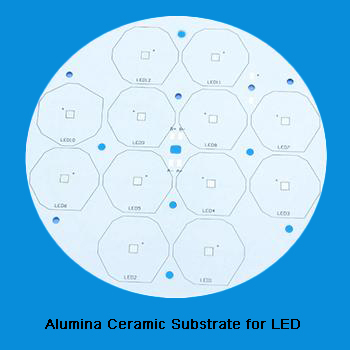

Alumina ((also called aluminum oxide, referred to as Al2O3) ceramic is currently the most widely used ceramic packaging substrate material. It has excellent properties such as high strength, high temperature resistance, thermal shock resistance, electrical insulation and corrosion resistance, and is cheap and easy to obtain. The common alumina substrate is white and is used as LED substrate, high-frequency circuit substrate, etc.

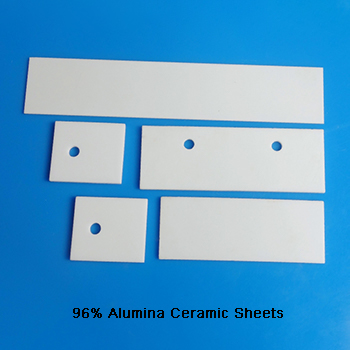

Differences in Alumina Ceramic Sheets of Different Purities

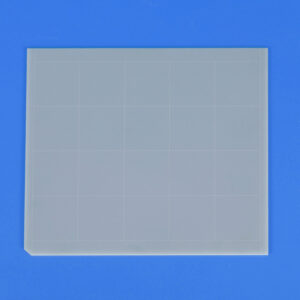

Alumina ceramic sheets can be divided into different models according to purity, such as 90% alumina, 96% alumina, and 99% alumina. The electrical and mechanical properties of alumina ceramic sheets of different purity are different.

The higher the purity, the higher the dielectric constant, the lower the dielectric loss, and the better the finish of the substrate. Generally speaking, the higher the purity, the higher the price of alumina ceramic sheets.

Product Applications

One of the most important applications of high purity aluminum oxide ceramic sheets is in the ceramic substrate industry, used in LED power lighting, semiconductor refrigerators, power hybrid circuits, high-frequency switching power supplies, solid-state relays, lasers and other industrial electronics.