Product Description

We have specialized in producing alumina (aluminum oxide, or Al2O3) ceramic substrates for more than 15 years, under strict quality control, using carefully selected high-purity ceramic materials ranging in purity from 94.4% to 99.6%.

All of these ceramic substrates have extraordinary electrical, thermal and mechanical properties, especially excellent thermal conductivity with a thermal expansion coefficient similar to that of silicon. In addition, one of its unique properties is its excellent surface roughness and thus excellent bond strength with thin and thick film metallization layers, making it an ideal material for various circuit boards.

The conventional molding method we use is tape casting. We offer various thickness options from small sizes to large sizes. With our well-equipped production facilities, we have the ability to go from prototyping to mass production in a short period of time.

Prime Characteristics

1. High dielectric strength, low dielectric constant and small dielectric loss.

2. High thermal conductivity, up to 25W/(m·K) at 25°C.

3. High-quality surface with ideal flatness, warpage and roughness.

4. High hardness and excellent bending and breaking strength.

5. Corrosion-resistant, suitable for various harsh environments.

6. Anti-oxidation, never rust in very humid conditions.

7. Different patterns are easily achieved by laser cutting with precise tolerances.

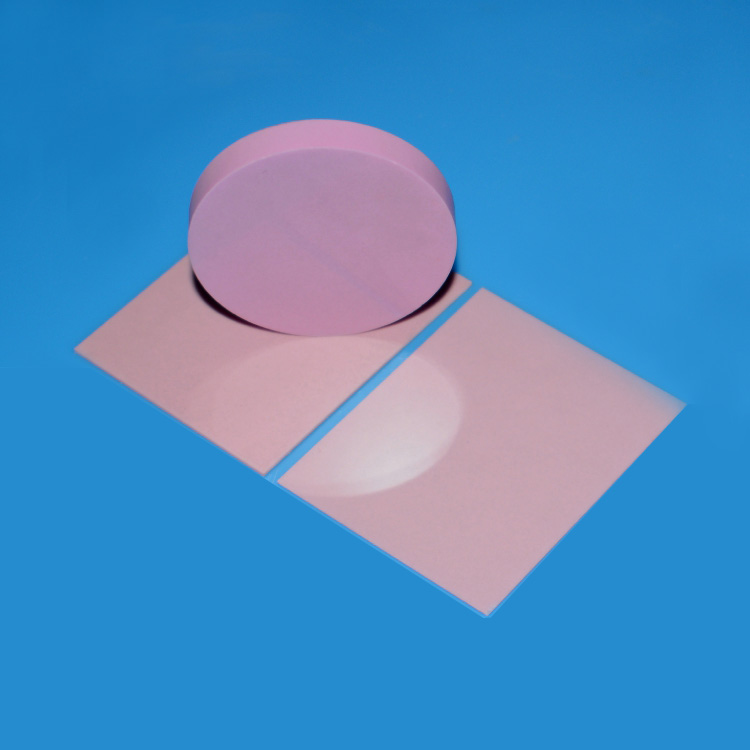

About the Color

Al2O3 often requires coloring in practical applications. We add colored ionic compounds to make alumina products of different colors.

For example, in semiconductor integrated circuits, aluminum oxide used as a package shell should have light-shielding properties. Therefore, the Al2O3 on the back panel of the digital tube is also required to be black to ensure that the digital display is clear. For this reason, Fe2O3, CoO Cr2O3, TiO2, MnO and other colored oxides can be added to Al2O3.

Pink alumina products are made by adding Cr2O3 to Al2O3 ceramics. Since the Cr3+ ions in the solid solution α-Al2O3 lattice have a strong selective absorption of the blue-green color of visible light, it presents a blue-green complementary color, that is, pink.

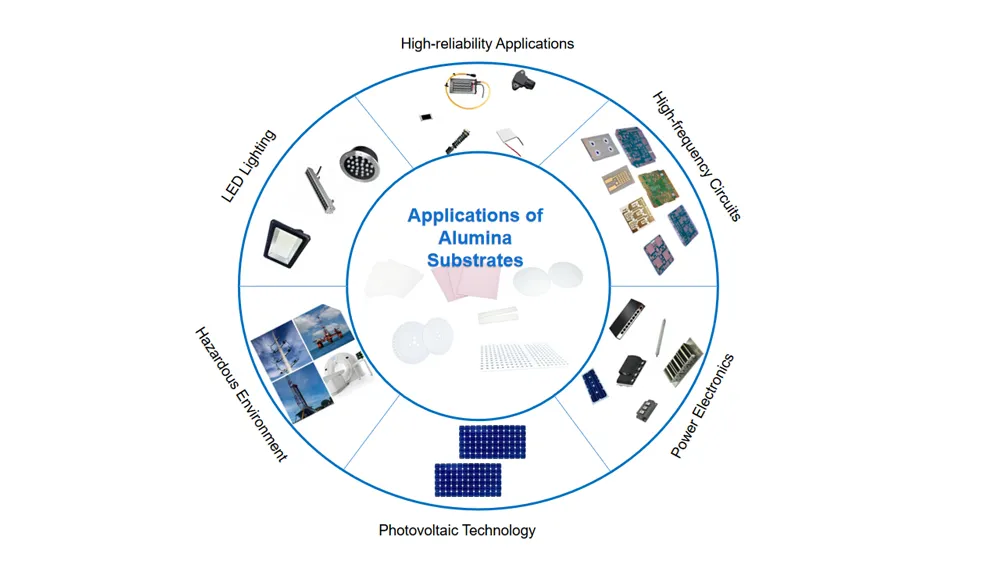

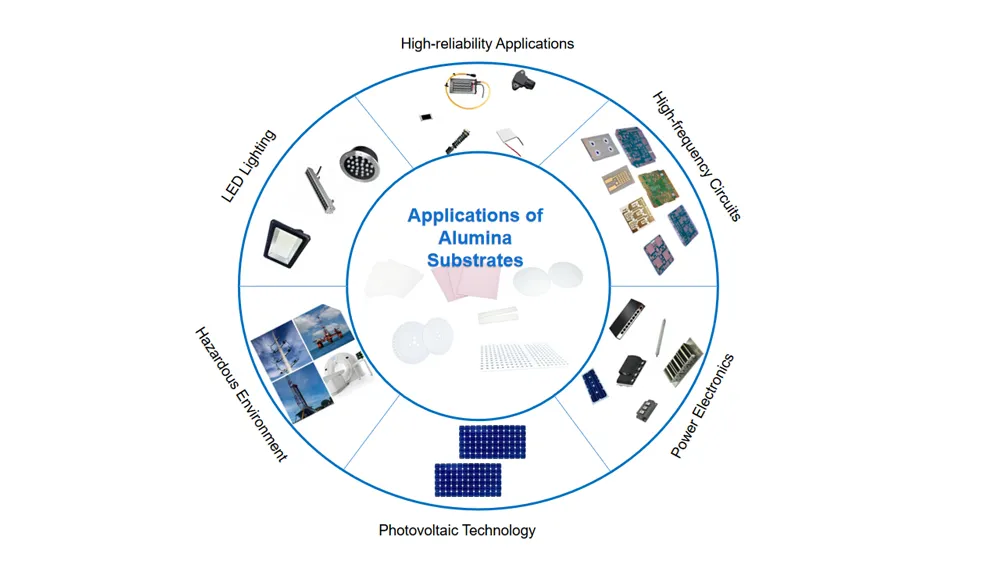

Typical Applications

Remark:

Alumina ceramic substrates are widely used in high power modules, integrated semiconductor circuits as well as photovoltaic technology and LED lighting. Ideal thermal conductivity and fast heat dissipation are of great benefit to practicality and service life.

We also produce:

Packaging and Shipping

1. In order to ensure that the ceramic substrates received by our customers are in good condition, we will design and customize the internal configuration of the packaging.

2. For standard packing scheme, please refer to the picture below.

FAQs (Frequently Asked Questions)

Q1: What sizes are available for the alumina substrates?

The typical largest size available is 280x240mm. Maximum standard thickness is 1.27mm and up to 2.0 mm available upon request. We offer customized products for special requirements.

Q2: What are the main advantages of a ceramic PCB?

The maximum operating temperature of the ceramic substrate exceeds 800°C, the thermal conductivity can reach up to 180W/(m K), the CTE (thermal expansion coefficient) is extremely low, the water absorption rate of the sealed package is 0%, and the signal loss is low. In addition, ceramic circuit boards made by the DPC method can be applied to fine microcircuits.

Q3: What are the available via diameters for alumina substrates?

Round vias with diameters of 0.2mm are available. Square holes and special shape holes are also available per request. Please contact us for details.

Q4: How are the ceramic substrates machined?

We use 100% laser process. This is the best way to ensure precise and clean milling and drilling of advanced ceramic materials.

Q5: What other products do you manufacture?

We also produce metallized ceramics, ceramic seals and high precision pump plunger and pistons besides alumina ceramic substrates.