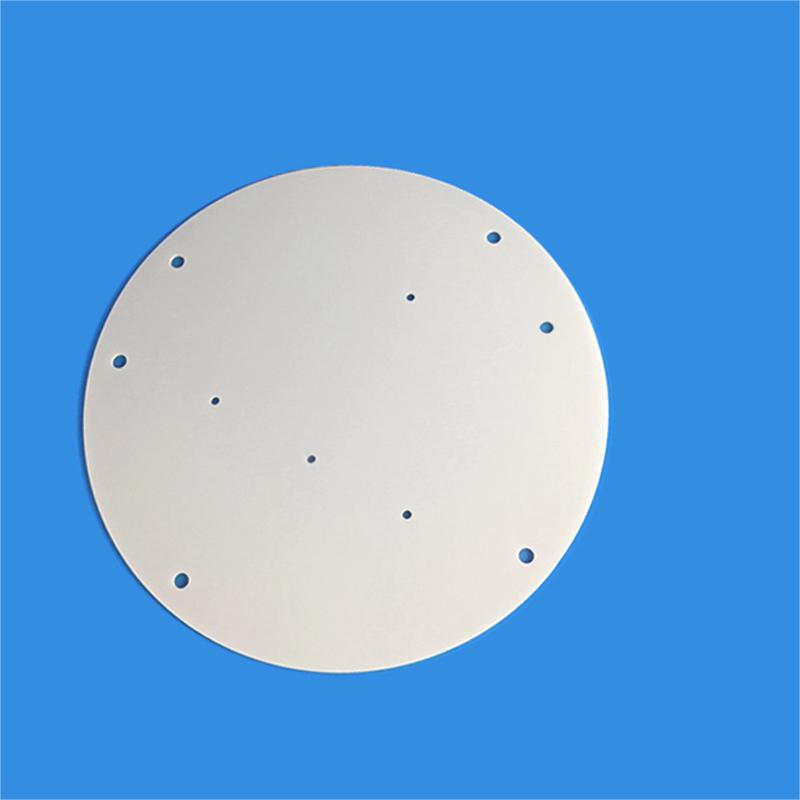

About Aluminum Nitride Ceramic Wafer

Aluminum Nitride (AlN) Ceramic Wafer is a round ceramic disc made of Aluminum Nitride material with excellent physical and chemical properties. Its main features are as follows:

1. Excellent thermal conductivity: it can quickly dissipate heat, effectively reduce device temperature and improve work efficiency.

2. High hardness and mechanical strength: it can withstand certain pressure and impact, and has good durability.

3. Good corrosion resistance: suitable for applications in harsh chemical environments.

4. Stable size and shape: It can maintain high-precision processing requirements and ensure the accuracy and stability of the device.

5. Good insulation performance: it can effectively isolate current and prevent interference and short circuit between electrical components.

6. Wide temperature range: It can maintain stable performance at extreme temperatures, suitable for applications in high and low temperature environments.

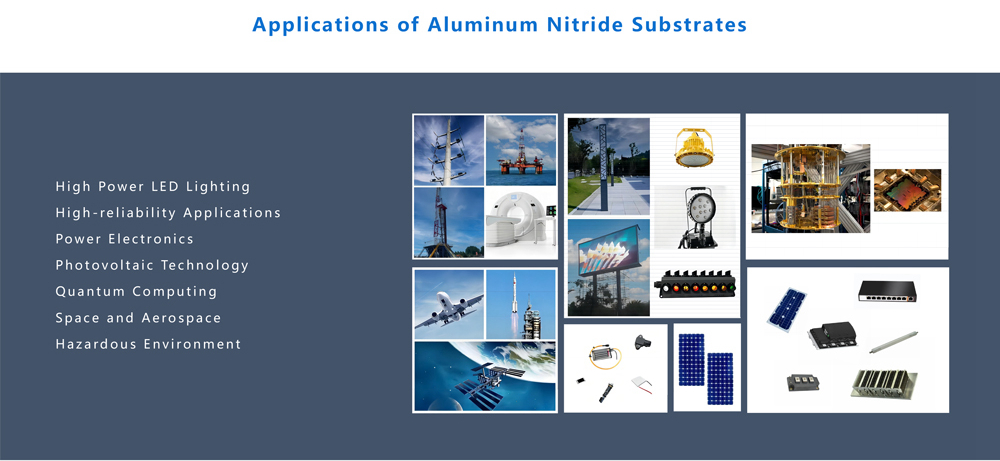

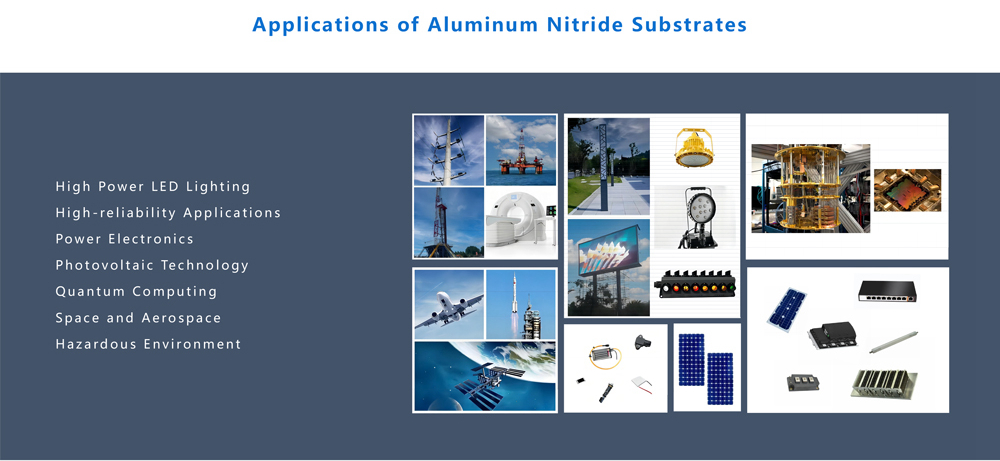

Product Applications

These characteristics of the above-mentioned aluminum nitride ceramic wafers make them widely used in electronics, optoelectronics, aerospace and other fields, especially suitable for the manufacture of high temperature, high frequency, high power electronic devices and heat dissipation devices. Whether in industrial production or scientific research, aluminum nitride ceramic circular substrates play an important role and make important contributions to the development of various industries.

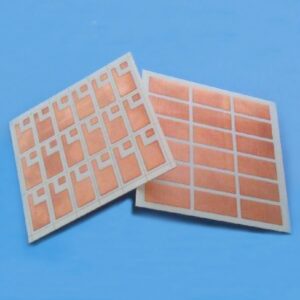

Why Use CNC to Machining AlN Ceramic Substrates

The benefits of machining aluminum nitride (AlN) ceramic substrates with CNC are as follows:

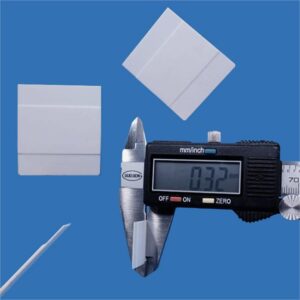

1. High precision: It can realize high-precision processing, ensure the accuracy of the size and shape of the substrate, and meet the engineering requirements.

2. Efficiency: With the characteristics of automation and high-speed processing, it can quickly complete processing tasks and improve production efficiency.

3. Flexibility: It can be adjusted and modified according to different processing needs and design requirements, providing more flexible processing solutions.

4. Good repeatability: the same processing procedure can be accurately repeated to ensure the consistency and stability of each substrate.

5. Complicated processing ability: It can realize the processing of complex shapes and structures, meet various needs, and provide more diversified product choices.

Why Choose Us

Our company has rich experience and excellent ability in the production of aluminum nitride round ceramic substrate products. The following is the introduction of our production capacity:

1. Advanced manufacturing equipment: Our company is equipped with the most advanced CNC processing equipment, including CNC lathes, CNC milling machines and CNC grinding machines. These devices are characterized by high speed, high precision and high stability, and can meet the processing needs of various complex shapes and structures.

2. High-precision processing capability: We have an experienced technical team and high-quality operators, who can process precise size, shape and hole position according to customer requirements. We can ensure that the processing accuracy meets the customer's requirements, and can meet the needs of high-precision industrial applications.

3. Diversified processing methods: In addition to conventional CNC processing methods, we also have other processing methods, such as laser scribing, laser cutting, etc. These processing methods can meet customers' needs for special shapes and structures, and can also improve processing efficiency and production capacity.

4. Strict quality control: Our company pays attention to quality control, and every link in the process from raw material procurement to processing is strictly controlled in accordance with the ISO quality management system. We have complete quality testing equipment and technology to ensure that each product meets customer requirements and international standards.

5. Customized processing capability: We provide customized processing services, and can carry out personalized design and processing according to customer needs. Whether it is size, shape or hole position, we can respond flexibly to provide customers with customized products.

-1024x773.jpg)

-1024x773.jpg)