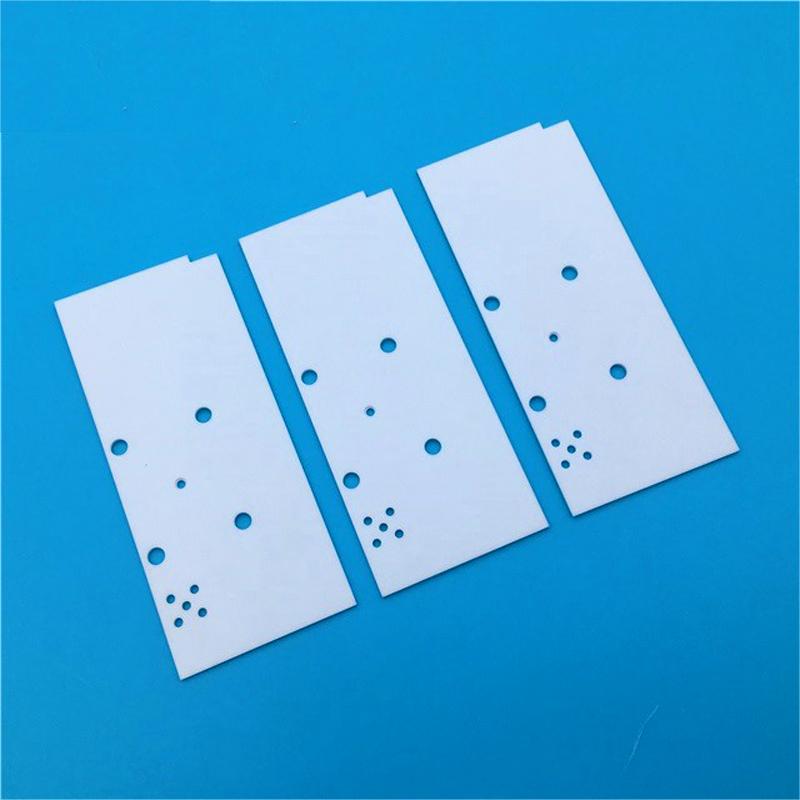

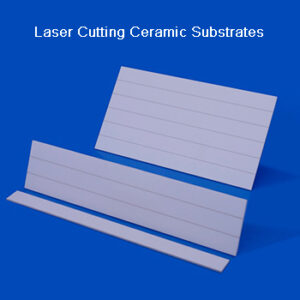

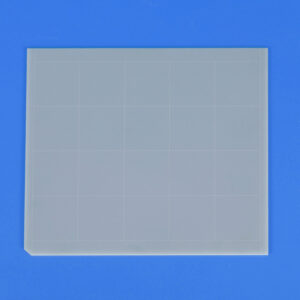

Jinghui Ceramic is dedicated to producing high quality ceramic substrates. Our bare ceramic substrates are available in a wide range of standard and custom thickness, shape, and size. For products that require high dimensional accuracy, we can use various machining methods to process ceramic substrates, such as lapping, polishing, laser scribing, laser cutting, etc.

Ceramic substrate is a special type of PCB substrate. Because its heat dissipation performance, current carrying capacity, insulation, thermal expansion coefficient, etc. are much better than ordinary glass fiber PCB boards, it is widely used in high-power power electronic modules, aviation and aerospace, military electronics and other products. But the disadvantage that we cannot ignore is that the ceramic substrate is brittle.

Traditional machining methods will generate stress during processing, and for thinner ceramic substrates, it is easy to break. With the development trend of light weight and miniaturization, traditional cutting methods can no longer meets people's expectations. As a non-contact processing tool, laser has greater advantages over traditional processing techniques and plays an important role in ceramic substrate processing.