Jinghui Ceramic controls production at all levels, and focuses on providing customers with high-quality products. We produce custom products to meet your professional needs.

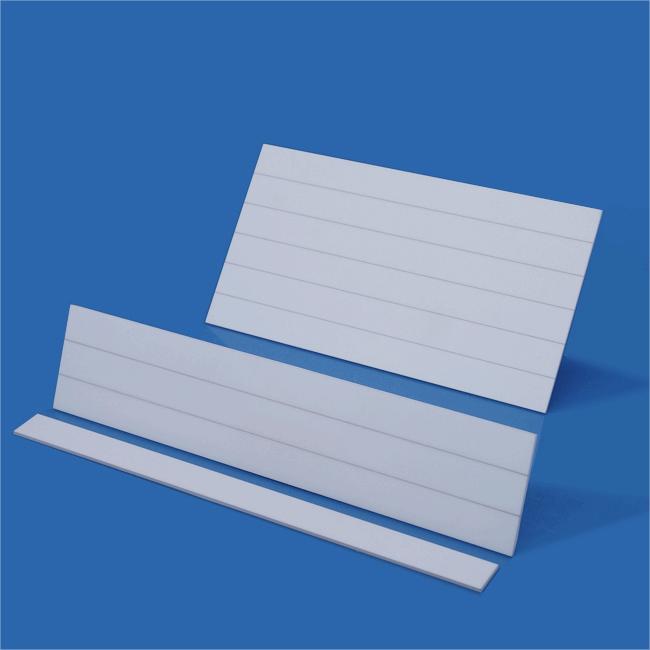

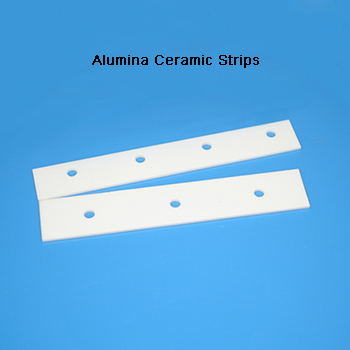

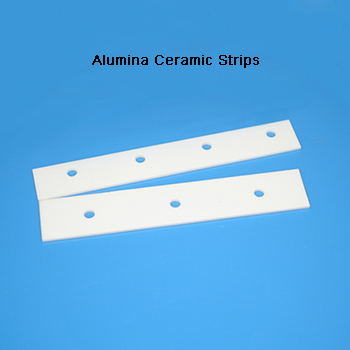

Here we will focus on recommending alumina ceramic strips, which have many excellent properties and have been successfully used in many industries.

1. Excellent insulation performance: Used in the electronics industry to make ceramic substrates, ceramic electrical insulators, electronic materials, etc.

2. High temperature stability: Suitable for high temperature environments such as high temperature furnaces and heat treatment equipment.

3. Chemical stability: Used in chemical equipment, laboratory utensils, etc.

4. Mechanical strength: Used as mechanical parts in mechanical equipment or mechanical systems.

5. Machinability: It can be processed and customized by cutting, grinding, drilling and other processing techniques. The shape and size can be designed according to specific needs to meet the requirements of different application fields.

Production Capability

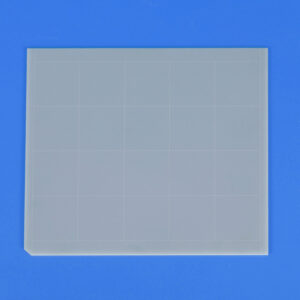

The following is a brief introduction of our company's production capacity in the field of blank ceramic substrates.

| Optional Materials |

Shaping Method |

Specification Availability |

Post-processing Availability |

| Alumina (Al2O3)

Aluminum nitride (AlN)

Silicon nitride (Si3N4)

Zirconia (ZrO2) |

Tape casting |

Max. Size = Length 280mm*Width 240mm

Max. Diameter= 500mm with thickness over than 2mm

Min. Thickness: 0.10mm

Best Roughness: Ra0.05 after polishing |

Lapping

Polishing

Laser scribing

Laser cutting

Metallizing |

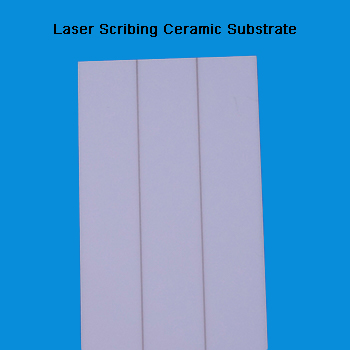

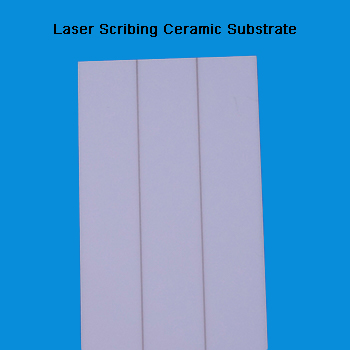

About Laser Scribing

Laser scribing technology uses a high-energy and high-density laser beam emitted by a laser to irradiate the surface of a ceramic substrate, causing thermal deformation, melting or evaporation of the ceramic material, thereby forming thin lines on the surface of the ceramic material. Laser scribing has the following characteristics:

1. High precision: It can achieve very small line width and high-precision scribing, usually in the size range of tens to hundreds of microns.

2. High speed: It can complete the marking task of large area in a short time.

3. Non-contact processing: It will not cause mechanical stress and damage to the surface of the material, avoiding the problems of material rupture and deformation that may be caused by traditional mechanical scribing.

Due to the special properties of ceramic materials (high hardness and brittleness), they generally cannot be processed using traditional processing techniques, and laser is the ideal tool for processing such materials. We provide a variety of services and solutions such as ceramic cutting, drilling, and notching, which correspond to different effects and efficiencies (costs). You can make flexible choices based on quality and price.