How Our Ceramic Parts are Produced?

Jinghui has been focusing on the production and processing of precision ceramic structural parts for more than ten years. As shown below, our product production is mainly divided into 3 steps, forming - finishing - metallization.

1. Forming Method

There are mainly Dry Pressing, Hot Pressing, Isostatic Pressing, and Ceramic Injection Molding (CIM), each of which has its own advantages and disadvantages. We will choose the most suitable forming method on the basis of saving costs and ensuring quality.

2. Finishing Process

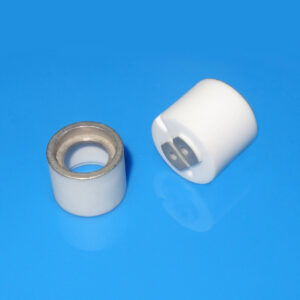

In order to achieve the precision of the product, most ceramic structural parts need further finishing treatment after the sintering process. The main finishing processes we use are machining (lapping, polishing...) and glazing.

3. Metallization Process

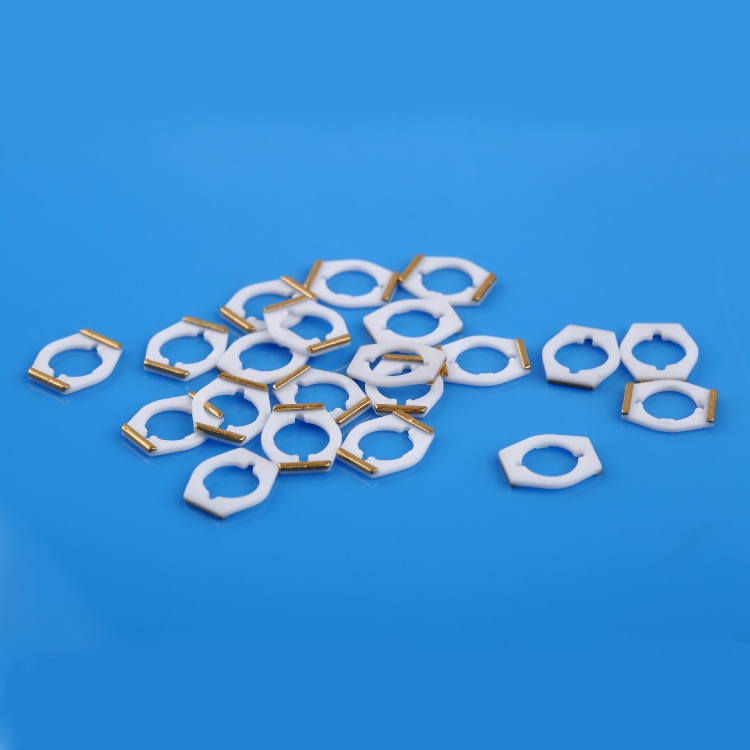

Metallization of ceramics refers to the creation of thin metal layers (films) on the surface of ceramics. After the surface of the ceramic material is metallized, it has both the characteristics of ceramics and the properties of metal.

Which Metallization Processes We Support?

Jinghui is proficient in the surface metallization process of ceramic structural parts such as Mo-Mn method, electroless nickel plating method, silver firing method and W-Au method. Here we focus on the electroless nickel plating method.

Why choose us?

Jinghui is an enterprise specializing in the research and production of precision ceramics. Metallized ceramics are our superior products. They have excellent high-frequency and high-voltage insulation properties, high sealing strength, and good vacuum airtightness.

We hope that we will do our best to improve your product performance and reduce production costs with years of practical experience.