Product Introduction

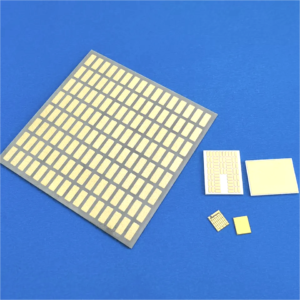

Metallized ceramic substrate with Ni plating is a high-tech product with excellent performance. It uses a ceramic substrate as a carrier, and after a special process treatment, a layer of metal nickel is plated on the surface to form a composite material with excellent heat resistance, corrosion resistance and electrical conductivity.

There are several advantages to nickel-plated metallized ceramic substrates.

First, ceramic substrates have good mechanical strength and heat resistance, and can maintain stable performance in high-temperature environments.

Secondly, the metal nickel layer can provide good electrical conductivity, so that the substrate has excellent electrical properties and signal transmission capabilities in the application of electronic devices.

In addition, the nickel-plated metallized ceramic substrate also has the characteristics of corrosion resistance, wear resistance, and oxidation resistance, and can maintain long-term stability in harsh working environments.

What Substrate Material Is Generally Used?

Nickel-plated metallized ceramic substrates generally use alumina (Al2O3) ceramics or aluminum nitride (AlN) ceramics as the substrate material, and the choice of which substrate to use depends on the specific application requirements and performance requirements. Alumina ceramics are suitable for general high temperature and high frequency applications, while aluminum nitride ceramics are suitable for applications requiring higher thermal conductivity and heat dissipation.

Do Other Metal Layers Need to Be Deposited Prior to Ni Plating?

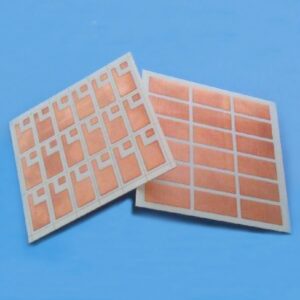

Yes, it is necessary. When nickel-plating ceramic substrates, the underlying metal is often deposited first, and then the metal nickel is deposited to obtain better electrical conductivity and plating quality. This is because the surface of ceramic materials usually does not have good conductivity, and the deposition of metallic nickel needs to be carried out on a base layer with good conductivity.

Copper is a commonly used base metal because of its good electrical conductivity and adhesion, and serves as an intermediate layer for nickel plating. Nickel is used as the underlying metal, mainly to provide better adhesion and prevent the diffusion and reaction of the metal.

Application of Ni-plated Metallized Ceramic Substrates

The emergence of nickel-plated metallized ceramic substrates provides strong support for the development of electronic devices, but also brings new possibilities for technological innovation and progress in other fields.

Ni-plated metallized ceramic substrates are widely used in electronics, telecommunications, aerospace, automotive, medical and other fields. It can be used as the substrate of high-frequency circuits, microwave circuits, power modules, sensors and other devices, and plays an important role in high-speed signal transmission, high-power output and high-precision control.

In addition, the Ni-plated metallized ceramic substrate also has good welding performance and machinability, which is convenient for assembly and processing with other materials, and improves the overall performance and service life of the product.

Our Advantages

Jinghui has more than 15 years of experience in R&D and production of metallized ceramic substrates, and has proofing and mass production capabilities. We continuously promote the improvement and advancement of processes, facilities and equipment, actively seek new opportunities for advanced material technologies, and assist customers in creating new operational value.