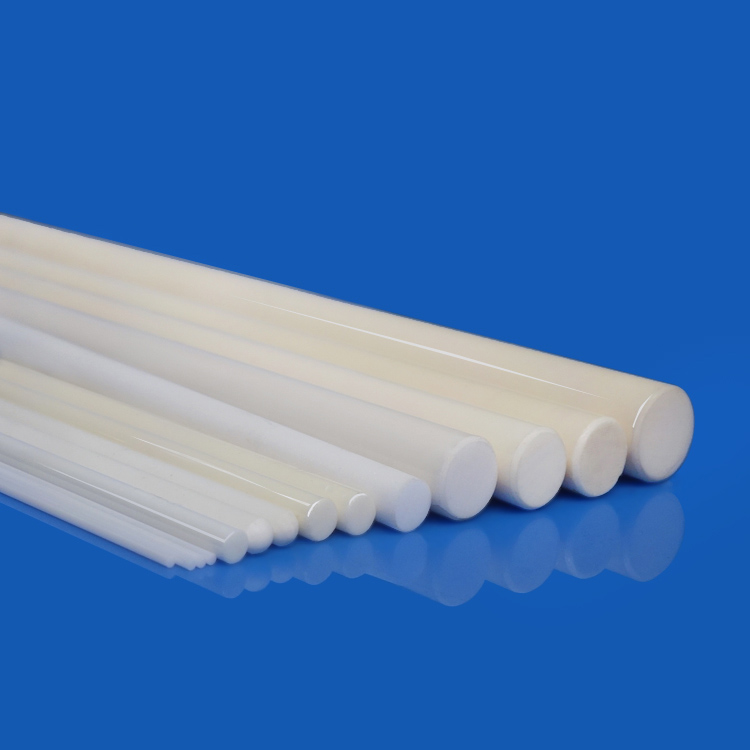

Product Introduction

Alumina ceramic rods are cylindrical rods made of alumina ceramic powder through multiple processes such as molding, sintering, and machining. It has high hardness, high wear resistance, high corrosion resistance and excellent mechanical properties, and is widely used in many fields.

Common processing techniques for alumina ceramic rods are as follows:

1. Drilling: the ceramic rod can be drilled by CNC or laser machine (through hole / counter bore);

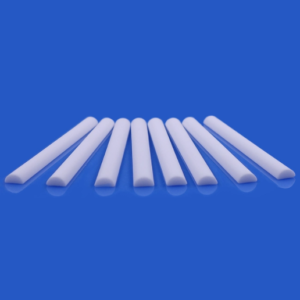

2. Grooving: Grooving is carried out according to the requirements of the drawing, which can be grooved on one side or double-sided;

3. Straightness processing: The straightness has a great relationship with the size of the ceramic rod. The longer the ceramic rod, the easier it is to bend. We can process the straightness according to the requirements of customers. For example, the straightness of the ceramic rod with a length of 100 mm is controlled at 0.1 mm, and the straightness of the ceramic rod with a length of 300 mm is controlled at 0.3 mm;

4. Polishing: After the ceramic rod is sintered, the surface is still relatively rough. It is necessary to use a centerless grinder or other grinding equipment to polish the surface of the ceramic rod. The roughness after polishing can best reach Ra 0.05;

5. Chamfering: it can be mainly divided into 45 degrees, 60 degrees, 90 degrees, etc., and the chamfering of ceramic rods at different angles can be performed by using a grinding wheel;

6. Cylindrical processing: ceramic rods usually require cylindrical grinding, and its roundness can reach 0.002 mm.

Product Features

1. Multiple Specifications

Customized on demand, complete specifications, reliable quality

2. Preferred Material

High hardness, toughness, durable

3. Smooth and Burr-Free

Smooth and bright surface, uniform force, non-slip