About Ceramic Setter Plates

Ceramic setter plate is a common sintering tool, which is widely used in various sintering furnaces, including ceramic product production kilns, glass melting kilns, metal sintering kilns, ceramic sintering kilns, etc. It is an important part of the sintering furnace, which bears the important function of supporting and protecting ceramic products, and also plays a key role in the firing process and product quality. It has the following features and functions:

1. High temperature resistance: Ceramic setters can usually withstand high temperatures above 1000°C. This allows it to carry and conduct heat in the kiln, ensuring that the ceramic is heated evenly and avoids warping and cracking.

2. Chemical stability: Ceramic setters can withstand the erosion of various chemical substances. This prevents it from chemically reacting with the ceramic product during the firing process, ensuring the quality and surface finish of the product.

3. Flatness and dimensional stability: Ceramic setter plates can provide a stable support platform to ensure the shape and size of ceramic products are accurate.

4. Wear resistance: Ceramic setter plates can withstand friction and thermal shock inside the kiln, and have a long service life.

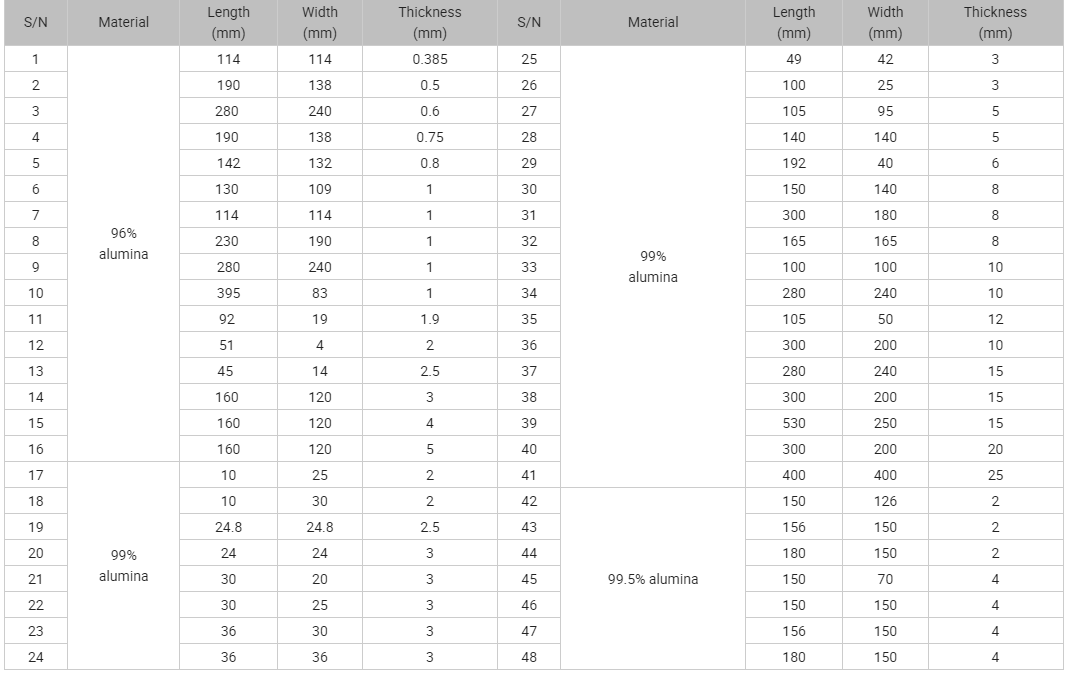

Specifications of our Alumina Setter Plates

We have many selections of al2o3 ceramic plates, refer to the checklist of standard sizes in different purity.

Remark:

All the above big-size ceramic sheets can be cut to specific dimensions per customers' requirements.

Why Choose Us

1. 15 years of experience in OEM and ODM manufacturing, with a reliable professional team.

2. Strong R&D, prototype and mass production capabilities, supporting trial orders and mass production.

3. In-house comprehensive manufacturing type equipment from raw materials to high precision machining.

4. Have a strict quality control system, and operate in accordance with IQC, IPQC, QA, OQC and other operating instructions.

5. Complete pre-sales, sales and after-sales services, and earnestly fulfill each customer's order.