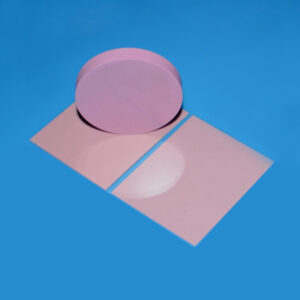

Introduction of Zirconia Ceramic Substrates

Zirconia ceramic substrate has the characteristics of high hardness, high compressive strength, low thermal expansion coefficient, etc., and can operate stably under high temperature and high pressure environment.

Zirconia ceramic substrates have good chemical stability and electrical insulation, and can be widely used in electronics, optoelectronics, thermal electronics and other fields.

In addition, it also has excellent wear resistance and corrosion resistance, can maintain good surface flatness and precision for a long time, and is suitable for various precision machining processes. As an important basic material, zirconia ceramic substrates have broad application prospects in high-tech industries.

Molding Technique of Zirconia Ceramic Substrates

At present, injection molding, dry pressing and tape casting are usually used to produce zirconia ceramic substrates.

1. Injection molding is only suitable for forming thick substrates with a thickness of more than 1 mm.

2. Dry pressing often results in delamination of the green body due to uneven radial and axial pressure distribution during the forming process.

3. Tape casting is suitable for producing thin ceramic substrates with a thickness of 0.2 mm to 3 mm. It has the advantages of fast production speed, high automation, uniform structure and good product quality.

The molding process used for our zirconia ceramic substrates is tape casting. Below is the process flow.

The company has strong processing capabilities. We offer bare ceramic substrates in a variety of raw materials, sizes, shapes and thicknesses. Please contact us today with your specifications.