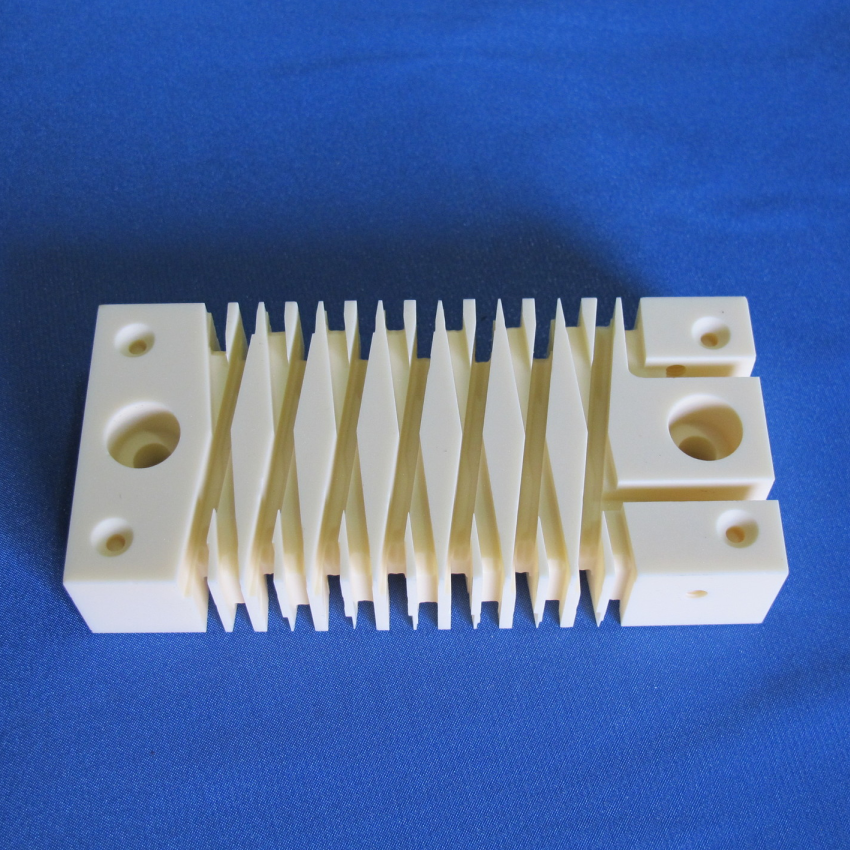

C799 Aluminum oxide (Alumina) has an extensive application due to its versatility and low cost of material than other advanced ceramics. Alumina offers high electrical insulation resistance, high-temperature resistance, strong hardness, wear resistance, and good chemical stability, making it a good material to withstand high temperature and chemical corrosion.

The purity of alumina produced by our factory varies from 75% to 99.8%, and all ceramic parts we supply have dense bodies, which are made by dry pressing, hot pressing, ceramic injection molding (CIM) or isostatic pressing. In order to achieve some special fitting, reduce friction and increase insulation, we provide a series of secondary processing after sintering, including CNC machining, polishing, glazing and metallization.

We produce all kinds of alumina ceramic tubes, ceramic rings, ceramic discs, ceramic rods, ceramic arms, ceramic wire guides, etc. Whether it is proofing or mass demand, we believe we can provide you with an ideal solution.