About Aluminum Nitride Ceramic Plates

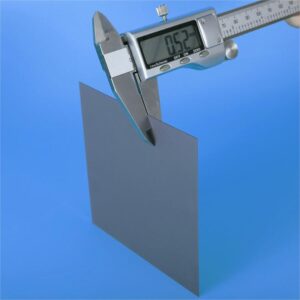

Aluminum nitride ceramic plate is a high-performance ceramic material, which has excellent thermal conductivity characteristics, which are much higher than traditional ceramic materials, making it ideal for thermal management in high temperature environments. Its high thermal conductivity can quickly conduct heat, effectively reduce thermal stress and temperature gradient, and improve the thermal stability and reliability of the material.

In addition, aluminum nitride ceramic plates also have excellent mechanical properties, including high hardness, high strength and excellent wear resistance, enabling them to withstand high loads and resist wear. It also exhibits good chemical stability and corrosion resistance, can resist the erosion of acid, alkali and other chemical media, and is suitable for many harsh environments.

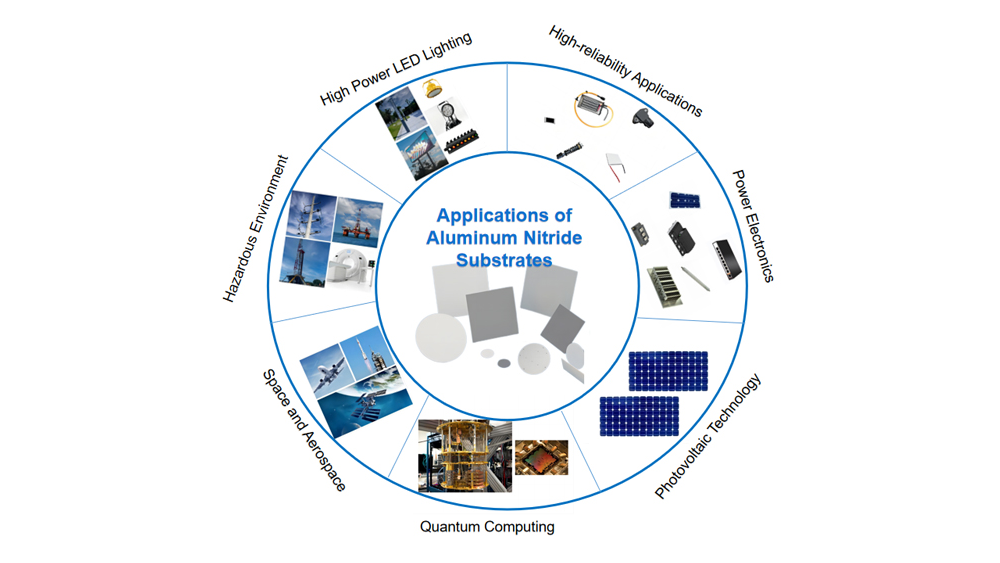

Application of Aluminum Nitride Ceramic Plates

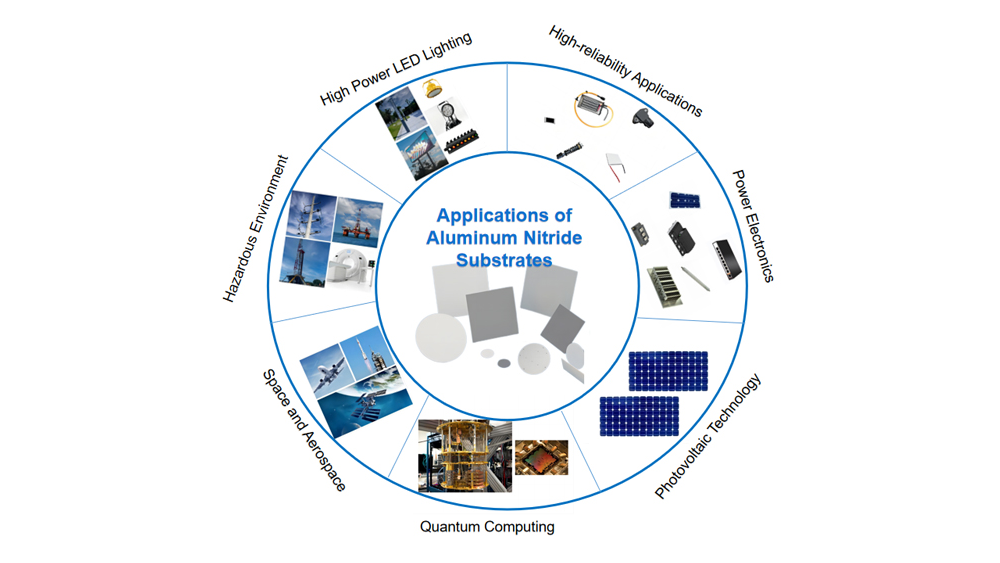

Aluminum nitride ceramic plates have a wide range of applications in many fields.

In the electronics industry, it can be used to manufacture heat-dissipating substrates for high-power electronic devices, providing excellent thermal conductivity and improving equipment efficiency and reliability.

In the field of optoelectronics and optics, aluminum nitride ceramic plates can be used as heat sinks and optical windows for high-power lasers to ensure the stability and performance of the equipment.

In addition, it can also be used in structural materials for high-temperature furnaces, combustion chambers and other high-temperature equipment, as well as sensors and electrodes in the chemical industry.

Production Process of Aluminum Nitride Ceramic Plates

The production process of aluminum nitride ceramic plates usually includes the following steps:

1. Raw material preparation: use high-purity aluminum nitride powder as the main raw material, and add appropriate amount of additives and regulators as needed. The selection and preparation of raw materials has a significant impact on the performance and quality of the final product.

2. Forming: The raw material powder is mixed, pressed and formed to form a ceramic body with the required size and shape.

3. Sintering: Place the formed ceramic body in a high-temperature sintering furnace for sintering. During the sintering process, by controlling factors such as temperature, time and atmosphere, the powder particles in the ceramic body are combined into a dense aluminum nitride ceramic material.

4. Processing and finishing: The sintered aluminum nitride ceramic plate usually needs to be processed and finished to achieve the required size, shape and surface quality.

5. Inspection and quality control: Inspection and quality control are carried out on the produced aluminum nitride ceramic plates to ensure that they meet the specified technical requirements and standards.

6. Application of the final product: After the above steps, the aluminum nitride ceramic plate produced can be used in the fields of electronics, optoelectronics, and chemical industry, for heat dissipation substrates, optical windows, and structural materials for high-temperature equipment.

How to Drill Holes on Aluminum Nitride Ceramic Plates

The aluminum nitride ceramic plate has a dense structure, but has a certain degree of brittleness, especially for some thin ceramic plates, which are easily broken, so laser processing equipment is generally used for cutting and drilling.

The laser processing technology has the advantages of non-contact, flexibility, high efficiency, easy realization of digital control, and high precision. It has become one of the most ideal methods for ceramic substrate processing today.

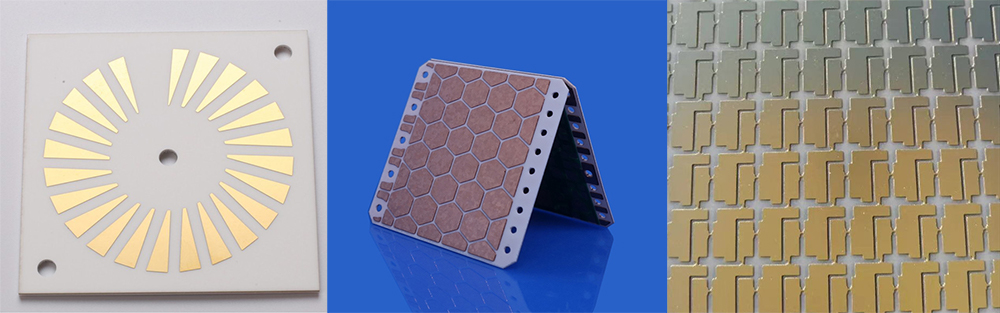

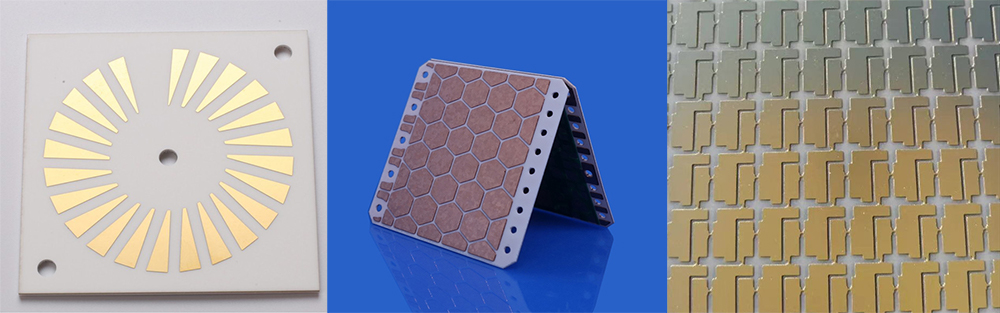

Why Choose Us

Beside bare ceramic substrates, we also manufacture metallized ceramic PCBs. Metallized ceramics is one of our advantageous products.