In this article, we will explore the differences in thermal conductivity of advanced ceramics and their different application areas. If you are considering using ceramic materials in your thermal management applications, this article may help you.

内容目录

How is the Thermal Conductivity of Advanced Ceramics?

Thermal conductivity is an important parameter for measuring the thermal conductivity of materials. This concept is widely used in architecture, engineering, and electronics. Thermal conductivity reflects how fast heat is transmitted through a material, usually expressed in W/(m·K) units. Most advanced ceramics have low thermal conductivity, resulting in slower heat transfer.

Is Higher Thermal Conductivity Better?

Materials with high thermal conductivity can conduct heat more effectively and have better thermal conductive properties, but it is not the higher, the better. In some cases, we need to slow down or avoid heat transfer. For example, to maintain a comfortable indoor temperature in a building, it is necessary to slow the heat conduction from the outside air into the room. In addition, materials with lower thermal conductivity are also needed in refrigeration equipment to slow down the transfer of heat.

Thermal Conductivity of Advanced Ceramics Vs Metals

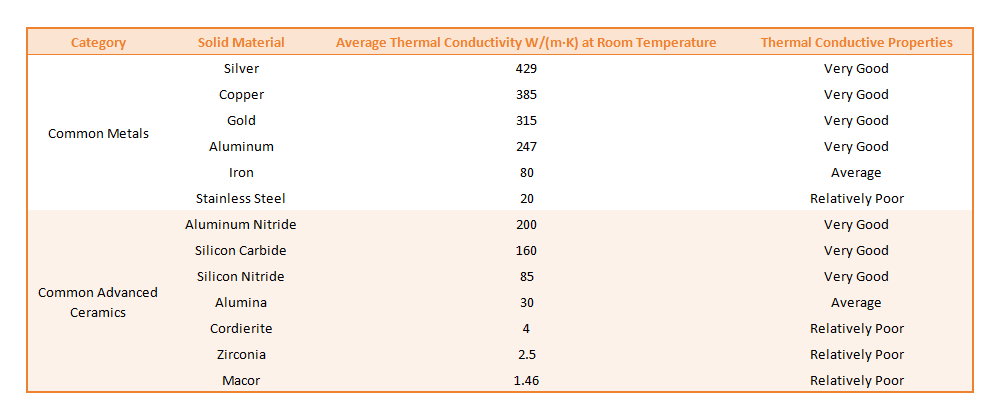

There are apparent differences in thermal conductivity between advanced ceramics and metals. Metals usually have higher thermal conductivity and are considered excellent thermal conductors. The thermal conductivity of common metals, from high to low, can be roughly arranged into silver, copper, gold, aluminum, iron, stainless steel, etc. Among common metals, silver has the highest thermal conductivity. Its thermal conductivity is generally 429W/(m·K), followed by copper at 385W/(m·K), and then gold at 315W/(m ·K).

Advanced ceramics are non-metallic inorganic materials with much lower thermal conductivity than metal materials. Most advanced ceramics are considered to be poor conductors of heat or thermal insulators. For example, the thermal conductivity of oxide ceramics, the most common advanced ceramics, is mainly limited to 30W/(m·K), which is a big gap compared with the three most common high thermal conductivity metals: gold, silver, and copper.

Why Advanced Ceramics?

Metal materials are widely used in heat conduction due to their excellent thermal conductivity. However, advanced ceramics are more popular in some specific application scenarios than metal materials.

For example, thermally conductive ceramics have become an excellent substitute for metal materials in the electronic and electrical fields. This is because, in addition to materials with good thermal conductivity to dissipate heat, electronic products also need materials with good insulation properties to isolate circuits to ensure the safety of electronic products. Metals do not have the critical characteristic of electrical insulation, and only advanced ceramics meet the requirements (most advanced ceramics have electrical insulation).

Although the thermal conductivity of most ceramic materials is lower than that of metals, the thermal conductivity of some thermally conductive ceramics is very close to or even exceeds that of some metal materials in practical applications. For example, aluminum nitride ceramics is one of the few materials with high thermal conductivity and electrical insulation. Its thermal conductivity can be as high as 230W/(m·K), close to metal aluminum’s 247W/(m·K). The thermal conductivity of silicon carbide ceramics is 120-200W/(m·K), close to the 173W/(m·K) of metal tungsten, higher than the 116W/(m·K) of metal zinc, and much higher than the 80W/(m·K) of metal iron.

Application of Advanced Ceramics in Heat Conduction

Different advanced ceramics have different thermal conductivity properties. Some are good thermal insulation materials, such as Macor glass ceramics, zirconia, and cordierite ceramics. In contrast, others are good thermal conductors, such as aluminum nitride, silicon carbide, and silicon nitride ceramics.

High Thermal Conductivity Ceramic Materials

Common high-thermal-conductivity ceramic materials include polycrystalline diamond ceramics (PCD ceramics), beryllia, aluminum nitride, silicon carbide, and silicon nitride. They all play an important role in high-power electronic devices, heat-dissipation materials, and thermal management, especially in applications that require effective heat dissipation.

Aluminum Nitride AlN

Aluminum nitride ceramics have excellent thermal conductivity, generally 170-230W/(m·K). They are an ideal heat dissipation material, so they are often used in heat sinks, substrates, and packaging in electronic equipment. In the fields of LED lighting, power modules, semiconductor manufacturing equipment, etc., aluminum nitride ceramics help improve the efficiency and reliability of electronic components.

Silicon Carbide SiC

Silicon carbide ceramics have high-temperature thermal conductivity. Its thermal conductivity is generally 120-200W/(m·K). It is often used to manufacture structural parts for high temperatures, semiconductor circuit heat sinks, and heat exchange systems for industrial furnaces in the steel, metallurgy, and other industries.

Silicon Nitride Si3N4

The thermal conductivity of ordinary silicon nitride ceramics is generally 20-30W/(m·k). However, by optimizing the preparation process and adjusting the material composition, high thermal conductivity silicon nitride ceramics can be prepared, with a thermal conductivity of up to 80-90W/(m·k). They are widely used in many fields such as semiconductor packaging, electronic equipment heat dissipation substrates, and insulation layers of high-performance electronic equipment.

Low Thermal Conductivity Ceramic Materials

Common low-thermal-conductivity ceramic materials include Macor glass ceramics, zirconia, and cordierite. These can be used as thermal insulation materials in thermal protection and insulation applications.

Macor Glass Ceramics

The thermal conductivity of Macor ceramics is low, generally around 1.46W/(m·K), and it is considered a thermal insulator. Macor’s low thermal conductivity enables it to optimize the thermal environment of optical windows, ensuring stable operation of optical systems at extreme temperatures. It is also suitable for high-precision optical device manufacturing.

Zirconia ZrO2

Zirconia ceramics have excellent thermal insulation properties, and their thermal conductivity is usually low, about 2-3W/(m·K). They are mainly used in oxygen sensors, thermal substrates for fuel cells, solid oxide fuel cells, and high-temperature heating elements.

Cordierite 2MgO·2Al2O3·5SiO2

Cordierite ceramics’ thermal conductivity is about 3-5W/(m·K), and they are widely used for some occasions that require thermal insulation. For example, they can be used as insulation boards in building materials, thermal insulation layers in thermal equipment such as ceramic heaters and high-temperature kilns, and thermal insulation and heat preservation components of some precision instruments.

Conclusion

High thermal conductivity ceramic materials such as aluminum nitride, silicon carbide, and silicon nitride are often used in heat dissipation applications. In contrast, low thermal conductivity ceramic materials such as Macor glass ceramic, zirconium oxide, and cordierite are often used in thermal insulation applications. Understanding the thermal conductivity of different advanced ceramics helps engineers choose the suitable material for thermal management.